Guest Post by Dr. Robert (Bob) Humphreys

In two previous posts, we presented a brief overview of technological advances that have made automated sorting and recycle of municipal waste economically practical. Indeed, the range of sorted materials with significant economic value, such as paper, cardboard, glass, steel, aluminum, polyethylene terephthalate (PET) and high-density polyethylene (HDPE), is expanding to include low-density polyethylene (LDPE) and plastic film as advances and investment in technology continue and viable commercial outlets for these materials develop (see reference 1). So, the plastic recycling picture seems to be getting brighter.

Plastic recycling does not occur in a static environment. Market dynamics continue to present challenges that will need to be addressed effectively if plastic recycling is to continue to grow. In this post, we will use plastic food packaging to illustrate how changes in the markets served by plastic packaging technologies can complicate plastic recycling. In most cases, complexity increases cost, which does not help the recycling industry.

Barrier Materials and the Rise of Multi-layer Films

In the Introduction to this series about food plastic recycling (“Recycle and Disposal of Plastic Food Packaging Waste 1: Introduction”, Dec. 12, 2016), we provided a list of many, but by no means all, of the functions that plastic packaging serves. These functions change over time as consumer demands change. One example is the growing consumer preference for fresh, “natural”, and “preservative-free” foods. Preservatives and antioxidants serve a useful purpose in prepared foods and food manufacturers must compensate somehow for their absence. Similarly, increasing the shelf-life while maintaining the quality of fresh produce, meats, and fish can reduce costly waste in the distribution system.

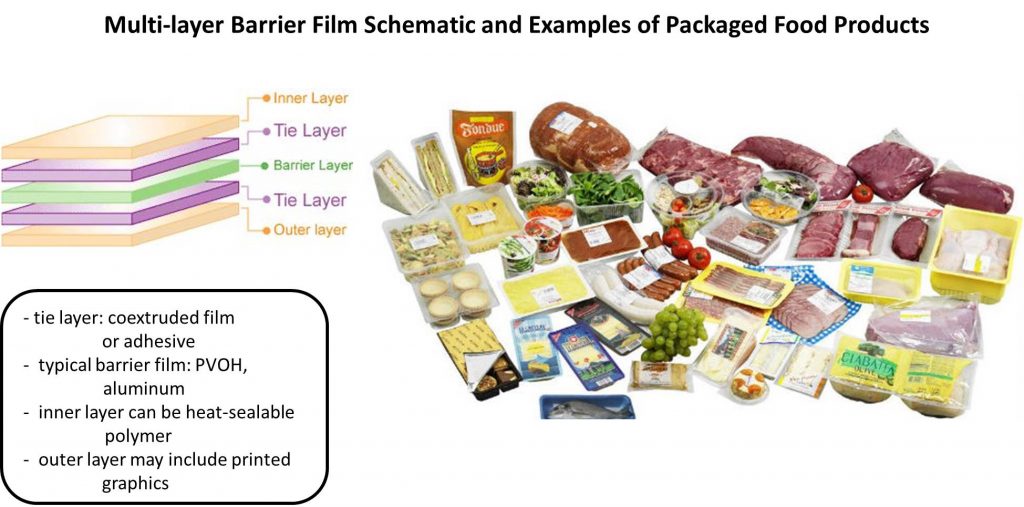

Multi-layer films (MLF) are one way food manufacturers can satisfy consumer desire for additive-free prepared and fresh/natural/organic foods while still delivering the quality discerning customers expect. Multi-layer plastic films can be complex structures with half-a-dozen or more layers, each with an important function. Layers can include aluminum film (when an impervious barrier to gases and moisture is mandatory), polymer with gas barrier properties (e.g. oxygen barrier, flavor barrier), “tie layers” of adhesive or polymers designed to bond different polymer films together when the polymers are not compatible, a heat-sealable polymer layer, a thicker base polymer layer that provides much of the strength and durability to the overall structure, and possibly an outer layer to accept graphics.

Adhesion between the films in multi-layer food packaging is usually exceeds film strength by a wide margin, making layer separation extremely difficult. Coupled with the huge variety in film types used in package construction and difficulty in designing automated separation equipment for complex layered film, MLF cannot be recycled economically. Methods are available for separation and analysis of MLF layers (reference 2) and approaches to design of recyclable MLF packaging have been published (e.g. reference 3). Nevertheless, market forces are growing the volume of multi-layer packaging waste in MSW and it is not apparent at this point in time if or when recycling will be feasible.

MSW Dynamics: Material Changes, “Light-weighting”, Energy Costs

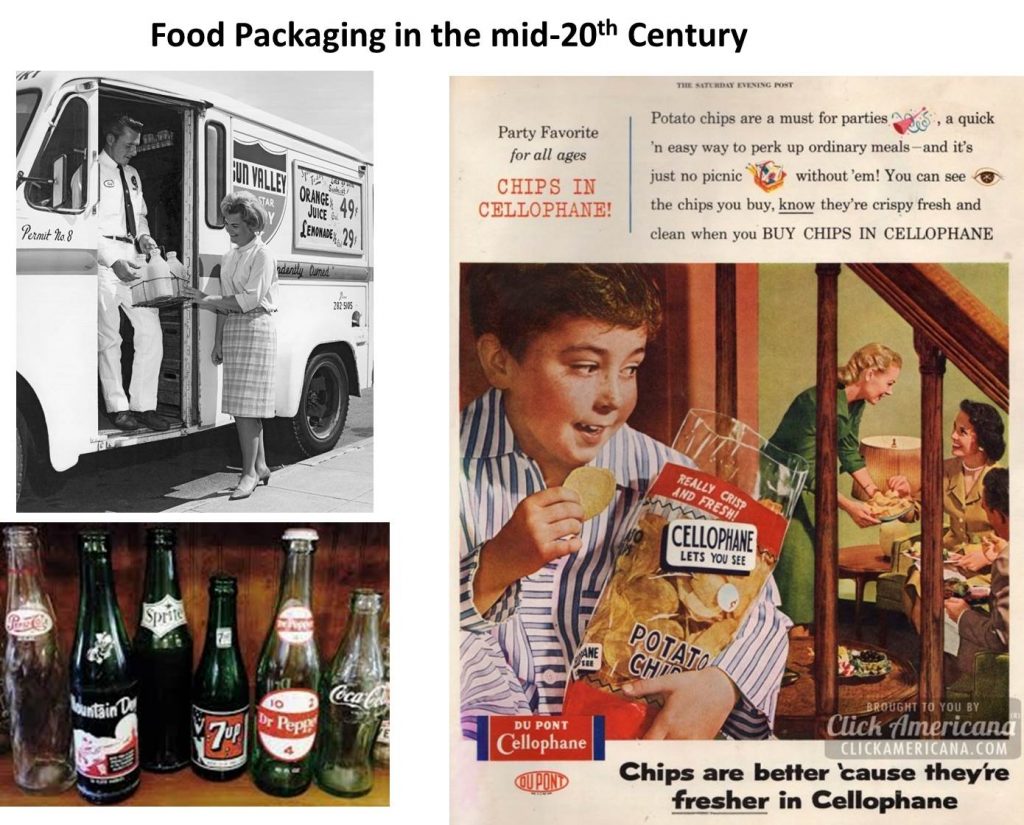

Baby boomers like yours truly remember when one departed from the grocery store with a cart containing soda in glass bottles, cereals kept fresh by wax-coated paper bags in boxes, and cellophane-wrapped lettuce, tomatoes and meat. Milk was delivered in glass bottles by the milk man and empties were returned to him the following week. Most homes had a newspaper delivered daily and magazines weekly or monthly. School lunch was a sandwich wrapped in wax paper and an apple in a brown paper bag. Most Generation Xers who have watched a Leave It to Beaver rerun in black-and-white (i.e. almost none of them) find it hard to believe such a time ever existed. On the other hand, if you are responsible for MSW disposition, the difference between then and now represents the kind of dynamic world in which you must do business. In fact, changes in MSW composition can change very rapidly compared to investment cycles for the large, capital intensive businesses associated with MSW disposal and recycling.

Page 31 of the 2014 “Sustainability Report” (see reference 4) from Waste Management, an MSW giant, provides a concise summary of many of the MSW material changes their business must face. For example, a precipitous drop in newspaper readership coupled with IT trends have changed the ratio of paper to containers in MSW from the 80/20 that MSWP facilities were designed to process to 60/40. Less newsprint in the paper stream results in less of a valuable recyclable material. Such trends can have a significant impact on recycling and overall MSW processing profitability.

Plastic packaging in MSW continues to grow, but again, trends can affect recycling profitability. For example, as we mentioned in the previous post, PET is the most valuable plastic recycle stream. However, inevitable pressure to reduce cost and advancement in technology have resulted in a 25-30% reduction in PET use per bottle (i.e. bottle walls are thinner), which has resulted in a reduction in the weight of PET recycle stream even as the number of bottles has grown. For an MSW processor and recycler, the same amount of labor and energy consumption is required to sort less of a high-value salable product. Obviously, economics are adversely affected.

Energy costs also complicate longer-term planning for MSW disposition and the recycling industry. The recent downward trajectory of petroleum pricing from $100+/bbl to under $50/bbl is good for MSW transportation and MSWP facility operating energy costs; at the same time, lower petroleum-based raw material prices reduces the cost of virgin plastic which competes with PET and HDPE recycle streams, putting downward pressure on recycled plastic prices (and profit). Lower costs for petroleum-based plastic raw materials also make renewable and compostable plastics less competitive economically. Coupled with relentless cost reduction in food manufacturing, switching from petroleum-based to renewable and compostable plastic packaging can be difficult to justify in a world of low and, perhaps worse, wildly unpredictable crude oil pricing.

Prospects for Plastic Recycling and Renewable/Compostable Plastics

There seems to be a general consensus that reduction in landfill use, recycling of waste materials, and reduction in MSW are good for society as a whole. Single-stream recyclable collection is becoming the norm throughout the USA and public support for it is generally strong. The same can be said for concepts such as increased use of renewable plastics and advances in composting and compostable plastics, although actual progress on both is nascent. On the other hand, consumer behavior plays a major role in recycling, particularly in single-stream recycling; MSW and recycling processors continually fight against a trend towards more non-recyclables content in recycle streams, including single-stream recycle, which raises operational costs. For businesses and municipalities trying to plan for investment in MSW processing and recycling facilities, such a dynamic environment requires caution, a drive for flexibility in facility design to respond to trends that change waste composition, and a continual effort to educate the public about their behavior since, in the final analysis, they pay the price for MSW disposition one way or another.

References

- See Plastics Recycling Update under News, March 9, 2017

- Guidance for the identification of polymers in multilayer films used in food contact materials

- Recycling of laminated packaging

- Creating a circular economy: sustainability report 2014.

I’ve always been concerned about the usage of plastic packaging. It’s nice to know that it can be recycled so well! If it’s properly recycled, I bet that plastic packaging could be just as healthy for the environment as any other material.