The previous post described the chemistry and formulations using Recyclamine® hardeners. This post will discuss the process to chemically remove the cured network from the glass fabric reinforcement.

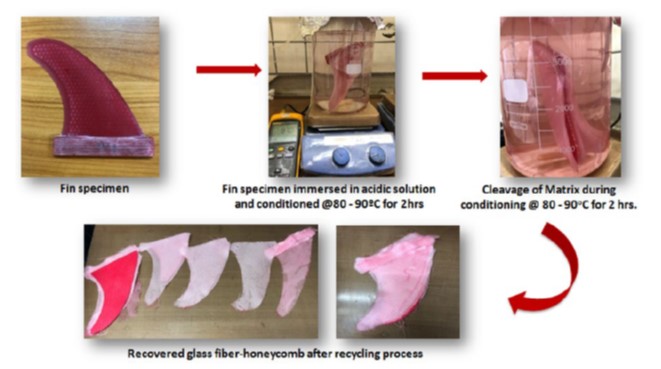

Dubey et. al., describes the details of a formulation specifically designed for wet lay-up resin transfer molding RTM [1]. The recyclable RTM formulation was used to produce glass fabric reinforced surfboard fins. A red pigmented RTM resin formulation was injected into the surfboard fin mold at room temperature. After curing, the composite fins were rinsed in an acetic acid solution at 80°C for 2 hours. The resin extraction process is shown in Figure 1.

Figure 1. Recycling process for composites containing Recyclamine® hardeners [1].

The resin extraction process consists of:

- Composite immersed in acetic acidic solution for 2 hours at 80-90°C.

- Cleave the linkage in the Recyclamine® hardeners.

- Recover both resin and fiber matrix.

Within 1 hour of immersion, the resin infused composite began to soften due to cleavage of the Recyclamine® hardener linkages. After two hours of immersion, the epoxy resin matrix completely cleaved and dissolved in the acetic acid solution [1].

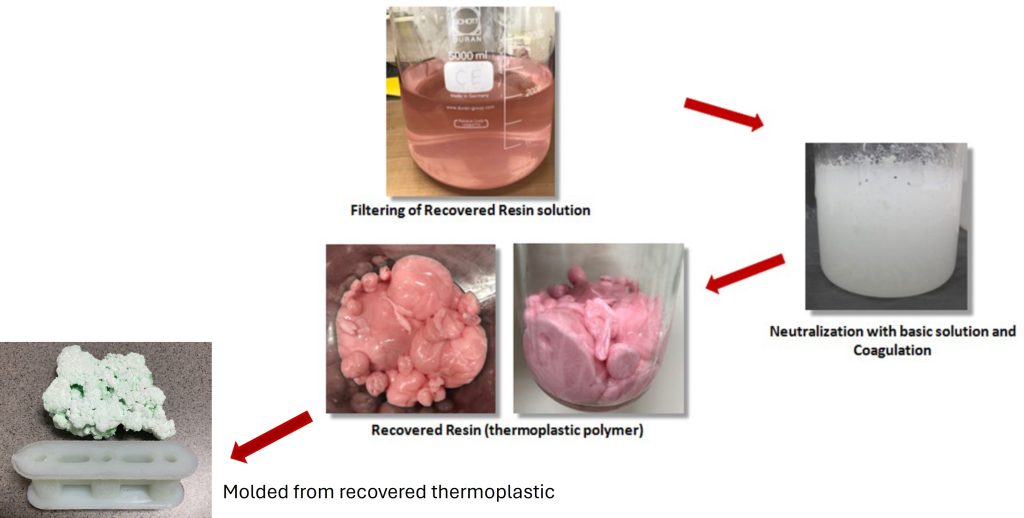

In the next step of the recycling process was to take the solution containing the dissolved epoxy resin matrix and separate from the glass fabric and filter. The reinforcement (glass fiber matrix) was dried and recovered for reuse. The cleaved epoxy matrix that was in the acetic acid solution was neutralized and coagulated resulting in a thermoplastic resin [1].

The resin recovery process is shown in Figure 2.

Figure 2. Recycling process to recover resin containing Recyclamine® hardeners after removal from carbon fiber or other types of fiber matrices [1].

After the recovered thermoplastic resin was dried, a test part was molded demonstrating the reuse of the recovered thermoplastic material. The recovered thermoplastic had a Tg of 67°C. The recovered thermoplastic was compounded with polyethylene in an 80:20 ratio and injection molded to form a foot strap insert for surfboards [1].

Resin systems incorporating cleavable linkages allow for recovery of resin and reinforcements:

- Recyclamine®

- Vitrimax (as discussed in a previous post in this series)

Large scale commercial use of vitrimers or utilization of resin chemistries with cleavable linkages is still in the early stages. The largest hurdle to overcome is how to scale to viable volumes and large composite part sizes. Resin recovery processes currently require high temperature solvent baths to solvate/dissolve thermoset resin networks. The focus of the current work utilizing cleavable linkages is to recover the high value-added carbon fibers.

References

- Dubey et. al., Recyclamine® – Novel Amine Building Blocks for a Sustainable World, SAMPE neXus Proceedings. Virtual Event, June 29 – July 1, (2021). Society for the Advancement of Material and Process Engineering – North America

Leave a Reply