Guest blog post by Jeremy Pasatta, Advanced Polymer Coatings

Adhesion testing is a critical process in evaluating the performance of coatings, ensuring that they can withstand both environmental and mechanical stress. Poor adhesion can lead to premature coating failure, reducing the lifespan of a product or structure. To prevent such issues, various methods are used to measure adhesion, each tailored to specific applications and conditions. Below, we explore the most widely used adhesion testing methods, their benefits, applicable standards, and the instruments involved.

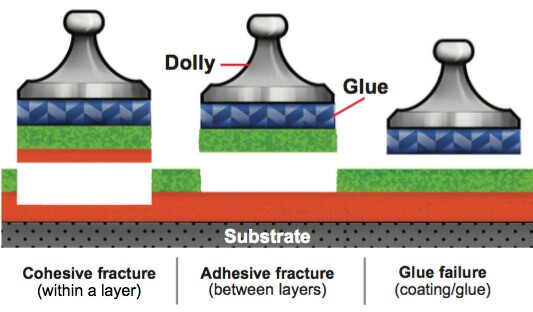

Pull-off adhesion testing is one the most used tests for adhesion of coatings because it is relatively simple and straightforward to perform and provides a quantitative measure of adhesion, as well as being able to distinguish between various adhesive failure modes, such as adhesion to substrate or in multi-layer coatings adhesion failures between layers. This gives the formulator information about the weak areas of adhesion in the coating, which both allows for better formulation and development as well as prediction of failure points in service.

- Standard: ASTM D4541, ISO 4624

- Method: This test measures the tensile force required to detach a coating from its substrate using a hydraulic or pneumatic adhesion tester. A loading fixture, known as a dolly or stud, is glued to the coating, and force is applied perpendicularly until the coating fails.

- Benefits:

- Provides quantitative results in pounds per square inch (psi) or megapascals (MPa).

- Suitable for evaluating thick or multi-layer coatings.

- Instruments: Portable adhesion testers like the Elcometer 506 or PosiTest AT series.

Figure 1 below shows the general types of failure mechanisms that can be observed in a pull-off adhesion test.

Figure 1. Pull of adhesion test [1].

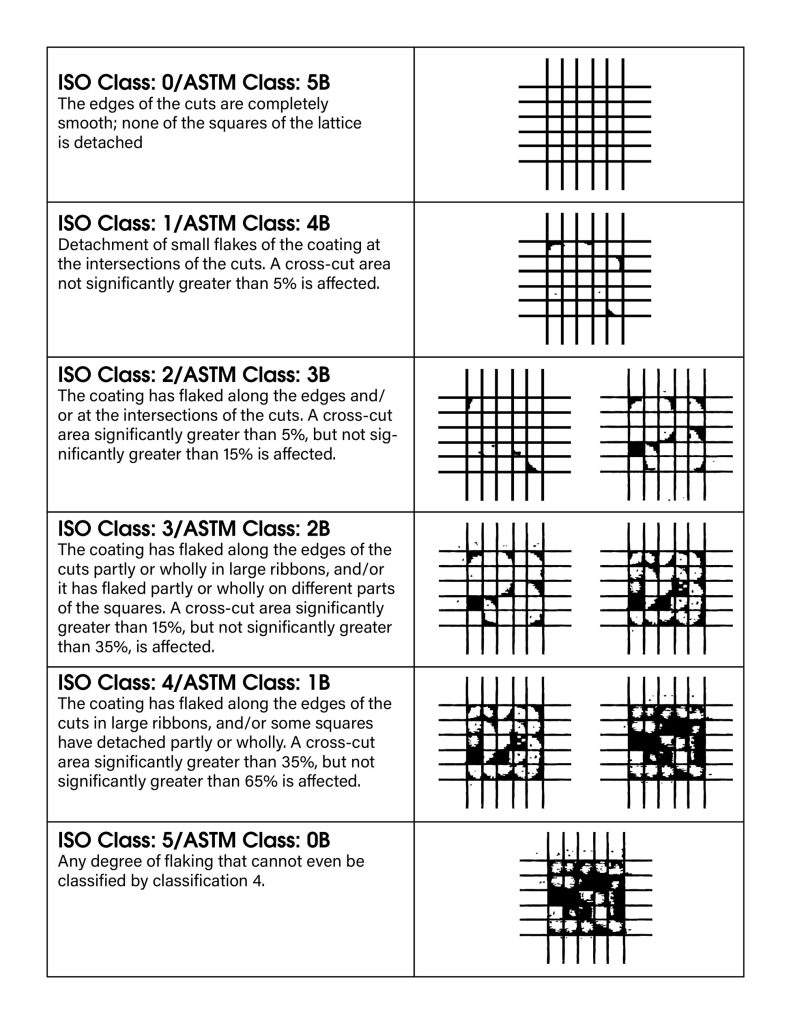

Cross-cut adhesion testing is also a common method of measuring adhesion in coatings, and has gained popularity because of the ease of running the test. This test is often used when a quantitative value is less critical, but rather a comparison between coatings or a qualitative value is sufficient.

- Standard: ASTM D3359, ISO 2409

- Method: A cross-hatch pattern is made on the coating using a specialized cutting tool. Adhesive tape is then applied and pulled off to observe how much of the coating detaches.

- Benefits:

- Quick and inexpensive.

- Ideal for thin coatings on rigid substrates.

- Instruments: Cross-cutting tools with blades of varying tooth spacing, such as those by TQC Sheen or BYK-Gardner.

Figure 2 shows an example of a cross-cut adhesion testing and the ranking of the adhesion.

Figure 2. Cross-cut adhesion standards after tape peel [2].

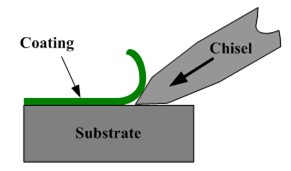

The knife adhesion test is another easy, qualitative method for determining adhesion of coatings. As the name implies, a knife is used to qualitatively determine how difficult it is to remove a coating from the substrate. This method is particularly useful in the field and outside of the lab as a quick check to make sure that a coating was properly applied and cured and shows sufficient adhesion for the application.

- Standard: ASTM D6677

- Method: A utility knife is used to score the coating at a specific angle and pressure, and adhesion is judged visually based on difficulty in removing the coating.

- Benefits:

- Useful for field testing.

- Allows for subjective evaluation of coating toughness.

- Instruments: Utility knives with standard blades.

A general schematic of a knife test is shown in Figure 3.

Figure 3. Knife Adhesion Test Diagram [3].

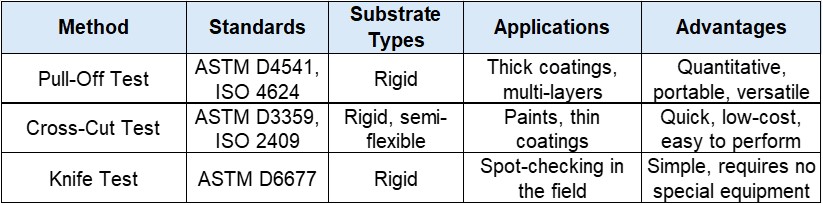

Table 1 below gives a comparison of the three most used methods for evaluating adhesion of coatings.

Table 1. Coating Adhesion Evaluation Comparison.

Below are additional key considerations in evaluating adhesion of coatings:

- Substrate Compatibility: The choice of method depends largely on the substrate’s material properties. For instance, cross-cut adhesion testing allows for a wider variety of substrate flexibility, from rigid to semi-flexible.

- Coating Thickness: Thicker coatings typically require more robust testing like the pull-off method, whereas thin films are well-suited for cross-cut tests.

- Environmental Factors: Testing should account for the coating’s exposure to heat, moisture, or chemicals, as these can affect adhesion

There are several reasons why testing the adhesion of a coating is critical. The first is to maintain quality assurance, and that the coatings meet specified standards for durability and performance. Another reason to measure coating adhesion might be for failure prediction and identifying weak points before exposure to operational stresses. By properly formulating coatings and testing adhesion, costly repairs or recoating due to premature coating failure can be prevented.

Adhesion testing is indispensable for ensuring the long term durability and reliability of coatings. By choosing the appropriate method and adhering to recognized standards, manufacturers and inspectors can confidently evaluate and certify coatings for their intended applications.

References:

Leave a Reply