Guest Post by Jeremy Pasatta, Advanced Polymer Coatings

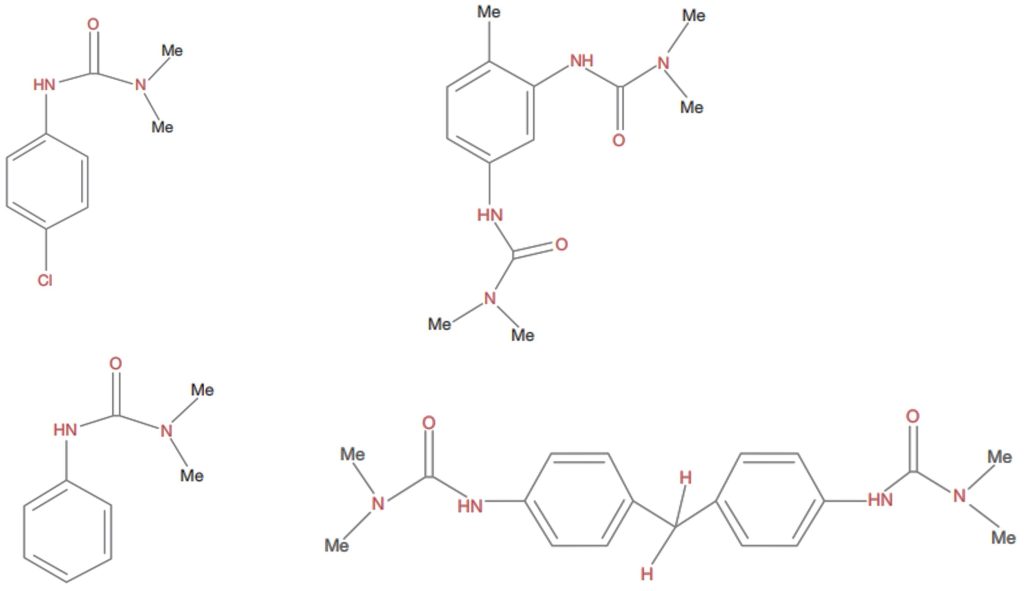

Latent curing agents for epoxy resins allow for the creation of stable one component formulations used in adhesives and composites that have outstanding high temperature and mechanical properties. In order to activate the latent curing agents, heat is required to initiate the reaction. Industrial processes however are continuously being optimized, with the heat required to cure being lowered and the time to cure being shortened in order to keep the overall cycle time low. Therefore latent curing agents for epoxy, such as dicyandiamide, also make use of an accelerator to lower the cure time and temperature. The most used accelerator for dicyandiamide is a urea-based structure. Common structures of urea accelerators are shown in Figure 1. The urea portion of the structure is highlighted in red.

Figure 1. Common urea accelerator structures

The substitution on the urea group can affect the following properties of the epoxy formulation:

- Speed of cure

- Temperature of cure

- Latency, or shelf life, of the one component formulation

- Final properties of the cured epoxy, in particular Tg

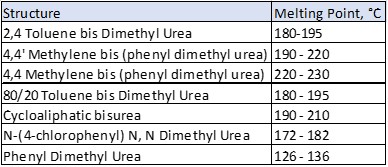

Table 1 gives some of the more common commercially available urea structures along with their melting points. The fact that the melting points if the urea accelerators are higher than typical cure temperatures means that the accelerators will only be dispersed in the formulation and are not soluble of will not melt into the formulation.

Table 1. Common commercially available urea structures

It can be noted that in Table 1, there are two different entries for 4,4’ methylene bis (phenyl dimethyl urea) with slightly different melting points. Depending on the starting raw materials and synthesis conditions, the final product can vary slightly and can give a different reactivity and stability profile. When formulating a one component epoxy formulation using dicyandiamide and urea accelerators, a typical formulation would contain the following:

- 100 parts epoxy resin

- 5-8 parts dicyandiamide

- 1-5 parts of urea accelerator

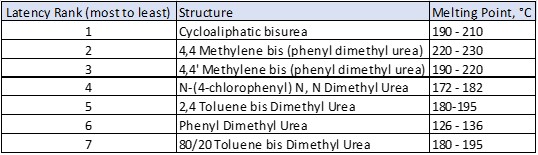

Dicyandiamide without accelerators requires heat to about 180˚C to achieve curing, usually in a period of 30 to 40 minutes. By incorporating urea accelerators, the curing temperature can be lowered to 120 to 150˚C and can cure in less than 30 minutes, saving the formulator time and money in curing final parts, which is particularly important for automotive OEMs using one component epoxy adhesive. In general, the more the urea accelerator decreases the curing time and temperature, the less stable the one component formulation. Shelf life for extremely active urea accelerators can range from 4 to 8 weeks, where less reactive urea accelerators can give one component epoxy formulations that have shelf lives greater than one year. The shelf life of these formulations is typically measured as the time required to double in viscosity. Table 2 gives a ranking of the stability of a one component formulation containing urea accelerators, with the first being the most stable.

Table 2. Latency of Urea Accelerators, Most Stable to Least Stable

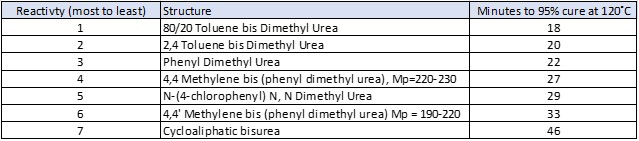

As stated previously, the least latent urea accelerators tend to give the largest decrease in cure time and temperature. Table 3 gives a ranking of the urea accelerators in terms of their reactivity, measured as the time to reach 95 percent cure at 120˚C, measured by DSC.

Table 3. Reactivity of Urea Accelerators, Most Reactive to Least Reactive

Comparing Table 2 and 3, the most reactive urea gives the least shelf stable formulation, and the least reactive urea gives the most shelf stable formulation. One interesting note on the comparison of Tables 2 and 3 is the 4,4’ methylene bis(phenyl dimethyl urea) with melting point of 220 to 230˚C is the second most stable of all of the urea structures, and also has the fourth highest reactivity. This is a unique structure that gives a very good balance of reactivity and stability, making it a popular choice in stable one component formulations.

The correct choice of accelerators in latent, dicyandiamde cured epoxy formulations leads to a significant reduction in curing time and temperature while still maintaining a formulation that is stable enough to be used in a reasonable time frame. Latent epoxy formulations are not the only type of formulations that commonly use accelerators. In the next blog posts, accelerators for amine and anhydride cured epoxies will be discussed.

Leave a Reply