At the recent Bioplastics: The Reinvention of Plastics conference in Las Vegas, March 4-6, 2013 there were 25 papers, 21 exhibitors, talking about their recent advances in biopolymers and bioplastics. There was one consistent theme echoed over the last couple years. Bioplastics are increasingly finding interesting applications in durables. Initially, a lot of industry buzz was centered on biodegradable polymers, but unfortunately the collection and composting infrastructures are not readily available in most locales. The focus in the last several years has been the development of bio-based polymers and bio-based compounded plastics for use in durable applications.

At the recent Bioplastics: The Reinvention of Plastics conference in Las Vegas, March 4-6, 2013 there were 25 papers, 21 exhibitors, talking about their recent advances in biopolymers and bioplastics. There was one consistent theme echoed over the last couple years. Bioplastics are increasingly finding interesting applications in durables. Initially, a lot of industry buzz was centered on biodegradable polymers, but unfortunately the collection and composting infrastructures are not readily available in most locales. The focus in the last several years has been the development of bio-based polymers and bio-based compounded plastics for use in durable applications.

Some of the durable applications presented at the conference were:

- NatureWorks impact modified plexiglass RnewTM biopolymer alloys

- Green polyethylene terephthalate (PET) being driven by Coco-Cola for beverage containers

- Bio-based polyamides (nylons) from Cathay Industrial Biotech and Verdezyne, USA

- Bio-based polyamides (PA610) from Toray Industries

- Computer enclosures and sound attenuation foams from IBM

- Oven pan liners from bio-based copolyester elastomers

- Bio-polymer coated paper and cardboard packaging

Here are two examples of bio-based polymers being developed for durable applications.

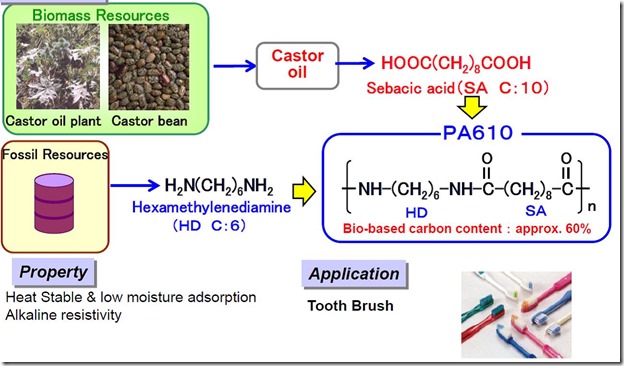

Bio-based Monomer Replacement

The best example of this is the PlantBottleTM from Coca-Cola where the monoethylene glycol (MEG) component is made from non-fossil fuel starting materials. At the Bioplastics conference, Toray discussed their approach to a bio-based polyamide. Analogous to the bio-PET approach, Toray utilizes castor oil plants and castor beans as the raw material source of castor oil which in turn yields sebacic acid. The hexamethylenediamine is sourced from fossil fuel and when polymerized with sebacic acid forms PA 610 with an approximate bio-based carbon content of 60%, This route provides a pathway to reduce carbon footprint and decrease the reliance on fossil fuel resources. The synthetic pathway is summarized in the following figure:

Source: Toray Industries, Japan presentation at Bioplastics, Las Vegas, March 2013

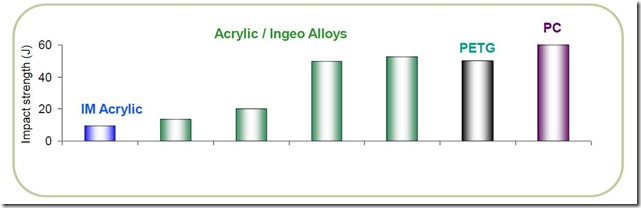

Use of Bio-based Polymers in Alloys

NatureWorks, LLC the manufacturer of polylactic acid (PLA) presented an approach to enhance the impact strength of acrylics using PLA as an alloy. See our posts in the September 2012 archives for more details on PLA. In acrylic blends with Ingeo PLA, the impact strength can be improved in a systematic manner depending on the PLA content. The PLA alloys trade named Plexiglass RnewTM have excellent optical properties being transparent, high gloss, and easily accept colors making it versatile to designers. The impact improvements over the composition range are shown in the next figure:

Source: NatureWorks, LLC presentation at Bioplastics, Las Vegas, March 2013

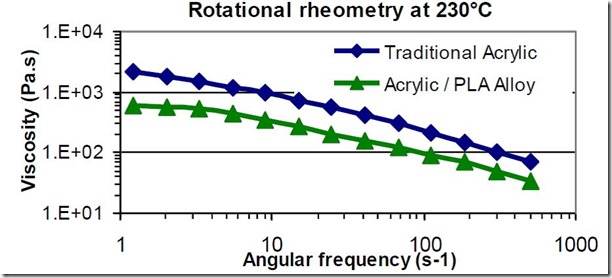

The formulation design allows for tailored solutions while improving the impact resistance while maintaining modulus and strength. An added advantage of the PLA alloy approach is an unexpected improvement in the melt processing characteristics. The PLA/acrylic allows also have increased service temperature compared to pure PLA. The viscosity- frequency plot shows the acrylic/PLA alloy has a lower viscosity compared with a traditional acrylic over a wide frequency (ie. shear rate) range as shown in the following graph:

Source: NatureWorks, LLC presentation at Bioplastics, Las Vegas, March 2013

There were many other examples of modifying traditional fossil fuel based polymers with bio-based polymers and additives to to improve both the environmental impact and improve the product properties.

Our next post will cover polyhydroxyl alkanoate (PHA) authored by Dr. Robert Humphreys.

Leave a Reply