Some thermoset polymers have useful properties in the as-cured condition. However, many thermosets are modified using fillers to achieve the desired properties. Fillers are used to:

- Lower coefficient of thermal expansion (CTE)

- Increase electrical conductivity

- Increase thermal conductivity

- Improve impact strength or fracture toughness

- Increase stiffness

- Reduce shrinkage

- Modify the rheological properties (flow)

In the next couple posts we will focus on the top three filler applications in thermosets. Typical thermosets used in adhesives, laminates, and composites are usually low viscosity liquids prior to curing. The low resin viscosity allows the addition of various types of fillers up to reasonable loading levels and maintain acceptable flow and processing. Many adhesives contain fillers to modify the rheological properties during dispensing. Fillers can take on many shapes and morphologies.

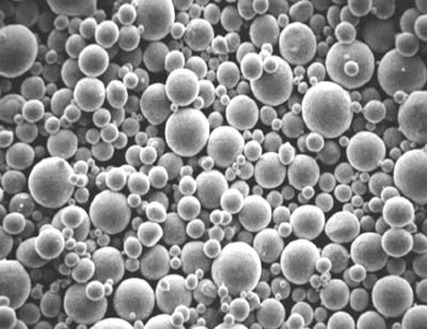

Typical fillers can be spherical, grain-like, plate-like, or rods. Additionally, fibers (both woven and non-woven) can be used to improve the fully cured mechanical properties. In the following two SEM images, a spherical silica powder is shown:

From the SEM image one notices the smooth and uniform spherical shapes typical of fused silica fillers. Spherical fillers can usually be added up to high volume percent before the viscosity increases too dramatically. In the SEM image above, note that the particle size is not uniform. Most fillers have a range or distribution of filler sizes. The filler suppliers can sieve or cut off the high particles if a more narrow distribution is necessary. For example, big particles may cause needle clogging during adhesive dispensing through a small needle.

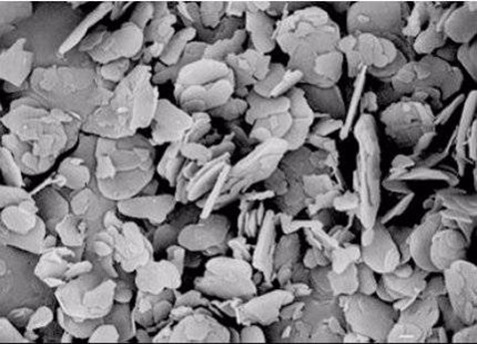

In the SEM image below, a boron nitride (BN) filler (used to enhance thermal conductivity) is shown:

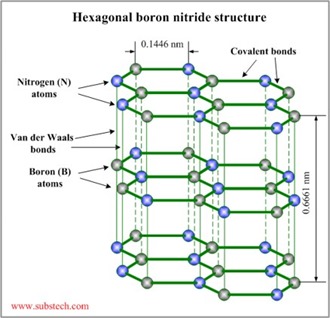

From this SEM image one readily observes a very different particle morphology. This type of morphology is termed “plate-like” since the particles have a very high aspect ration. Aspect ratio is defined as the ratio of the longest dimension divided by the shortest dimension. The SEM image shows a hexagonal BN. The plate-like morphology is a result of the chemical structure of the boron nitride as shown in the following figure:

I like to think about the fillers as marbles (fused silica spheres) or poker chips (hexagonal BN) to get a physical grasp on how the fillers will interact in the thermoset formulation. As we will see in the next series of posts, the rheological properties, coefficient of thermal expansion, thermal conductivity, and electrical conductivity all are significantly impacted by the filler morphology.

Leave a Reply