Guest Post by Dr. Robert (Bob) Humphreys

Engineers are without a doubt the most important people in a modern, technologically advanced society such as the one we enjoy in the USA. Virtually every step in the daily lives of every person in the country is impacted or made possible by something an engineer did, is doing, or will do. Engineers work on mundane projects such as automating yogurt manufacturing to complex projects such as advanced computer chip design to huge projects such as design and supervision of infrastructure construction to critical operations such as supervising electricity generation and distribution throughout the grid. Many challenges engineers face would seem hopelessly insurmountable to the average person. A prototypical example of such a challenge is automated sorting of waste plastics for recycling. The remainder of this post and the next post will focus how engineers have dealt with this dynamic and complex problem. We will focus on current commercial technologies since huge advances in automated waste separation have been made since the early days of municipal waste collection and recycling and, as usual, emphasis will be on the USA.

The Challenge of Plastic and Other Waste Separation

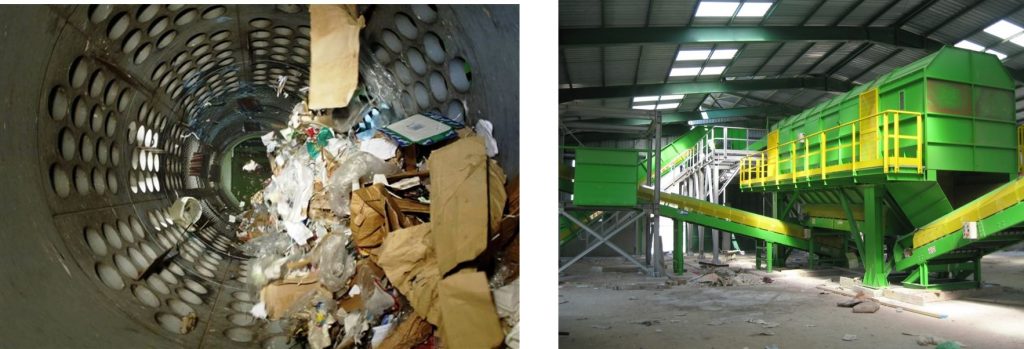

The challenge a waste processing engineer faces is exemplified by the two images above. The left-hand image is typical municipal solid waste (MSW) is placed by people in a bin for weekly trash collection. The right-hand image is mixed recyclables, also known as single-stream recyclables, such as a homeowner might place in the recycle bin for weekly collection. MSW typically contains everything that finds its way into a trash bag, including food scraps, food containers, paper products, plastic packaging film, vacuum cleaner bags, and anything else people discard in the household trash. Contents of single-stream recyclables vary with local collection practices but can contain newspaper, paperboard, cardboard, plastic bottles and other rigid plastic containers, glass containers, and aluminum and steel cans. The challenge is to separate the MSW and single-stream recyclables efficiently into material that can be sold for recycling, converted into useful energy, or landfilled.

Two problems add to the complexity of separation. For MSW, the composition is often moist or wet because of food scraps and other residues. For single-stream recyclables, containers often are contaminated with residual food materials. For both types of waste, some discarded items can cause havoc in any separation operation, such as toxic or flammable materials, dirt and rocks, electronic components, batteries of various kinds, mixed plastic items such as toys, steel parts, wood, and large plastic films and sheets, to name a few. All of these items must be dealt with in any waste separation operation that will produce separated streams of post-consumer plastic as commercially valuable products. In many cases, such contaminants are manually removed even in automated municipal waste processing facilities (MSPF).

As if all of the above wasn’t complex enough, waste separation is a dynamic problem, with the composition of municipal waste streams changing significantly over time. Waste stream composition has changed over decades from paper, cardboard, glass containers, and steel cans and little plastic to much less paper and cardboard, migration of cans from steel to aluminum, plastic replacing glass for most food bottles, and massive growth of plastic films and containers. This mix continues to evolve unpredictably, necessitating that modern waste sorting operations be designed to be flexible. Indeed, many waste processing facilities designed a few decades ago have become obsolete because they cannot cope with the current mix of waste (1).

Preliminary Separation Operation: Pre-Sorting at MSW Processing Facilities

Even if a locality has single-stream collection services that provide consumer-based separation of recyclables, a substantial amount of potentially valuable recyclable items still make it into MSW. In a nutshell, consumer separation is not perfect; recyclable items that may require significant cleaning often are discarded in MSW and confusion about recycle rules result in recyclable items being discarded (2). A large amount of valuable recyclable material can be isolated from typical MSW (1, first document).

Most MSW typically arrives at a mixed waste processing facility (MWPF) in household plastic trash bags. These bags are usually polyethylene film and invariably are coated on the interior with sticky or liquid food waste, making them unsuitable for recycling. Nevertheless, they must be opened to release the bundled trash for separation. This can be accomplished in several ways, but modern technology involves a bag opener designed to tear open bags, release the contents, and discard the film while minimizing clogging of the apparatus with residual film. Images of one type of bag opener and one type of trash bunker-feeder with attached bag opener are shown below.

We note that before bag opening, it may be necessary to remove large objects from the mix, such as plastic furniture, toys, electronics, and other objects that should not pass through the bag opener. If necessary, this process is usually manual.

Preliminary Separation

All of the trash from opened bags is deposited on a moving belt. The waste then passes to one or more units designed to separate smaller fragments, food waste, dirt and stones, and other small debris from larger objects. As usual, different equipment designs are available to perform the separation. An example is a trommel screen, which rotates to disperse the trash thoroughly (see images below); several trommels of different screen sizes can be used in a series to separate the debris into different size ranges.

This equipment usually includes a bins under the units to capture waste material that fall through the screen. Larger waste items, which includes most rigid and film plastics, paper, paperboard and cardboard pass on to the next sorting step.

2D/3D Separation and Metal Removal

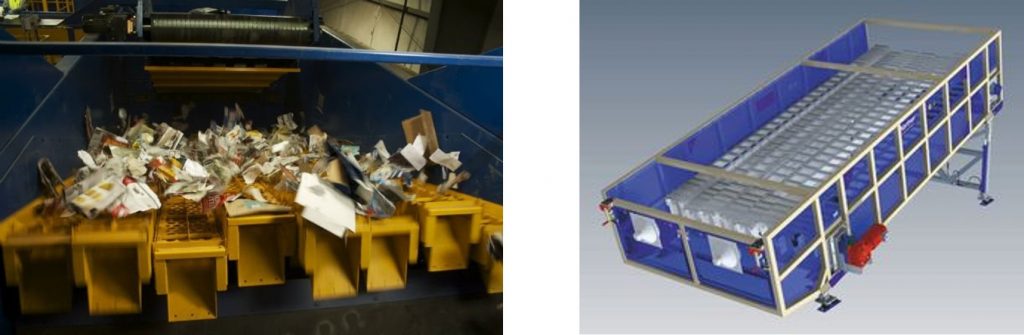

Much of the material exiting the trommel separation consists of paper and cardboard, rigid plastic containers and film, glass containers, and metal containers. This mix can be separated into flat objects (plastic film, paper and paperboard, cardboard) and 3D objects (containers of rigid plastics, glass, and metals) in a ballistic separator. A ballistic separator is basically a set of moving elements on a long, inclined track that move such that the elements propel the mixed waste in the upward direction on the incline. The incline is steep enough that flat (2D) objects such as paper, cardboard, and plastic film are propelled upwards while the 3D objects such as bottles and cans fall back down the incline. This process allows amazingly efficient separation of the waste into separate lots of 2D and 3D materials. Videos of the operation of ballistic separators can be found readily online and are well worth the time to watch this process work. Images of several units are shown below.

At this point, rigid plastic containers, including bottles, are still mixed with glass and metal, so the mix now proceeds on a moving belt to stations that separate this mix. We should point out that much of the equipment described in this post was originally developed for industries such as mining and, therefore, is relatively simple in design and extremely durable, which is critical to economical operation of municipal waste separation facilities.

We will describe the separation of this mixed waste and final separation of the different plastics into streams with commercial recycle value in the next post. Mixed waste at this point is quite similar to single-stream recyclable waste that is separated by consumers and collected by local municipalities, so the next post is relevant to separation of this waste, too.

References and Comments

- Waste sorting references:

- Changes in MWS and MWPF: Evolution of mixed waste processing facilities 1970-today

- Equipment used in MWPF: Supplemental report: the evolution of mixed waste processing facilities- technology and equipment guide

- Recycling information form a waste processing industry leader (Waste Management): Leading change: 2016 sustainability report

- Also, in spite of warnings, fines, and education through the media, plastic waste, paper, and aluminum cans still accumulate along streets and highways, particularly in areas of high population density. People who produce this litter are unlikely to be more conscientious about sorting recyclables.

I have enjoyed reading the information about waste management. Really, entire discussion is more helpful and more effective too. I am very glad to go through this kind of helpful article. Thanks for sharing a nice article.