First a few background concepts to get us started. Rheology is the science of deformation and flow of matter under controlled testing conditions. Rheological testing is a powerful way to probe the structure-property-processing relationships in many types of polymers. The viscosity-shear rate profile is important in the processing of thermoplastics (like injection molding and extrusion). For thermosets, rheological measurements provide key insights into the physical changes that occur during the curing process. As discussed in previous posts, during thermoset curing, the gel point (or gelation) defines the process window in that macroscopic flow ceases after the gel point.

First a few background concepts to get us started. Rheology is the science of deformation and flow of matter under controlled testing conditions. Rheological testing is a powerful way to probe the structure-property-processing relationships in many types of polymers. The viscosity-shear rate profile is important in the processing of thermoplastics (like injection molding and extrusion). For thermosets, rheological measurements provide key insights into the physical changes that occur during the curing process. As discussed in previous posts, during thermoset curing, the gel point (or gelation) defines the process window in that macroscopic flow ceases after the gel point.

Due to the long-chain nature of polymers, the deformation history is important. Some key things to consider:

- Everything flows

- The observed properties depend on the time-scale of the deformation, that is polymers can be glassy or liquid-like

- Polymer melts are called memory fluids:

- Properties depend on the deformation history

- Memory fluids exhibit both liquid-like (viscous) and solid-like (elastic)

- Hence the term “viscoeleasticity”

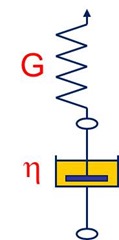

Short deformation times lead to elastic solid behavior. Think of the spring on the left. If you apply a force to the end of the spring, the spring will deform relative to the spring constant (modulus, G). If you release the force, the spring will return to the original starting point (fully elastic). Short deformation times lead to elastics solid behavior.

Short deformation times lead to elastic solid behavior. Think of the spring on the left. If you apply a force to the end of the spring, the spring will deform relative to the spring constant (modulus, G). If you release the force, the spring will return to the original starting point (fully elastic). Short deformation times lead to elastics solid behavior.

On the other hand, if you apply a force to the dashpot (viscous element) that results in deformation at a constat rate for a time which is long compared to the relaxation time, the material will behave in a viscous manner.

Let’s use “Silly Putty” as a good example. If you roll silly putty (which is polydimethyl siloxane) into a round ball and bounce it on the table, the deformation is elastic (i.e. the silly putty ball bounces). An impact is a very short deformation time and leads to elastic behavior.

If you then take the ball of silly putty and pull it slowly the material flows. In this case the time frame of the deformation is long compared to the relaxation time and the material exhibits viscous behavior. Silly putty is a great example of a viscoelastic fluid.

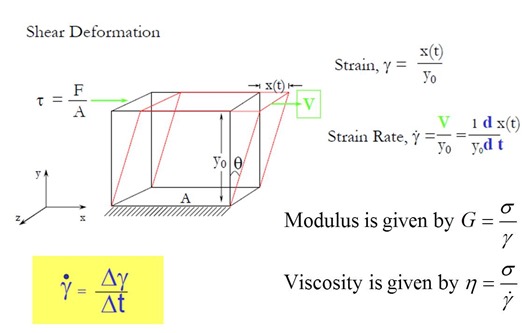

So then, how do you measure the viscoelasticity of polymers (and specifically thermosets)? The answer is a rheometer. A rheometer is an instrument that measures the viscoelasticity of fluids, semi-solids and solids. It also allows the measurement of the viscosity of a wide range of shear rates or shear stresses. Most commercial rheometers measure the viscoelastic properties using a rotational geometry. The most common are parallel plates and cone and plate. In either case, the experiment is the same. Additionally, most commercial rheometers use the simple shear deformation mode:

In simple shear, one surface is stationary and the second surface is deformed with a strain (deformation) or a specified strain rate. The stress is represented by either tau or the stress (s ). As can be seen in the figure above, the modulus is governed by the stress and the deformation (strain) and the viscosity is governed by the stress and the strain rate.

In the next post the various geometries and experimental methods will be presented.

Hi Jeff,

Thanks a lot for all your posts. They are so informative and well done 🙂