Guest Post by Dan Lamone

I am honored to have received an invitation to be a guest blogger here on the Polymer Innovation Blog. We will spend the next couple months discussing a favorite subject of mine – ultraviolet (UV) curing. A versatile toolset in the engineering toolbox, the photochemical reaction mechanism employed by UV curable resins provides development and manufacturing engineers alike with benefits impossible to find in traditional thermal-cure systems.

I am honored to have received an invitation to be a guest blogger here on the Polymer Innovation Blog. We will spend the next couple months discussing a favorite subject of mine – ultraviolet (UV) curing. A versatile toolset in the engineering toolbox, the photochemical reaction mechanism employed by UV curable resins provides development and manufacturing engineers alike with benefits impossible to find in traditional thermal-cure systems.

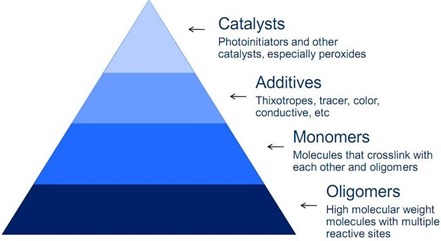

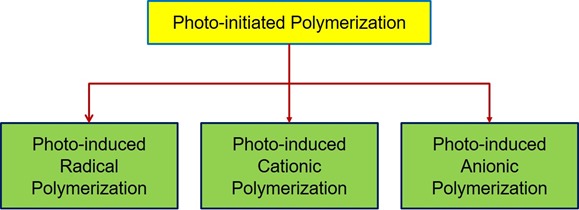

What is a UV curable resin? A 30,000-foot view is a resin system that employs a photoinitiator molecule to absorb ultraviolet radiation and utilize that energy to initiate the polymerization of a set of monomer(s) and/or oligomer(s). A schematic of a typical UV formulation is given in the image on the left. The monomers and oligomers are used to tailor the properties in both the uncured and final cured state. Additives such as thixotropic agents (rheology modifiers) may be added to aid processing. The photoinitiator molecule is the key to understanding the resin system’s capabilities and requirements. UV- curable resins are best classified by photoinitiator’s reaction mechanism with the two most common classes being free-radical and cationic/anionic. After that quick classification the description of UV-curable resins opens up in many directions, all based on the end use application.

Viscosities can range from water-thin at room temperature to that of traditional hot-melts. The resin systems can be filled or un-filled or pigmented (yes, pigmented). Resin functionality can vary from traditional mono-, di- and tri-functional monomers to hyper-branched oligomers with functionalities greater than 18! Resin glass transition temperature and physical performance can be further tuned as monomeric and oligomeric backbones can be of an aliphatic or aromatic nature or contain pre-polymerized constituents such as polyesters or polyurethanes. And just like solvent-based or thermal-cure systems, additive packages can be introduced to tailor specific performance. The list goes on, and on, and on.

Why consider UV curable resins? UV resins are single-component, cure on demand systems that will generally achieve full cure in under 60 seconds. Imagine a manufacturing environment free from solvents, energy-intensive ovens, long cure cycles, pot-life and two-component mixing constraints. Like all resin chemistries, limitations and constraints exist; however, the potential benefits that your organization may gain by employing UV-curable resins easily makes this discussion worthwhile.

I hope the technical insights in this series reach out to both experienced practitioners and UV-curing novices alike. Future posts will cover the following topics:

- Characteristics of the UV spectrum

- Photoinitiator absorption and polymerization mechanisms

- UV- Light sources, measurement, and irradiance calculations

- Traditional application best practices

- Hopefully, several advanced and hybrid technologies

In the next post we will consider the characteristics of the UV spectrum.

I had no idea UV resins were capable of achieving a full cure in under 60 seconds. This would really make production go so much faster with such an impressive cure time. I’ll have to look into a good monomers provider and look at my options.