Guest Post by Dr. Robert (Bob) Humphreys

Anyone who shops at a supermarket or views commercials for food products or orders food delivery via a phone app should be familiar with the emphasis on fresh produce, healthy and gourmet beverages, preservative- and hormone-free meats, dairy products, and prepared foods, and labels that claim “zero additives”, “no added sugar or high fructose corn syrup”, “all natural ingredients”, and “organic”. Consumer demand for fresh or minimally adulterated food has been rising for several decades and all facets of the food production, sales and distribution system have responded. At the same time, migration of Millennials to central city life and growth in the number of two-working-parent families have led to rapid and continuous innovation in fast food and fully prepared meals that can be purchased from a brick-and-mortar retail facility or rapidly delivered directly to the home, office, place of work, or educational institution.

Fresh, natural, preservative-free, never-been-frozen, minimal processing, organic…..all of these trends present significant challenges to food growers, manufacturers, distributors, retailers, and consumers to ensure that the food is safe for consumption and delivers the nutritional benefits and organoleptic experience that were promised when the food was purchased. Addressing these challenges has led to huge changes in the food supply chain that have affected all stake holders.

Modern Food Packaging: the Yin and Yang

While many of the resulting changes in the food supply chain have remained invisible to the consumer, one change that is very obvious is the rapidly growing reliance on plastic packaging as an essential part of the food supply chain. Plastic packaging in the form of stretch films, tubs, multi-layer films and foil wrappers, sealed pouches, zip-lock bags, bottles, jugs, dispensers, tamper-resistant closures, novel pour spouts, squeezable containers… The list is almost endless and grows constantly. Single serving, easy-open, microwavable, freezable, re-sealable, opaque or high clarity or tinted, attractive graphics that include consumer-relevant information, modified atmosphere, barrier films… Each of these packaging innovations improves or ensures food product quality or safety or convenience or ease of use or adequate shelf life or attractiveness or store shelf impact. The consumer benefits by getting the exact variety of food they want when they want in the quality they desire. This is the yin of plastic packaging.

So, given this rosy picture of improved food products for an increasingly health conscious public, what is the yang? Virtually every trend described above has led to growth in both the volume and complexity of plastic packaging waste. In the United States, disposal of household waste is a local responsibility, usually falling on cash-strapped counties, townships, cities and sometimes states. Environmentally acceptable disposal of plastic packaging waste that has followed population growth and changing consumer lifestyles has placed immense financial pressure on local governments. The low density and exceptional durability of most plastic packaging has complicated collection and disposal. The sheer volume of waste plastic packaging has contributed to full landfills, necessitating investment in incinerators or interstate shipping of the waste with the predictable interstate disputes about accepting someone else’s garbage. Attempts to reduce the disposal problem through plastic recycling have been marginally effective, at best. Such solutions come at a cost, which must be borne by local governments and, ultimately, the taxpayer. For politicians who need to justify rising government budgets and rising taxes for their constituents, plastic packaging waste qualifies as major league yang.

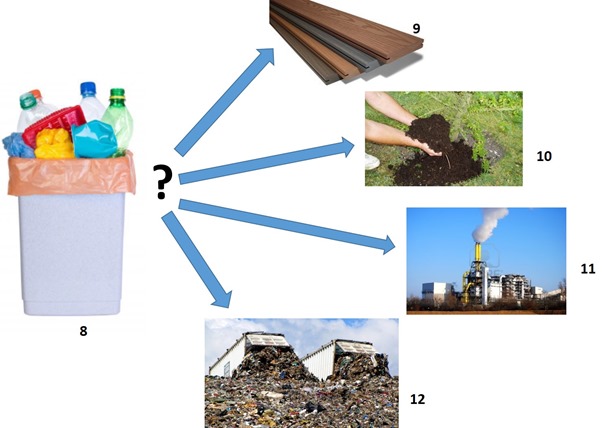

Disposition of Plastic Packaging Waste: What are the Options?

With landfills rapidly falling out of favor, many options for dealing with plastic packaging waste have been proposed or tried. Some examples are recycling, incineration with or without energy capture, composting when the plastic is suitably biodegradable, new technologies that reduce the amount of plastic used in package applications, combining plastics with renewable materials such as paper board to reduce plastic content, and replacing petroleum-derived non-biodegradable plastic with renewable, biodegradable plastics. The simple description of these options masks significant underlying complexity for each. To give one example, while some recycled plastic finds its way into new packaging applications, use of recycled plastic for direct food contact is a major challenge, a consequence of very limited ability to control the quality of recycled plastic. Another example: plastics often include additives, property modifiers, processing aids, fillers, printing inks, labels, and adhesives and in some applications, multiple plastics are laminated together to make a multi-layer film. To add further to the complexity, some plastics with the same name actually come in different types with different properties and ideally, should not be mixed during recycle (e.g. PET, polyethylene). Given the complexity of the food packaging market and the clear and growing preference of consumers for the kind of food products described above, it is likely that the market for plastic packaging will continue to grow in size and complexity and that multiple approaches and significant innovation will be needed to address the growing waste plastic problem.

The Current State of Plastic Food Packaging Waste Disposal and Recycling

It is our experience that much confusion exists about the disposition of plastic packaging waste. For example, what are the rules for plastic recycling, such as who sets the rules, which plastics can be recycled, how often can a plastic be recycled, what applications are suitable for recycled plastic, what problems need to be solved to make recycling a better option for waste plastic…? For biodegradable plastics, what is meant by biodegradability, which plastics are biodegradable and why, under what conditions are these plastics biodegradable, what are the properties of biodegradable plastics, which biodegradable plastics are suitable for food packaging, can biodegradable plastics be composted and what are the requirements, does biodegradability affect packaging performance and economics…? When plastics are incinerated for energy generation, what are the issues and processes required for a clean, efficient incineration?

In the following series of posts, we will attempt to bring some clarity to these and other questions, as well as to provide information on plastics used in food packaging. As always for this blog site, whenever possible, we will provide links to readily available reference material (pdf’s, eBooks, websites) to facilitate further research and identification of additional expertise.

Image Acknowledgements

Images in the figures above are from the following sites:

Packaging 1, Packaging 2, Packaging 3, Packaging 4, Packaging 5, Packaging 6, Packaging 7, Waste packaging 8, Plastic lumber 9, Compost 10, Incinerator 11, Landfill 12

It makes sense that you would want to be careful when it comes to getting rid of waste! Food packaging is one of the most important things in that regard. We consume so much food, so it makes sense that we would want to use packaging that decomposes!