In a previous post, the concept of thixotropy or the shear-rate and time dependency was introduced. Thixotropy develops due to the time required to re-build the particle-particle interactions (i.e. re-form the three dimensional particle network). Unfortunately, for many years, the terms thixotropy and shear thinning were used interchangeably. Recently, a distinction has been made to clarify the terminology:

Thixotropic = shear thinning and time/history dependent

Shear thinning is a very important part of the dispensing performance for a very wide range of highly filled thermoset systems such as thermally and electrically conductive adhesives. In many cases, the viscosity recovery is critical in manufacturing processes where after dispensing, slumping or sagging needs to be avoided. In these cases, the time dependence (i.e. thixotropy) is important in controlling the structure build-up after dispensing in a high volume process.

So when you look at a technical data sheet for a highly filled adhesive you will find a property called the Thixotropic Index (some formulators just call it “thixo” fo short). Let’s discuss what the Thixotropic Index actually measures.

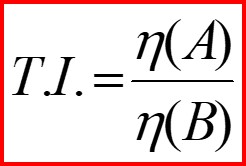

A common quality control test for highly filled thermosets is to measure what is called the Thixotropic Index. A Brookfield viscometer is used to measure the viscosity at two different RPM’s. The Brookfield viscometer is very user-friendly in that the viscometer spindle can be quickly changed to accommodate a wide range of viscosities and the RPM can easily be varied. The Thixotropic Index is given by:

In most cases, the RPM used to measure the viscosity at A is typically a decade lower compared to the RPM used to measure the viscosity at B. For example:

A = 1.5 s-1 or 0.5 rpm

B = 15 s-1 or 5 rpm

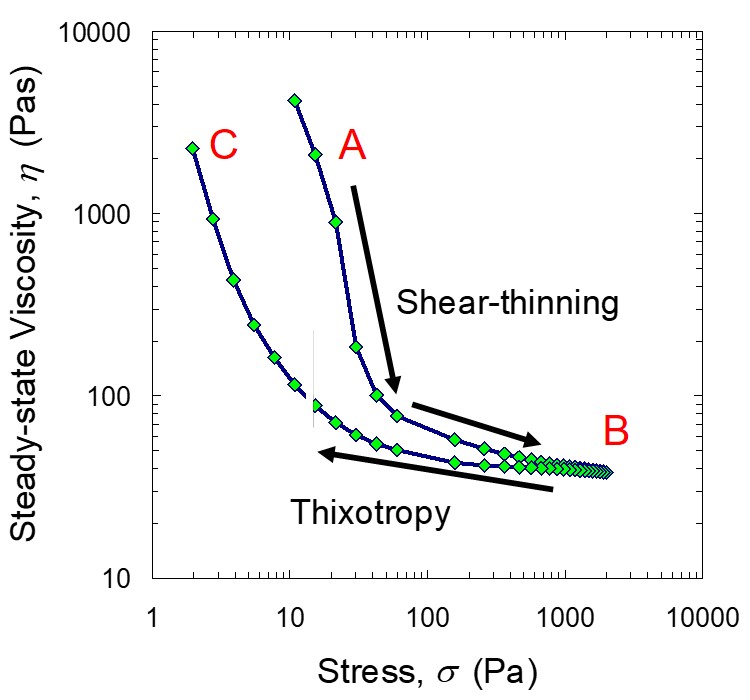

To understand the region where the TI is measured, Figure 1 shows the viscosity as a function of shear rate for a highly filled fused silica/epoxy resin.

Figure 1. Viscosity as a function of shear rate for a fused silica filled epoxy resin.

For this example, the viscosity in the Brookfield at 0.5 RPM corresponds to a shear rate in the rheometer of 1.5 sec-1 and the Brookfield viscosity at 15 RPM corresponds to a shear rate of 15 sec-1 in the rheometer. As we have been discussing, it is important to evaluate the viscosity over a wide range of shear rates for highly filled thermoset systems. It is interesting to note that the TI is measured over a relatively limited shear rate range as shown in Figure 1. The TI is really a measure of the shear thinning index, since the TI relates to how fast the viscosity is changing in the dispensing region. If the viscosity were Newtonian, the TI =1 (that is, no shear thinning). For example, capillary underfills typically have TI’s near 1 since after dispensing the underfill is pulled under the flip chip by capillary force and surface tension. If a capillary underfill had a yield point greater than the capillary force, (i.e. TI >1) the underfill might not flow under the chip. As the material becomes more and more shear thinning, the TI increases. For many commercially available electrical and thermally conductive adhesives, the Thixotropic Index ranges from 3-6. Having a high TI allows the adhesive to not slump or sag after dispensing which is important in a die attach adhesive or a coil bond adhesive used in the actuator arm in a hard disk drive.

Leave a Reply