Guest blog by Dr. Robert Humphreys

If the US Department of Energy, US Department of Agriculture and the biofuels industry have their way, biofuels will dramatically alter American farming. Farmers will produce new crops entirely dedicated to supplying biomass feedstock for biofuels and bio-based chemicals in addition to traditional crops grown for human and livestock consumption. In this post, we will touch on some of the some key aspects of this potential revolution in our nation’s agriculture.

If the US Department of Energy, US Department of Agriculture and the biofuels industry have their way, biofuels will dramatically alter American farming. Farmers will produce new crops entirely dedicated to supplying biomass feedstock for biofuels and bio-based chemicals in addition to traditional crops grown for human and livestock consumption. In this post, we will touch on some of the some key aspects of this potential revolution in our nation’s agriculture.

How much biomass is needed?

The numbers are staggering: a billion tons of dry biomass is a DoE estimate of the amount required to replace 30% of the annual petroleum consumption in the USA. This number is projected for 2030, well beyond the time frame of the Renewable Fuels Standards (RFS2) mandated by the Energy Independence and Security Act of 2007 (EISA) and enforced by the EPA. RFS2 requires 36 billion gallons of renewable fuels to be blended into transportation fuels by 2022, of which 21 billion gallons is mostly from lignocellulosic biomass. Assuming a biomass-to-biofuels conversion of 31.2% by weight, the lignocellulosic biomass mandate of the 2022 RFS will require at least 2.25×108 tons of biomass (Note 1). For comparison, the RFS for 2012 required ethanol production of 13.2 billion gallons. We note that only 12.7 billion gallons actually produced (US ethanol production). Virtually all of this ethanol was produced from cornstarch or sucrose (Note 2). Concern about the impact of biofuel production on food prices has led to an upper limit of 15 billion gallons for ethanol production by fermentation of cornstarch (RFS Overview).

What types of biomass can be used as feedstock for biofuels and bio-based chemicals?

Again, we must refer to RFS2 since biomass that qualifies as renewable must be produced under conditions that result in no “indirect land use changes” and meet criteria for greenhouse gas reduction (see page 6 of RFS Overview for an explanation). Applying these criteria, the following biomass sources qualify as renewable:

- Crop residues (eg. corn stover, wheat straw)

- Residues from forest product production (eg. forest thinnings)

- “Secondary” annual crops, such as winter cover crops

- Food and yard waste, usually a result of municipal waste management

- Perennial grasses

As is typical of complex problems, the devil is in the details. To touch on one example, crop residues are critical to soil quality and erosion control, so massively efficient crop residue collection will be harmful. Consequently, harvesting of crop residues will need to be carefully implemented.

Perennial grasses are “energy crops”, a class of crops that are worth expanding on since they are critical to successful migration from petroleum to renewable fuels.

What “energy crops” crops are we talking about?

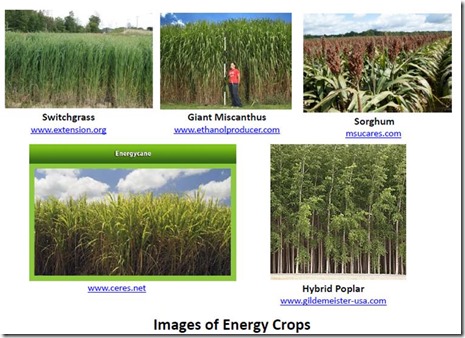

Energy crops are new to US agriculture. Relative to traditional crops, farmers have modest growing experience with most energy crops and no market for them in the absence of a large, viable industry to transform energy crops into biofuels and bio-based chemicals. Different energy crops will be needed to address local variations in soil quality, climate, and water supply. Examples of energy crops that are under development for US agriculture include:

- Switchgrass and other perennial grasses

- Giant miscanthus

- Energy cane, a variety of sugar cane

- Sorghum, usually associated with grain production but also an energy crop candidate because of its productivity.

- Rapidly growing woody crops, including poplar, willow and Loblolly pine.

Many criteria are involved in selection and development of energy crops, such as: is the crop annual or perennial; amount of fertilizer and water required; planting and propagation methods; time to establish a crop; harvesting technology; pests, parasites and diseases; required soil quality; number of annual harvests; yield; potential to be an invasive species; potential to improve the species through breeding and plant engineering; biomass composition, including cellulose and hemicellulose, lignin, and other components such as protein and inorganics; and cost of production. The potential to grow an energy crop on marginal land is important and requirement for minimal fertilizer and water obviously impact production economics.

Summary

This short overview of biomass agriculture gives the reader a taste for the complexity of the renewable energy challenge. However, this is only the beginning; once biomass is harvested, it needs to be transported to a site where it may be dried, transformed into a material that can be conveyed in a processing facility and fed to a reactor, converted to biofuels or bio-based chemicals using technology that is still developmental, isolated and purified, and in the case of biofuels, blended into an acceptable substitute for gasoline or diesel fuel or, in the case of bio-based chemicals, substituted for the equivalent petroleum-based chemical. Creation of a biofuels industry of a scale necessary to supplant a significant fraction of petroleum is an example of trying to manage a complex, adaptive system. Making accurate, 20-30 year predictions about the development of such systems is itself a research problem. To paraphrase Yogi, making predictions is tough, especially about the future…….of biofuels development (see DoE biorefinery projects not ready for prime-time).

In the next post, we will cover the next step in converting second generation biomass feedstock to biofuels and bio-based chemicals, which is logistics.

Notes

1. This value was calculated using a number of simplifying assumptions. The biofuel chosen was isobutanol: density 0.802 kg/l; theoretical, maximum yield of 39% based on biomass sugars (all assumed to be 6-carbon, although hemicellulose is predominantly 5-carbon sugars) and a minimal allocation for fermentation organism metabolic requirements. Biomass composition 80% cellulose/hemicellulose, 20% lignin (discarded). Biomass weight calculated as dry biomass.

2. The maximum theoretical yield of ethanol from starch is 51% by weight. Ethanol is inferior to iso-butanol as a biofuel, see butanol vs ethanol for details.

Thanks for the nice intro/summary to the biofuels challenge, which as you note is very complex. our project, CenUSA Bioenergy is a 5-year, $25 million USDA-NIFA funded project led by Iowa State University. Our goal is the development of a Midwestern sustainable fuels system based on growing perennial grasses on marginal land. You can learn more about our project at http://www.cenusa.iastate.edu.

Oops. Our twitter is @cenusabioenergy