I just recently came across yet another article on how Six Sigma “killed” innovation at 3M (1). A prominent business magazine ran a cover story on the same topic. But guess what? Sensational headlines grab readers attention, but what really “killed” innovation (even that’s debatable, 3M seems to be doing pretty well these days) was the inappropriate application of Six Sigma by management. Six Sigma is a process and toolset that when applied properly can result in significant improvements and cost savings. The key here is that Six Sigma is not a one-size-fits-all approach and from the 3M press, it appears that it was not deployed properly in the R&D setting. Let me explain a little further.

I just recently came across yet another article on how Six Sigma “killed” innovation at 3M (1). A prominent business magazine ran a cover story on the same topic. But guess what? Sensational headlines grab readers attention, but what really “killed” innovation (even that’s debatable, 3M seems to be doing pretty well these days) was the inappropriate application of Six Sigma by management. Six Sigma is a process and toolset that when applied properly can result in significant improvements and cost savings. The key here is that Six Sigma is not a one-size-fits-all approach and from the 3M press, it appears that it was not deployed properly in the R&D setting. Let me explain a little further.

First let’s define innovation, so we are on the same page. Innovation is the successful commercialization of inventions, new ideas, business models, etc. In my definition, innovation encompasses everything from the creative process to formulate a new concept (research & applied research for products), market development, product development, scale-up, and product launch. Successful innovation requires two components:

- Creativity

- Productivity

Herein lies the problem. Creativity and productivity can be polar opposites! Six Sigma is a productivity tool. There is a mountain of literature of success stories where companies have successfully used Six Sigma to optimize manufacturing, reduce defects, and save a ton of money. There is also a solid body of work demonstrating how Six Sigma can be effectively utilized in the product development process (where productivity is an important factor, especially with complex products on a tight commercialization timeline).

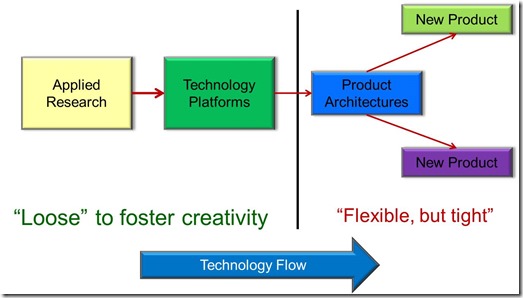

The absolute wrong place to use Six Sigma is in the creative process. I have experience implementing Design for Six Sigma in multiple companies and at no time did we even think about using Six Sigma in the research and applied research phases. I like to think of the technology delivery process as “loose – tight”:

Once you have market needs or in the case of semiconductors, a technology roadmap, the innovation process starts in the lab with focused applied research to develop technology platforms. Here there will be many ideas considered, experiments that fail (opportunity to learn), and multiple iterations. The creativity of your researchers cannot be hindered. Give them a solid target and get out of the way! Most of the time, the bigger or more challenging the target, the more the scientists get jazzed. Six Sigma in this part of the process will not foster the inquisitive thinking, experimentation, and the inevitable failures that are all part of research. Remember, failure is an opportunity to learn. Engineers and scientists have used this for centuries (The Romans were great engineers, but they didn’t have CAD design programs back then, so they used a lot of trial and error learning cycles to build some amazing structures).

The key to successful Design for Six Sigma (DFSS) implementation is to know when and how to leverage the Six Sigma toolbox.

References

1) https://www.zdnet.com/six-sigma-killed-innovation-in-3m-7000012593/

Leave a Reply