Guest post by Jeremy Pasatta, Advanced Polymer Coatings

The previous two blog posts have looked at both the fundamentals of toughening thermosets as well as one of the most common technologies used to toughen thermosets – Reactive Liquid Polymers and CTBN. In this blog post, we’ll look at toughening thermosets with coreshell particles.

Coreshell particles are exactly as the name implies, particles that contain a low modulus, low Tg core that is incompatible with the matrix resin, and to solubilize the particles within thermoset, a thin shell that is matrix compatible is placed on the outside of the particle. Typical examples of core chemistry include:

- Polysiloxane

- Polybutadiene

- Low Tg polyacrylates (butyl acrylate, 2-ethylhexyl acrylate)

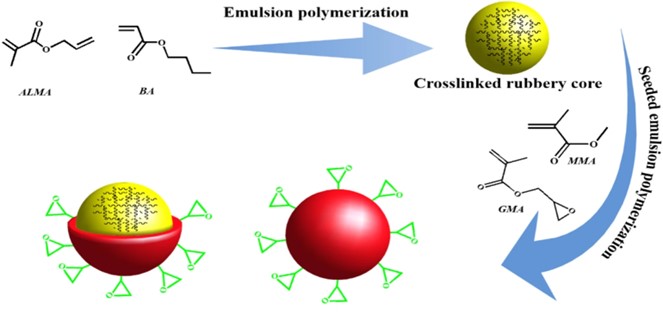

Similar to CTBN chemistry, the core of the particles consists of a low Tg polymer in order to facilitate particle cavitation ahead of the crack tip, which then allows for void dilation and enhanced plastic deformation of the matrix. Low Tg cores also allow for better toughening at low temperatures for applications like automotive structural adhesives. Typical examples of shell chemistries include copolymers of polymethylmethacrylate and glycidyl methacrylate, which introduces epoxy functionality onto the shell and allows for enhanced bonding with the matrix resin. These particles are commonly produced through emulsion polymerization, and a generalized synthetic overview is shown in Figure 1.

Figure 1. Production Method of Coreshell Particles [1].

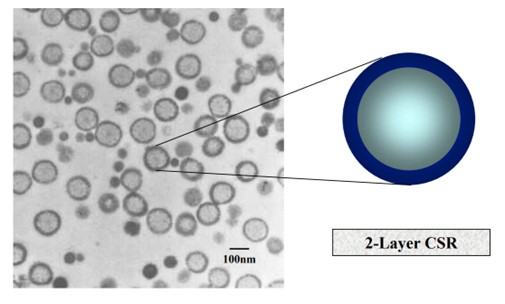

Coreshell particles are typically in the size range of 100-250 nm, which is the optimal size for toughening by this type of chemistry. The particles are typically very uniform in their size distribution, and after emulsion polymerization, they can either be isolated as solid coreshell particles which are then supplied to formulators for dispersion in their matrix resin, or predispersed at concentrations of 25-40% in typical thermosets such as epoxy. Figure 2 shows an SEM of coreshell particles dispersed in an epoxy resin.

Figure 2. SEM of Coreshell Particles Dispersed in Epoxy [2].

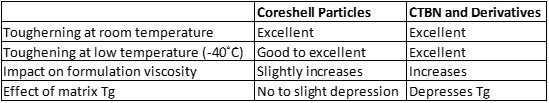

Since these particles are preformed and do not rely on Reaction Induced Phase Separation similar to RLP and CTBN, coreshell particles in general tend to give less matrix Tg depression because there is no polymer that does not phase separate and remains dissolved in the matrix, although some Tg depression is seen. Table 1 gives a generalized overall comparison of the performance of coreshell particles compared to CTBN in thermoset resins.

Table 1. Comparison of Coreshell Resins to CTBN in Toughening Thermosets

Because coreshell particles are preformed, they can be introduced in their neat form into any thermoset matrix so long as the shell is compatible with the resin, although this does require some shear to achieve a uniform dispersion. If the shell is not compatible with the matrix resin, the particles will agglomerate and will not form a stable uniform dispersion within the matrix resin. Applications for coreshell resins tend to be the same as those for CTBN polymers: structural adhesives, coatings, composites and electrical potting and encapsulation. Because coreshell particles tend to have less depression on the matrix Tg, they are more often used in applications such as high Tg aerospace composites compared to CTBN and their derivatives. Typical use levels of coreshell particles are 5-15 parts of coreshell for 100 parts of matrix resin. Above 15 parts coreshell resin there is little additional improvement in toughness on the thermoset.

Now that we have looked at the two most common forms of toughening (CTBN and their derivatives and coreshell particles) along with how these tougheners work, in the next series of posts we will look at some other forms of toughening thermosets, including block copolymers and hard particles, and how toughening technologies are often combined to achieve optimal and sometimes synergistic results.

References

- Scientific Reports volume 11, Article number: 20789 (2021)

- Kaneka Coreshell Toughening of Thermosetting Resins – Douglas J. Sober

Leave a Reply