The rheological properties of polymers used in electronic packaging applications spans a wide range of fluid types and viscosity ranges. In the uncured state, many adhesives, coatings, mold compounds, and underfills have interesting rheological behavior. Many of these types of materials are highly filled to achieve the desired mechanical properties such as low coefficient of thermal expansion, high electrical or thermal conductivity, or tailored modulus. In addition, these materials typically cure to form crosslinked networks with a wide range of physical properties.

The rheological properties of polymers used in electronic packaging applications spans a wide range of fluid types and viscosity ranges. In the uncured state, many adhesives, coatings, mold compounds, and underfills have interesting rheological behavior. Many of these types of materials are highly filled to achieve the desired mechanical properties such as low coefficient of thermal expansion, high electrical or thermal conductivity, or tailored modulus. In addition, these materials typically cure to form crosslinked networks with a wide range of physical properties.

The processing of highly filled formulations can be a challenge. Rheological methods provide a means to characterize the dispensing properties (viscosity, shear thinning, yield points, etc.) as well as probe the viscosity and modulus changes during curing. During curing, the viscosity changes by several orders of magnitude and the material being tested may adhere the parallel plates together (remember we might be characterizing a very good adhesive!), disposable parallel plate geometries are typically used. The parallel plate geometry is better when the temperature is ramped during non-isothermal curing profiles. Additionally, parallel plates can be used for both uncured materials and to measure the viscosity well into the crosslinked region.

There are two types of rotational rheometers typically used to characterize polymers used in electronic applications:

- Controlled stress

- Controlled strain

The viscosity, η, is the ratio of the stress, σ, to the deformation rate (shear-rate, dγ/dt)

To obtain the viscosity, one either measures the stress at a known shear-rate (controlled strain) or measures the shear-rate at a known stress (controlled stress).

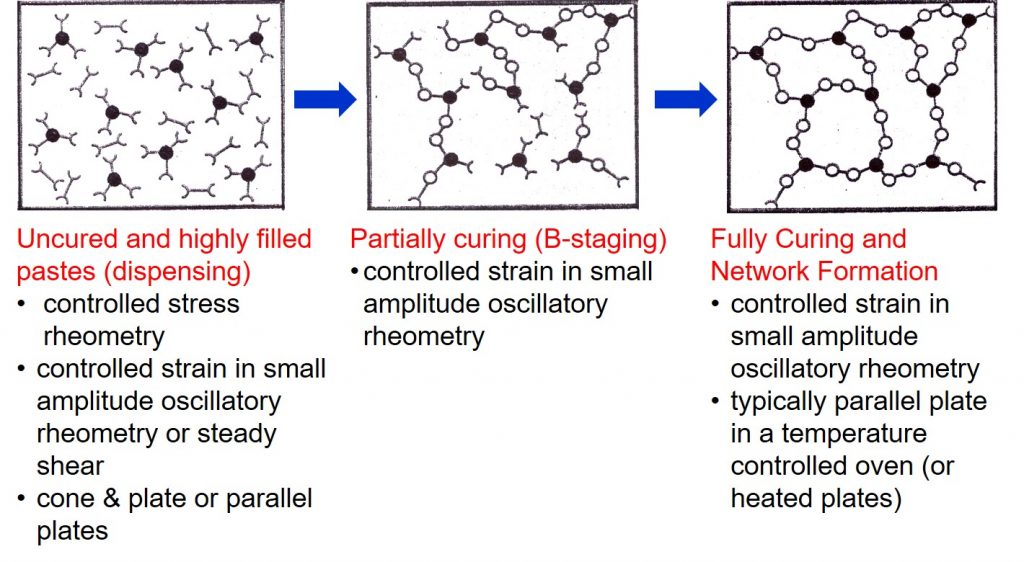

The following figure shows the type of rheological measurement methods used at the various types of processes used in electronic applications.

There are many options to measure the viscoelastic response of uncured and highly filled thermoset formulations. The most common method is to use controlled strain measurements in either oscillatory rheometry or steady shear. In this case, the viscosity is measured as a function of either the shear rate (steady shearing deformation) or the oscillatory frequency. Controlled stress rheometry is a useful method to measure the yield point and shear thinning in highly filled formulations. Controlled stress measurements need to be conducted with care to avoid artifacts. We will discuss controlled stress experiments in detail in subsequent posts.

For high precision steady shear viscosity measurements at isothermal temperatures, the cone and plate geometry is preferred (see below).

The small cone angle (typically less than 3°) results in a uniform shear rate across the cone and plate. Most commercial cone and plates have a truncated cone. The distance between the truncated cone and the plate is 50 µm for cone angles of 1° or 2°. Since expansion of the cone and plate during heating would make maintaining the correct gap difficult, cone and plate measurements are typically done at isothermal conditions.

For non-isothermal curing studies, disposable parallel plates are preferred. Measurement of the viscosity during B-staging or to follow the viscosity build during curing, it is customary to use small amplitude oscillatory rheometry. The strain amplitude is controlled to keep the material under test in the linear viscoelastic region. Subsequent posts will cover in detail the methods used to characterize uncured filled thermosets.

Leave a Reply