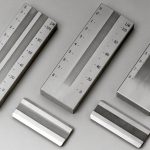

Previous nine posts covered many of the mechanical aspects of dispersing fillers into thermoset resins. The final post in this series will cover measuring the mixing effectiveness using the fineness of grind or the Hegman gage. The Hegman gage is commonly used as a quality control test at the end of a mixing process. A small amount of material is required and can be obtained ... [Click to Continue...]

Dispersion of Highly Filled Thermosets – Part Nine: Efficacy of Sweeper Blades During Mixing

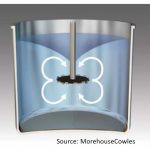

Previous posts have covered the various types of mixing geometries such as single, dual and triple shaft mixers and double planetary mixers. The focus was on understanding the mixing physics. There are several ways to improve the efficacy of the mixing process. The last post covered the use of vacuum to accelerate degassing during the mixing process. This post will discuss ... [Click to Continue...]

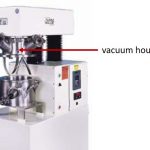

Dispersion of Highly Filled Thermosets – Part Eight: Vacuum Degassing

The previous posts have focused on the mechanics of the mixing process and have briefly covered the use of vacuum during mixing. This post will discuss vacuum degassing in detail. Many commercially important, highly-filled formulations require effective vacuum mixing to achieve the desired properties. Many liquid or viscous thermoset resins need to be degassed prior to ... [Click to Continue...]

Dispersion of Highly Filled Thermosets – Part Seven: Dual Axis Centrifugal Laboratory Mixers

The first six posts in this series covered the various types of equipment used to disperse fillers into uncured thermoset resins. The information was applicable to all sizes of mixing equipment. This post will focus on laboratory size mixers for use during formulation development and testing. In the formulation phase, multiple iterations are typically required to optimize ... [Click to Continue...]

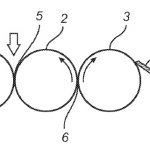

To Mix or Mill: Thick Film Paste and Ink

Guest Post by Ken Kuang, Torrey Hills Technologies Introduction Thick Film Material is an ink paste produced through dispersing metal powders, glass powders, and inorganic oxides with organic solvent in a three-roll mill. The thick film pastes are screen-printed on ceramic boards or green sheets as circuit patterns and then fired at high temperatures. The thick film ... [Click to Continue...]