Previous posts have covered the various types of mixing geometries such as single, dual and triple shaft mixers and double planetary mixers. The focus was on understanding the mixing physics. There are several ways to improve the efficacy of the mixing process. The last post covered the use of vacuum to accelerate degassing during the mixing process. This post will discuss the use of scaper blades to improve mixing and manage thermal profiles.

For very low viscosity fluids, using the single shaft, cowles mixing geometry will provide adequate fluid movement into the dispersing blade. As the viscosity increases, there may be local heating in the dispersion zone and the material may stagnate near the mixing vessel wall.

Figure 1. Single shaft mixer with cowles dispersing blade.

Achieving proper dispersion requires the material to move into the cowles blade. Filler addition rapidly increases the viscosity and potentially leads to lower material movement into the dispersion zone. The higher viscosity material can stagnate at the vessel wall leading to incomplete mixing. In order to improve the dispersion efficiency, a dual-shaft mixer equipped with sweeper blades (or anchor blades) are used. The anchor blades run in close proximity to the vessel walls and aid in material movement towards the center of the mixing vessel.

The purpose of the anchor blade with a scraper is to more effectively move material from the vessel wall and incorporate into the dispersing zone. The scraper blades are designed to contact the vessel wall, literally “scraping” the material from the wall and moving it into the center of the mixing vessel. Scraper blades can be used to move material from the sides and bottom of the mixing vessel. PTFE (Teflon®) is the main material used for scraper blades due to its low friction coefficient, chemical compatibility, and low rigidity (flexible for good contact with the vessel wall during mixing). PTFE is compatible with most thermoset resins and can be used in food-grade or medical-grade mixing processes. For higher temperature mixing processes, nylon or ultra-high molecular weight polyethylene (UHMWPE) scraper blades may be used.

The main advantage of the scraper blades is to improve heat transfer efficiency in two ways;

- Remove heat during mixing when using a jacketed vessel with a controlled temperature (some thermally sensitive materials generate significant heat on mixing, and thus maintaining the temperature in an acceptable range is required)

- Heat or cooling the mixture. Very high viscosity liquids can be difficult to mix and using a heated jacket to raise the mixing temperature and lower the viscosity would shorten the mixing time and improve dispersion

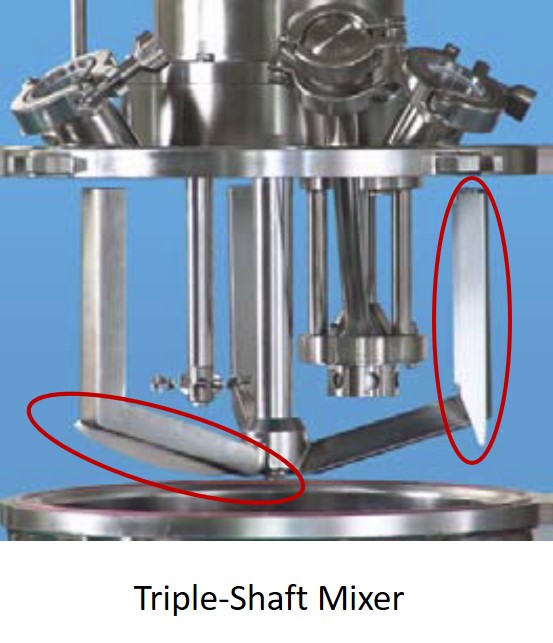

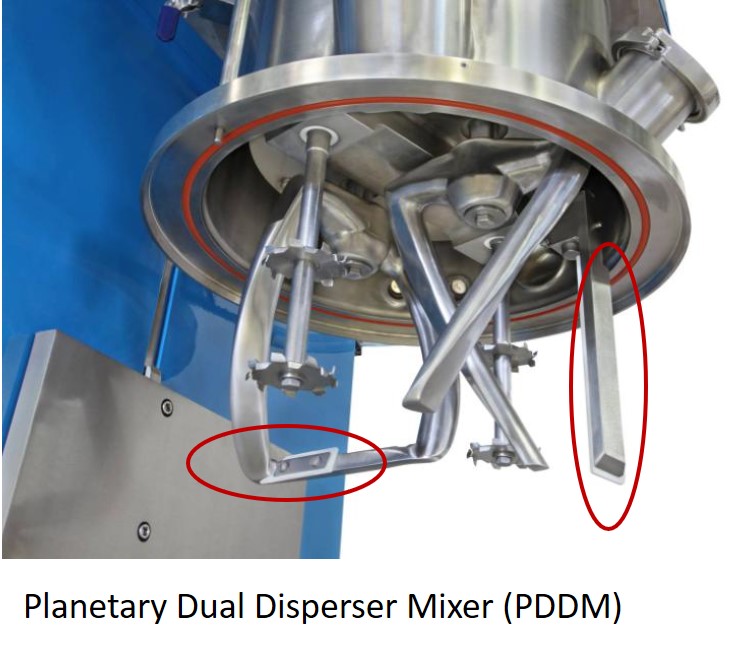

In the following figures, photos of multi-shaft mixers equipped with scraper blades are shown (all from Charles Ross & Son Company [1]).

I have used the PDDM for dispersing high filler loadings into many types of thermoset resins including dispersing fumed silica for rheology control. In my experience, scraper blades were not required in the PDDM equipped with helical blades, but they are available as on option as seen in the photo above. When I used dual-shaft and triple-shaft mixers, the addition of scraper blades was very beneficial in moving material into the cowles dispersion regions.

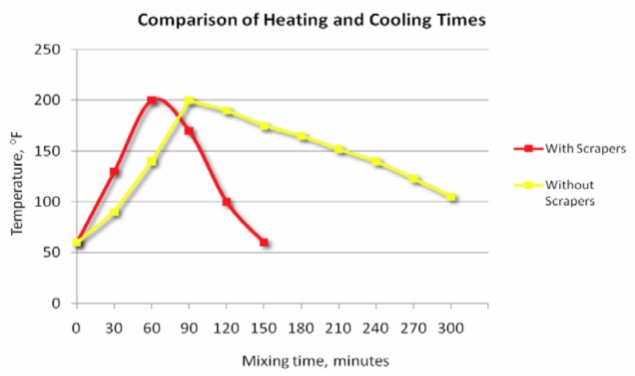

Figure 2. Scrapers improve heating and cooling rates. Source: Charles Ross & Son Company [1]

The addition of wall and bottom scrapers is very important in mixing processes that require a fast response to temperature changes. The graph above shows that using scrapers reduced the heating time of a gel material by approximately 33%, while the cooling cycle was reduced by approximately 60%. The larger improvement in cooling time can be explained by the tendency of most products to increase in viscosity when cooled and the materials near the jacketed sidewalls get more viscous and in the absence of scrapers, further inhibit product circulation and heat exchange [1].

References

- Charles Ross & Son Company, Mixing Technology Insight #29

Hi. This article was very useful for me. Can I ask you some questions in this field? thank you

Thank you for talking about how heat works within an acceptable range with mixing. I am starting an industrial business this year and getting my equipment prepared. I will find a great double planetary mixer in the area.