Last fall I posted a ten part series on the Rheology of Thermosets (staring August 11, 2014) and covered the basics of rheometry, isothermal and non-isothermal rheology measurements, and finished with a case study on composite lamination. In the next series of posts, I will expand on the composite lamination case study and provide a more in-depth look at how the rheology and chemistry control the flow and consolidation during a composite lamination process. In this series I will introduce another type of rheological test called the squeezing flow test. This has proven to be a very useful and complimentary test to the oscillatory rheometry previously presented. So let’s dive in.

Last fall I posted a ten part series on the Rheology of Thermosets (staring August 11, 2014) and covered the basics of rheometry, isothermal and non-isothermal rheology measurements, and finished with a case study on composite lamination. In the next series of posts, I will expand on the composite lamination case study and provide a more in-depth look at how the rheology and chemistry control the flow and consolidation during a composite lamination process. In this series I will introduce another type of rheological test called the squeezing flow test. This has proven to be a very useful and complimentary test to the oscillatory rheometry previously presented. So let’s dive in.

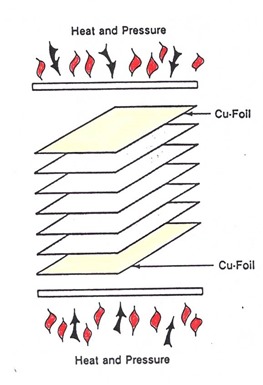

Let’s do a little review before we get started. In the composite lamination process I will be presenting is a squeezing flow geometry. The lamination process involves application of heat and pressure to a stack of B-staged prepregs sandwiched between two sheets of copper foil (if making a “core”) or sheets of prepregs lamaniated between circuitized cores. In most circuit board composite lamination processes, the circuitized cores are manufuctured using copper clad cores and various photolithography processes to impart circuit traces on both sides of the cores. The cores are tested prior to lamination to ensure a high yield after the multilayer stack is laminated and fully cured.

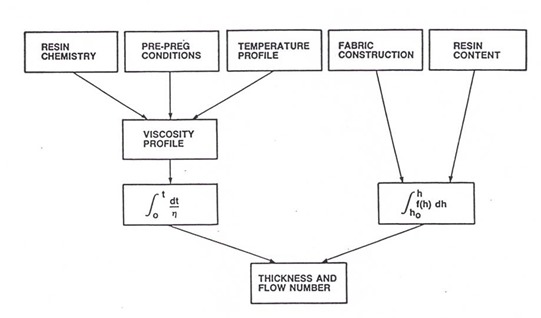

The overall composite lamination process can be represented by the following flow diagram:

There are two components to the lamination process which I call the viscosity integral (left hand side) and the thickness integral (right hand side). I have discussed these in detail in Part 10 (click to view) . Now let’s focus on what is called the flow number and it is the result of the the combination of both the viscosity and thickness components.

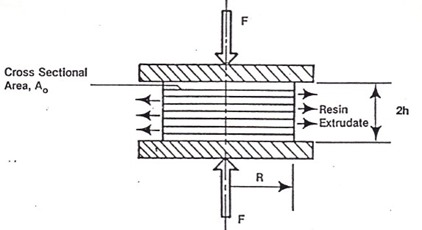

The flow number is obtained using a squeezing flow test. A schematic of the squeezing flow geometry is shown in the following figure:

In the squeezing flow test the number of prepreg plies, heating rate, force (pressure) and cross-sectional area are all defined for the particular test conducted. As one observes, the resin flows radially outward as the B-staged prepreg softens, flows, and then stops at gelation. This test allows the investigation of both the rheology (degree of B-staging and the gel point, i.e. the chemistry) and the prepreg characteristics (resin content and glass cloth thickness)

Two squeezing flow tests will be presented.

- Discrete test based on the initial and final weights of a prescribed sample geometry laminated using a standard heating profile and pressure

- Continuous flow test allowing monitoring of the flow and consolidation process during the lamination process

The objective of the work was to:

- Develop an improved flow test that provides a continuous measurement of resin flow during composite lamination

- Explore the relationship between the viscosity from the flow test and dynamic parallel plate measurements

- Examine instrumented squeezing flow viscometry as a means to characterize resins for composites

This work was done in collaboration with Professor George Martin and his students at Syracuse University. In this series you will see how this fruitful collaboration led to many insights into the composite lamination process.

In the next post we will describe the flow test.

Leave a Reply