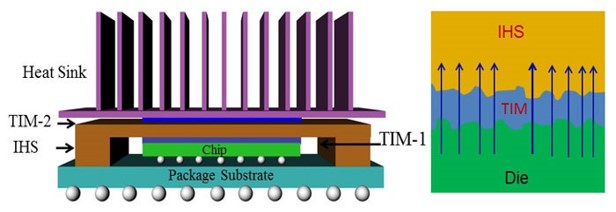

Thermal interface materials (or TIMs) have been used extensively in a variety of electronic packaging to handle heat dissipation from the semiconductor chips as shown in Figure 1.

Figure 1. Schematic of thermal interface materials used in a flip chip package

Figure 1 shows a common configuration for a flip chip package.

Two types of TIMs are used to facilitate heat removal from the chip:

- TIM-1 is placed between the chip (or die) and the integrated heat spreader (IHS)

- TIM-2 is placed between the IHS and the heat sink

The schematic on the right side in Figure 1 depicts the heat flow path. Note that the surfaces of the die and the IHS are typically not smooth and the TIM needs to flow well enabling good contact between the two surfaces in order to get good heat transfer. A subsequent post will discuss interfacial properties in more detail.

In this series of posts, we will focus on the most common type of TIM: polymer-based thermal interface materials. Polymer composite (that is polymer carrier and fillers) account for approximately 87% of the TIM products, with metallic TIMs at 9% and phase change TIMs at 4% (source: BCC Research). Polymers inherently have low thermal conductivity, in the range of 0.2 W/m°K. In order to increase the thermal conductivity, fillers with high thermal conductivity are added to form the polymer composite TIMs.

There are five main types Thermal Interface Materials (TIMs):

- Thermal grease

- Gap filler pads

- Thermal tapes/films

- Phase change materials

- Fully cured dispensed gap fillers

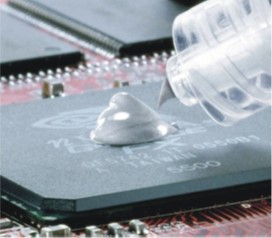

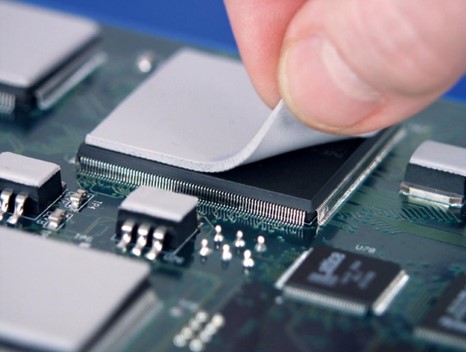

Some examples of thermal interface materials are shown in the following photographs.

Thermal grease and gap filler pads

Films/tapes and phase change materials

Markets

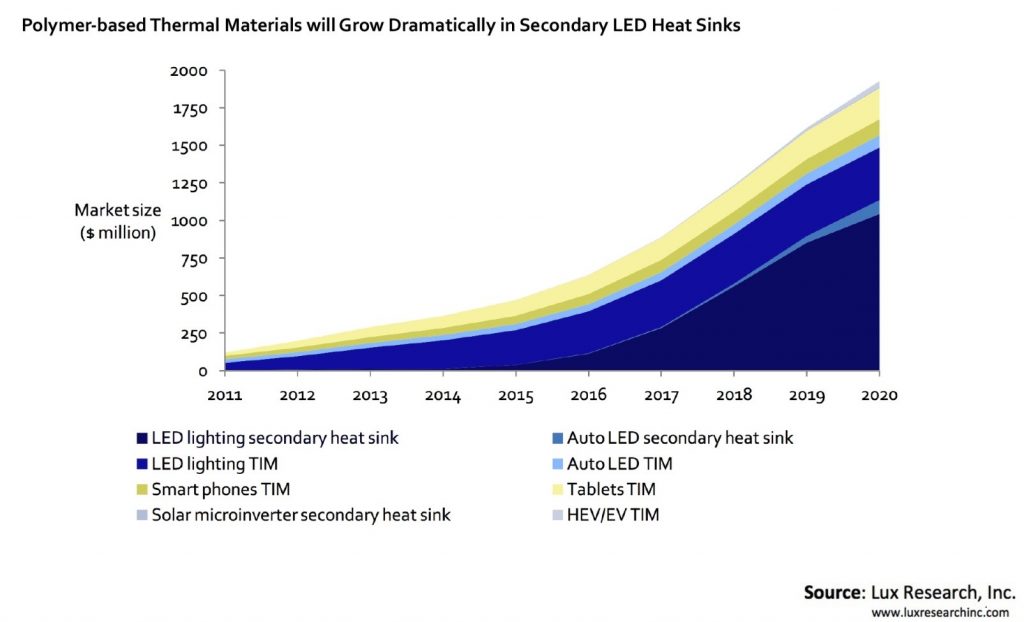

In addition to the mainstream electronic packaging applications for thermal interface materials, there are some emerging new markets. In Figure 2, the market size is plotted as a function of time for polymer-based thermal interface materials. The surprising data in Figure 2 is the rapid growth of TIMs in LED lighting applications.

Figure 2. Thermal interface materials market growth for various segments (source: Lux Research, Inc.)

From Figure 2, the smart phone and tablet thermal interface materials market will triple from about $100 million in 2013 to more than $300 million in 2020. As clearly indicated in Figure 2, LED lighting is emerging as a big driver for thermal interface materials. The Lux Research study did not include the traditional areas for packaging such at the TIM-1 and TIM-2 materials. Thermal management will continue to be important in electronic packaging going forward.

In the last couple posts on Fan-out Wafer Level Packaging, the topic of heterogeneous integration of multiple chips into a single package was presented. At the recent IMAPS meeting in Boston, the Heterogeneous Integration Roadmap (HIR) was presented and subsequently released to the public. In the HIR, the chapter on materials has a section on Difficult Materials Challenges 2019-2029. Click here for a pdf copy. One of the challenges is thermal interface materials with low interfacial thermal resistance and high thermal conductivity with the desired electrical and mechanical properties. The most difficult challenge is for materials with high thermal conductivity and low electrical conductivity (i.e. electrical insulator).

Dear Jeff, is there any material or physical difference between TIM 1 and TIM 2 ?