Today we will start a new series on polymer composites. There are many types of composites including polymer composites, metal matrix composites and ceramic composites. The focus of this series will be on composites made using polymeric resins. Polymer composites are ubiquitous. Many of us don’t realize the many applications of composite materials from aerospace, sporting goods, marine applications, wind energy, electronics, and the list goes on. This post will provide an introduction to composite technology and subsequent posts will provide more detailed discussions of specific composite technologies.

Today we will start a new series on polymer composites. There are many types of composites including polymer composites, metal matrix composites and ceramic composites. The focus of this series will be on composites made using polymeric resins. Polymer composites are ubiquitous. Many of us don’t realize the many applications of composite materials from aerospace, sporting goods, marine applications, wind energy, electronics, and the list goes on. This post will provide an introduction to composite technology and subsequent posts will provide more detailed discussions of specific composite technologies.

Let’s start with a definition of a composite. Merriam-Webster online dictionary defines composite as: something that is made up of different parts. This definition is very broad, so let’s narrow this down to what are typical polymer composites. Polymer composites are mixtures of two materials that result in synergistic properties.

Most polymer composites consist of:

- Continuous phase or matrix which is typically the resin or polymer phase

- Discontinuous phase with is typically a reinforcement (such as glass or carbon fibers, silica fillers, etc.)

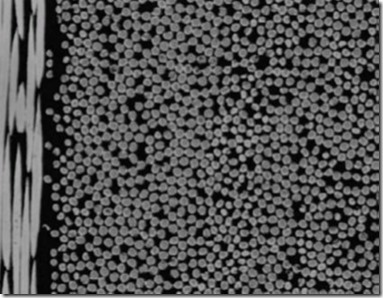

The image below shows a cross-section of a long glass fiber reinforced polymer composite. The circular fibers on the right are coming out of the plane and the fibers on the left side of the image are running in the plane. The black area between the fibers is the resin continuous phase.

Image courtesy of Prof. Brent Strong, “Introduction to Composite Materials” Brigham Young University.

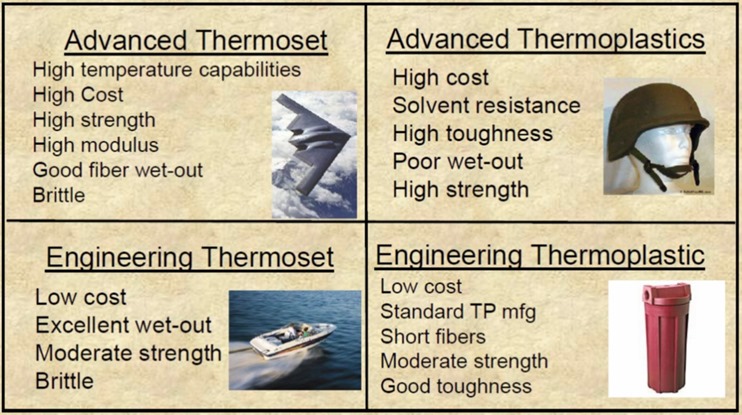

Composites can be categorized into two main types; advanced composites and engineering composites. Additionally polymer composites can be made with either thermoset and thermoplastic resin matrices.

Image courtesy of Prof. Brent Strong, “Introduction to Composite Materials” Brigham Young University.

The main differences between the advanced and engineering composites is typically cost and performance. The beauty of the composite approach is to be able to tailor the performance to the required cost targets. The pressure vessel in the lower right is low cost and can be processed on thermoplastic manufacturing tools while the addition of short chopped fibers imparts strength and toughness as an acceptable cost. High performance aerospace composites deliver very high performance (good fracture toughness and fatigue resistance, high modulus, low weight) but are expensive from a raw materials perspective (carbon fiber or Kevlar fibers along with high performance matrix resins) and complex parts require a sophisticated manufacturing processes such as autoclave or resin infusion.

Polymer composites have the following advantages:

- Lightweight (potentially very high strength-to-weight ratio)

- High modulus and glass transition temperatures

- Ability to tailor properties for a wide range of applications

- Good fatigue resistance

- Easy to mold and bond to a variety of substrates or other composites

- Low thermal expansion (along with ability to tailor the CTE in the X, Y, and Z direction)

- Tailorable electrical properties

- Insulating composites with non-conductive fillers such as glass fibers and silica fillers

- Conductive composites using silver flake or powders

Additionally, polymer composites are not without some disadvantages:

- Advanced composites have a high cost of raw materials

- Complex manufacturing processes are typically required to ensure low voids and porosity

- Long development times

- Low ductility

- Damage susceptibility and the potential for hidden damage (hard to inspect)

- Need careful resin selection to minimize moisture and solvent attack

As we will see in subsequent posts, the advantages of polymer composites out-weigh the potential drawbacks and considerable research and engineering has been completed to minimize the disadvantages. The broad application of composites across many industries is a testament to the utility of polymer composites to deliver structure-property-process-performance benefits in many applications.

what is the difference between EPC & APC ?