This post is part one of a multiple part series on the topic of end-of-life considerations for thermosets. There is currently a lot of discussion in the press regarding recycling, ocean plastic, littering, and other considerations regarding how to handle plastics after their original use. This series will focus only on thermosets, which up until recently have been only considered for mechanical re-use (grinding and using as filler) and very limited chemical recycling. Let’s start the discussion on end-of-life for thermosets as shown in Figure 1.

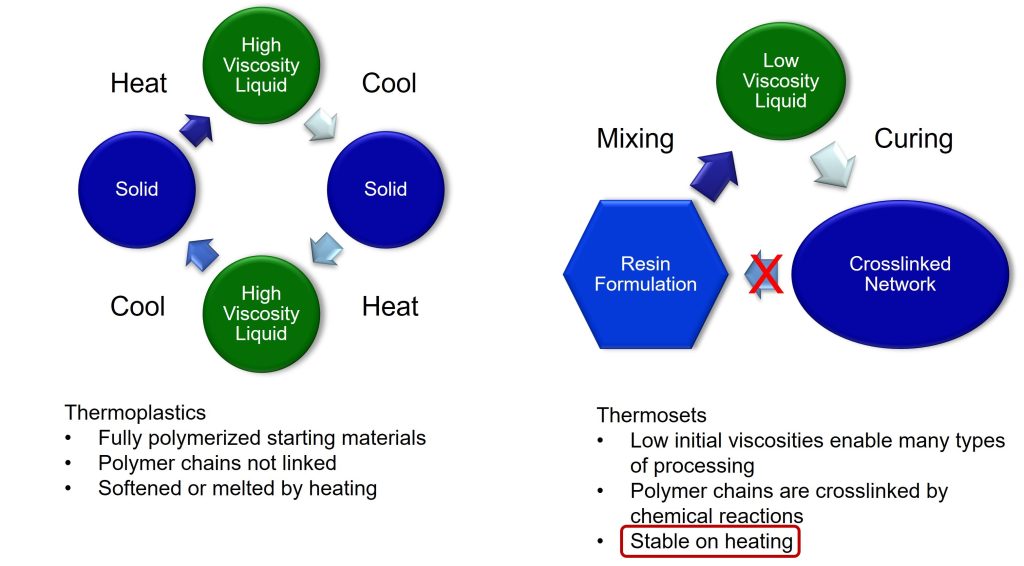

Figure 1. Thermoplastic processing versus Thermoset Processing

On the left side in Figure 1, recall that thermoplastics are fully polymerized long-chain molecules. Examples are polyethylene (PE), polypropylene (PP), and polystyrene (PS). For the purposes of this discussion, it does not matter if the thermoplastic polymer is crystalline (PE and PP) or amorphous (PS). Heating a thermoplastic polymer above its melting point (Tm) or glass transition temperature (Tg) causes the polymer to soften and flow. In the polymer melt state, processes such as extrusion, injection molding, compression molding, and blow molding make products we use every day. At the end of life for a thermoplastic, the material may be collected (recycled) and subsequently re-molded as before above Tm or Tg.

For thermosets as shown on the right side in Figure 1, a resin formulation typically consisting of a base resin (monomers or oligomers) and various additives such as hardeners, catalysts, fillers, flame retardants is mixed (compounded). The compounded formulation is then placed in a heated mold and is both shaped and chemical reactions result in a crosslinked network. The fully cured crosslinked networks are insoluble (due to the high crosslink density) and stable upon heating above the Tg. Thus, in the past, thermosets were hard to re-use or recycle. In Figure 2, there are several approaches for tackling the end-of-life challenge for thermosets.

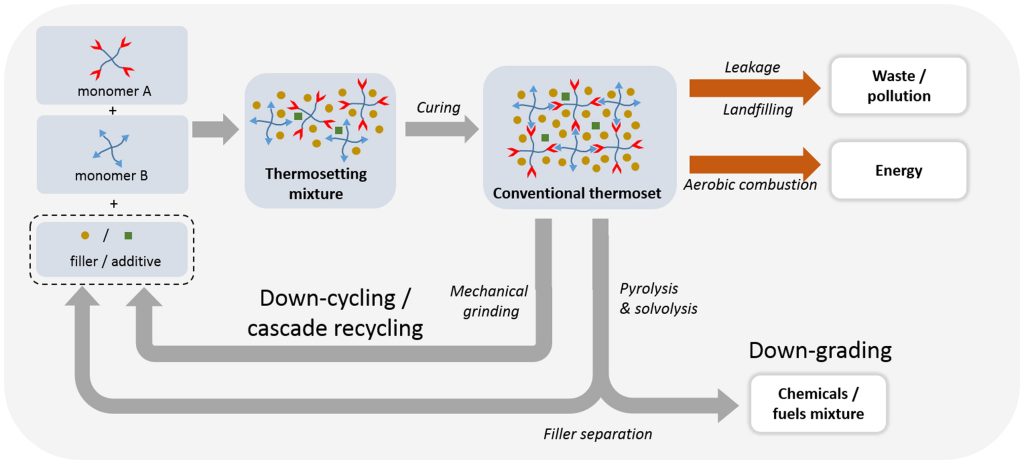

Figure 2. Multiple streams available for thermoset end-of-life. [1]

Figure 2 shows some of the routes that thermosets travel at the end of their use. First, since thermosets are hard to reuse, they are likely to end in the landfill as waste/pollution. Many readers have seen pictures of used wind turbine blades that have been decommissioned, cut into pieces and buried in landfills. Some thermosets are incinerated to produce energy. A common method is to take thermoset composites (with resin and filler) and mechanically grind them into small particles and use them as fillers in various types of products. There has been some new developments in the area of thermosets reuse over the last decade that will be covered in this blog series. Figure 3 shows a high-level view of the approach.

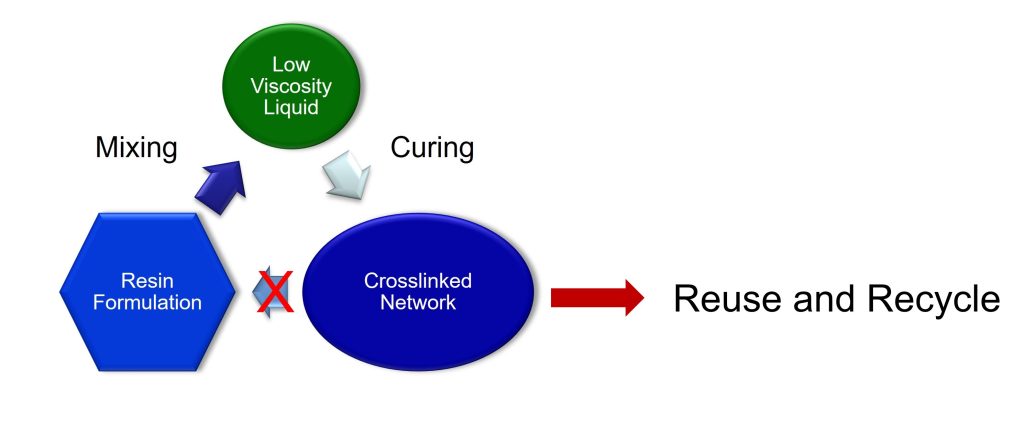

Figure 3. New Approach to Thermoset Recycling

Recent advances have enabled the “deconstruction” of cured thermoset networks using:

- Vitrimers (covalent adaptive networks)

- Dynamic covalent bonds

- Cleavable linkages in epoxy hardeners

The next several posts will cover the chemical pathways that are emerging to handle thermoset polymer waste. The main driver is to either re-use the filled thermoset composite (vitrimers) or chemically remove the cured thermoset network from the expensive fiber matrix (specifically carbon fiber matrices).

References

- POLYMER REVIEWS 2020, VOL. 60, NO. 2, 359-388 https://doi.org/10.1080/15583724.2019.1673406

Leave a Reply