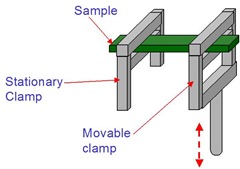

In our last post we discussed the various experimental details for a dynamic mechanical analysis. This post will cover the application of DMA to investigate the glass transition temperature (Tg) as well as measure the dynamic moduli as a function of temperature. DMA is particularly useful for characterizing thermosets since information on both the Tg and mechanical properties can be obtained in a single experiment.

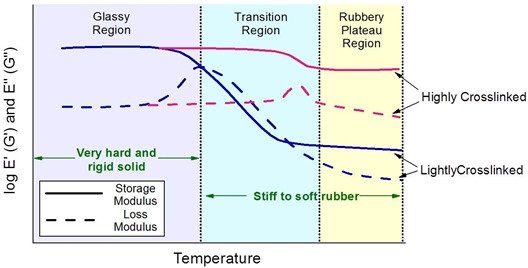

Thermosets can have different properties depending on the crosslink densities. The figure below depicts the effects of crosslinking on the various regions of the DMA curve. In the glassy region one observes that both the storage and loss moduli are independent of the degree of crosslinking. The effects of crosslinking are clearly observed in the glass transition region as well as the rubbery plateau region. One observes the lower crosslinked thermoset has a lower Tg and the storage moduli begins to decrease at much lower temperature. Also in the transition region, the loss modulus peak occurs at a lower temperature for the lightly crosslinked thermoset. The major difference may be observed in the dynamic moduli in the rubbery plateau region. The highly crosslinked thermoset has a much larger storage and loss moduli indicating the tighter network structure and higher stiffness.

Some characteristics of the glass transition temperature

- Transition of glassy solid to liquid or rubber in amorphous

material - 10 – 1000x decrease in storage modulus

- Tg = maximum in loss modulus or tan delta

- Frequency dependent transition with the Tg changing about 5 – 6°C per

decade

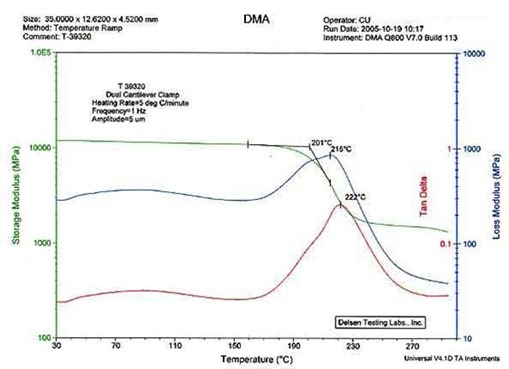

Let’s look at an example of how DMA can be used to measure Tg and reveal some subtle features in the morphology. In the following figure a DMA curve is presented for a phase separated thermoset.

One observes the storage modulus decreases in the vicinity of 200oC and there is a broad peak in both the loss modulus and tan delta. From the E”max, the Tg is 215oC and 222oC from the maximum in tan delta.

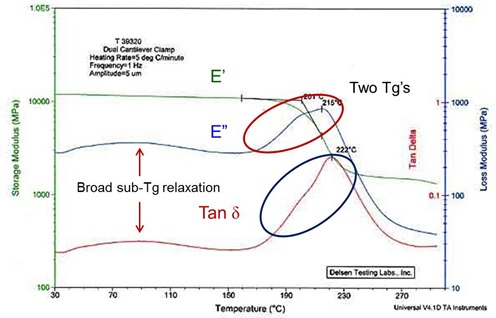

So lets take a closer look at what some of the subtle details may indicate.

Examination of the loss modulus peak shows that there is a shoulder on the low temperature side and a broad sub-Tg relaxation. A common way to toughen a thermoset is to use a low Tg rubbery second phase such as a CTBN rubber or a thermoplastic. During curing, the thermoset and the rubber will phase separate leading to a two-phase system. DMA provides a convenient probe to look macroscopically at phase separation. If the two materials have dissimilar Tg’s, then one can observe either two peaks or a shoulder on the loss modulus or tan delta curves if the Tg’s are close. Additionally, a rubbery material or low molecular weight thermoplastic will have segmental mobility in the separated phase so the broad sub Tg relaxation peak in the loss modulus and tan delta would suggest this. Further characterization would be required, such as optical or electron microscopy to examine fracture surfaces to more definitively characterize two phase systems. Nevertheless, DMA gives you a quick and easy first look into phase separation.

In our next post we will describe additional applications of DMA in the characterization of thermoset polymers.

why the glass transition temperature obtained from tan delta peak is higher than loss modulus peak

Pradeep,

Thanks for reading my blog and asking a question. Tan delta = E”/E’. In the glass transition region, E’ is dropping rapidly and E” is going thru a peak (at about the midpoint of the transition region). The result of the calculation is a peak in tan delta that is higher than the loss modulus. Another way to look at tan delta is that it represents the high end of the glass transition region. Tg is often thought of as a point, but in reality it is a range. See the width of the E’ and E” transitions. The initial drop in E’ is typically the start of the Tg region and the tan delta max is at the high temperature end of the Tg region.

Dear Jeffrey,

does loss tangent decides the rubber has isolation or damping characteristic. Give some insights on damping, isolation related to loss modulus.

Dear Jeffrey,

the idea to evaluate the difference between G’ and G” is very interesting. Is there any relevant literature who deals with the topic? I unfortunately have not found anything yet.

Thanks for help!