In our last post, the experimental methods for measuring the rheological changes to UV exposure were presented. This post will discuss the impact of UV exposure on the rheological properties such as the dynamic loss and storage moduli. The thickness of the sample is important in UV curing. If the sample is too thick, depending on the polymer/initiator combination, the UV radiation may be retarded from reaching the bottom of the sample leading to incomplete curing. In this post we will present data from the TA Instruments Application Notes AAN021, Rheological Studies of UV Curable Materials.

In our last post, the experimental methods for measuring the rheological changes to UV exposure were presented. This post will discuss the impact of UV exposure on the rheological properties such as the dynamic loss and storage moduli. The thickness of the sample is important in UV curing. If the sample is too thick, depending on the polymer/initiator combination, the UV radiation may be retarded from reaching the bottom of the sample leading to incomplete curing. In this post we will present data from the TA Instruments Application Notes AAN021, Rheological Studies of UV Curable Materials.

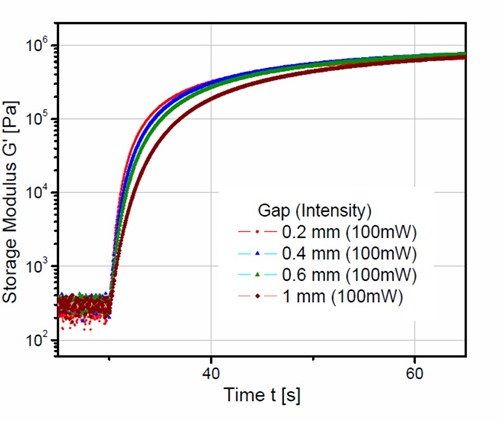

To investigate the impact of the gap height, a series of runs were made using gap heights from 0.2 mm to 1.0 mm in the parallel plate geometry for an acrylate-based pressure sensitive adhesive (1). From measurements of the initial reaction rate and the final complex modulus, a gap of 0.6 mm was found to be optimal. In Figure 1, the storage modulus (G’) is plotted as a function of time for various sample gap heights. The UV intensity was held constant at 100mW.

Figure Courtesy of TA Instruments

Figure Courtesy of TA Instruments

Figure 1. The dynamic storage moduli plotted as a function of time to demonstrate the effect of sample gap height on the UV curing reaction.

In all of the following experiments, the baseline was established for the unexposed material and then the shutter was opened to allow the UV light to be projected into the parallel plate geometry. In all cases, as typical for UV curing, there is a very rapid increase in the storage modulus indicating rapid polymerization. One of the benefits of using UV radiation to cure thermosets is the ability to achieve very fast curing kinetics. In Figure 1, the largest gap height leads to slower reaction rates. There are small differences in the initial reaction rates for the 0.2, 0.4, and 0.6mm gap heights, but once the time reaches approximately 40 seconds, the storage moduli are nearly the same independent of gap height.

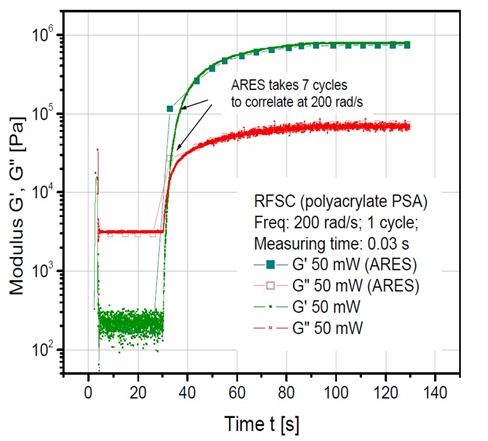

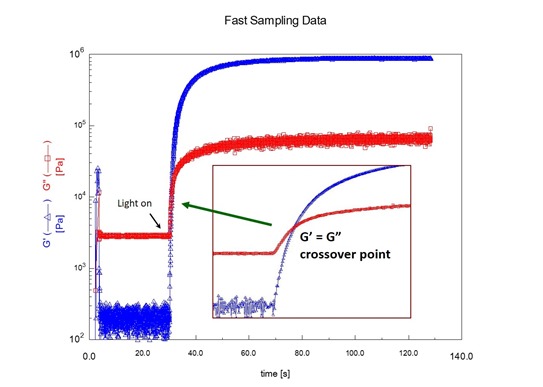

In our posts on the rheology of thermosets during curing, we demonstrated that the G’=G” crossover point is an approximate measure of the gel point. Remember that the gel point is an important parameter in the processing of thermosets, including UV curable thermosets. The gel point represents the formation of the equilibrium modulus along with a very high viscosity. For practical purposes, the gel point is essentially the end of the flow window during processing. In Figure 2, the dynamic moduli storage modulus, G’ and the dynamic loss modulus, G” are plotted as a function of time.

Figure Courtesy of TA Instruments

Figure Courtesy of TA Instruments

Figure 2. Dynamic Moduli, G’ and G” plotted as a function of time for a 50mW UV exposure.

In Figure 2 one notes that UV exposure causes a very rapid reaction rate and the dynamic moduli G’ and G” exhibit a crossover very quickly (on the order of a few second after UV exposure). The square data points in the G’ curve were data taken using the standard rheometer data acquisition speed (labeled ARES in the graph). The continuous data in the figure was obtained using the very fast data acquisition software develop for UV curing in the rheometer. Expanding the time axis in the above figure may be seen in Figure 3.

Figure Courtesy of TA Instruments

Figure Courtesy of TA Instruments

Figure 3. Dynamic Moduli, G’ and G” plotted as a function of time for a 50mW UV exposure.

Consistent with isothermal curing (such the curing of Five Minute Epoxy at room temperature), the crossover of the dynamic moduli G’ and G” can be clearly measured using the UV rheometer. Using the UV rheometer, one can characterize the curing rate and gelation during UV exposure. The effects of UV intensity and UV dosage on the curing kinetics and final cured properties such as the storage moduli can be measured.

In the next post we will discuss the impact of UV intensity and UV dosage on the rheological properties of the UV-curable acrylate pressure sensitive adhesive.

References:

1). TA Instruments Application Notes AAN021, Rheological Studies of UV Curable Materials

Leave a Reply