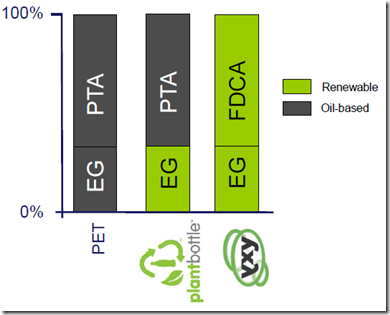

In our July 9, 2012 post we discussed the initiative driven by Coca Cola to develop bio-based plastics for beverage containers. The first phase of this massive project has resulted in the Plant BottleTM which is made using bio-PET where the ethylene glycol starting monomer is made from renewable sources. The Plant Bottle contains approximately 30% bio-based carbon. But the project doesn’t stop there. Coca Cola has established three R&D partners (Virent, Gevo, and Avantium) to drive to a 100% biobased PlantBottle.TM As you recall, the Plant BottleTM used bio-based ethyleye glycol (EG) to make PET. The next piece of the puzzle is to find a synthetic route to bio-based terephthalic acid (PTA). The Virent approach uses soluble carbohydrate starting materials and the Gevo approach uses fermentable sugars to produce bio-terephthalic acid (bio-PTA). The Avantium YXY approach uses C6 sugars to produce furanics, then furandicarboxylic acid , which when polymerized with bio-EG will form bio PEF, a totally new, 100% biobased polymer. YXY is a trademark of Avantium (www.avantium.com) of the Netherlands. The following figure provides a graphical summary:

In our July 9, 2012 post we discussed the initiative driven by Coca Cola to develop bio-based plastics for beverage containers. The first phase of this massive project has resulted in the Plant BottleTM which is made using bio-PET where the ethylene glycol starting monomer is made from renewable sources. The Plant Bottle contains approximately 30% bio-based carbon. But the project doesn’t stop there. Coca Cola has established three R&D partners (Virent, Gevo, and Avantium) to drive to a 100% biobased PlantBottle.TM As you recall, the Plant BottleTM used bio-based ethyleye glycol (EG) to make PET. The next piece of the puzzle is to find a synthetic route to bio-based terephthalic acid (PTA). The Virent approach uses soluble carbohydrate starting materials and the Gevo approach uses fermentable sugars to produce bio-terephthalic acid (bio-PTA). The Avantium YXY approach uses C6 sugars to produce furanics, then furandicarboxylic acid , which when polymerized with bio-EG will form bio PEF, a totally new, 100% biobased polymer. YXY is a trademark of Avantium (www.avantium.com) of the Netherlands. The following figure provides a graphical summary:

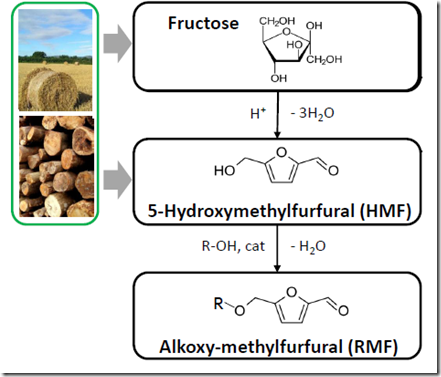

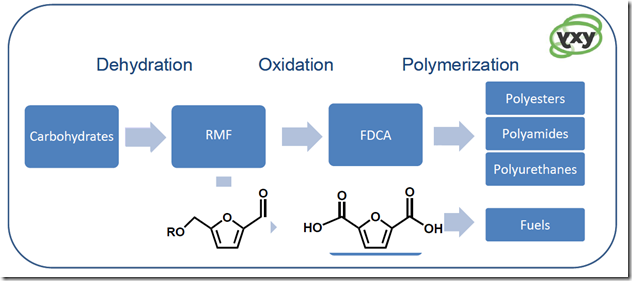

This post will focus on the Avantium approach to a fully bio-based polyethylene furanoate (PEF). Avantium has discovered and patented a revolutionary chemical, catalytic process that allows for the economic production of furanics based on a wide range of carbohydrates. The YXY process converts biomass from various sources into the building blocks of alkoxy-methyfurfural (RMF) using a dehydration process in the presence of alcohols (R-OH) and catalysts:

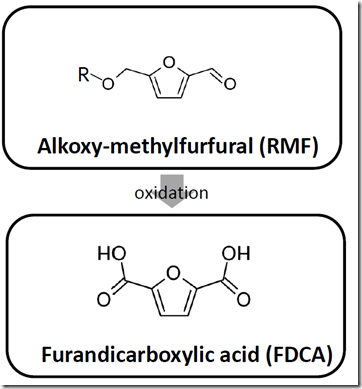

The process then converts the alkoxy-methylfurfural (RMF) to furandicarboxylic acid (FDCA) via an oxidation process:

The overall process can be summarized as follows:

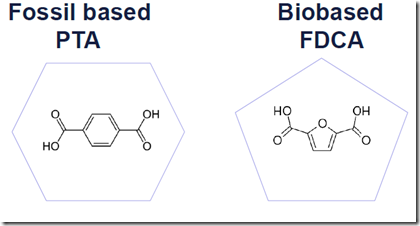

Furandicarboxylic acid FDCA is polymerized in the presence of ethylene glycol (EG) forming polyethylene furanoate (PEF) yielding a high performance engineering thermoplastic capable of multiple applications. The difference in PET and PEF can be seen in the following graphic:

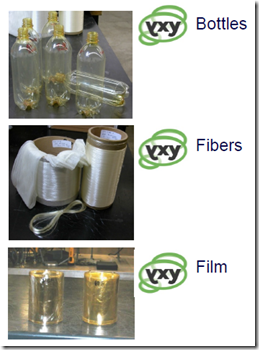

The Avantium product line called YXY PEF can be used to produce:

Bottles on a commercial blow molding line using PET molds

Bottles on a commercial blow molding line using PET molds

Fibers spun on commercial fiber lines

Films processed on commercial film extruder equipment

Another driving force behind PEF is not only the potential to have a high performance polymer made from 100 renewable sources, but PEF will compete on performance. Specifically PEF has very good barrier properties (hard to achieve with most bio-based polymers)

- O2 barrier – 6 times greater than PET

- CO2 barrier – 3 times better than PET

- H2O barrier – 2 times better than PET

PEF also has interesting mechanical properties compared to PET

- Higher Tg (glass transition temperature)

- Lower Tm (melting point)

- Higher modulus

So one might ask, sounds good but what about recycling? PEF can be recycled and incorporated into the PET recycle streams at up to 5% PEF with no affect on the recycled PET performance.

So one might ask, sounds good but what about recycling? PEF can be recycled and incorporated into the PET recycle streams at up to 5% PEF with no affect on the recycled PET performance.

Avantium currently has a pilot plant operational with capacity of 40 tons per year in Geleen, the Netherlands, and has plans for a commercial plant to come onstream in 2015 (40-50 kilo tons per year) and a full-scale industrial plant becoming operational in 2017-2018 (300-500 kilo tons per year). Avantium has made significant investments in R&D (especially catalyst development), pilot plant operations and has plans in place for large-scale commercial production.

References:

1) Images from “Latest Advancements in Biobased Materials and Partnerships; YXY Green from Within, by Peter Magnus, Avantium; presented at the Bioplastics Conference in San Francisco, June 2012.

2) Furfural chemistry images from “Acid catalysed alcoholysis of lignocellulose; Towards second generation furan-derivatives,” by Ruud J.H. Grisel (ECN), Jan Kees van der Waal (Avantium), Ed de Jong (Avantium) and Wouter J.J. Huijgen (ECN); presented at COST Action CM0903 (UBIOCHEM), 3rd workshop, Thessaloniki (Greece), November 1-3, 2012.

Jeff,

I’ve been following Avantium’s YXY progress for a few years now and while I’d be delighted to see PEF emerge as a 100% renewable resource based, economically competitive polymer having superior performance properties to those of PET, I’m a bit intrigued by your comments about commercialisation. You mention a ~50 tkpa plant in operation in 2015 and up to 500 ktpa production around 2017. I immediately went to the Avantium website seeking corroboration of this timetable, but found nothing. Is this someone’s wishlist or is it real?

An article from 10-12-2015 in the financieele dagblad (Dutch Newspaper) it is stated that the current production is 20 ton and the new plant to be realised in 2017 is 5 kton and a multiple of that the years after.

What is the melting temperature of PEF? What is the crystallization rate relative to PET? Is that a problem? Any interest in FDCA polyesters made with C3 and C4 diols?

Geoffrey, ADM and DuPont are making polytrimethylene furnaoate (PTF) which uses the 3 carbon diol, propanediol. DuPont uses the same diol with PTA to make its sorona PET for carpet and other uses. I would expect similar comparisons.

This is really useful, thanks.

In this post you absolutely right because you have some great tips to find a recycle plastics granules. This post is really useful for all. It’s such a great blog for all and me. Thanks for sharing this best information to us.