In the last post the history of epoxy die attach was discussed. Up until the late 1990’s epoxy was the main thermoset resin used in both conductive and non-conductive die attach. With the drive to get to higher JEDEC moisture sensitivity levels (level 2/260°C and eventually to level 1/260°C) resins with significantly lower moisture absorption were needed. Additionally, epoxies were limited in cure speed and the higher end packages were moving to plastic ball grid array (PBGA) packages. Die attach for PBGA packages were typically non-conductive with a larger die pad requiring closer control of the die attach modulus to manage stress during assembly.

In the last post the history of epoxy die attach was discussed. Up until the late 1990’s epoxy was the main thermoset resin used in both conductive and non-conductive die attach. With the drive to get to higher JEDEC moisture sensitivity levels (level 2/260°C and eventually to level 1/260°C) resins with significantly lower moisture absorption were needed. Additionally, epoxies were limited in cure speed and the higher end packages were moving to plastic ball grid array (PBGA) packages. Die attach for PBGA packages were typically non-conductive with a larger die pad requiring closer control of the die attach modulus to manage stress during assembly.

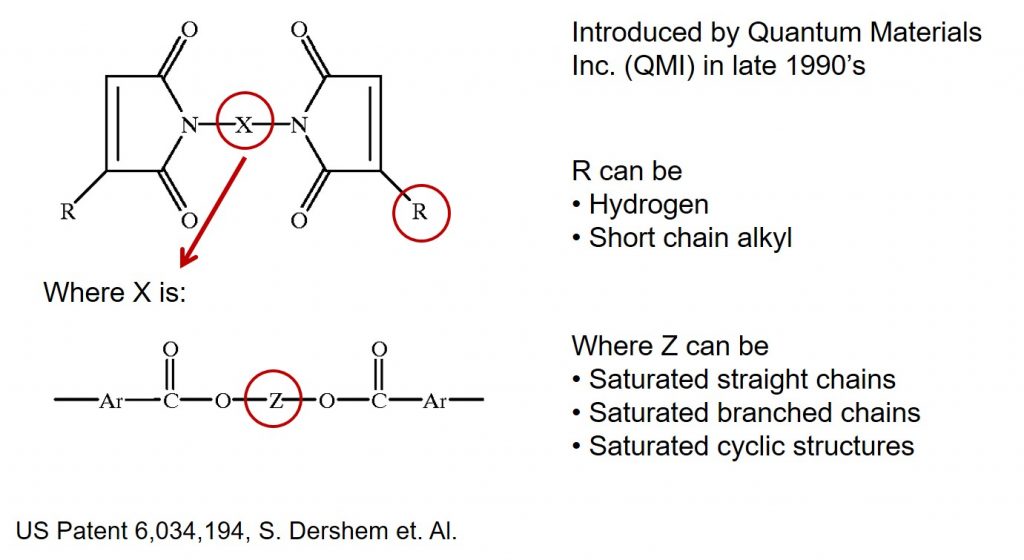

Dr. Steve Dersham at Quantum Materials Inc. (QMI) developed a bismaleimide technology in the late 1990’s (US patent 6,034,194 issued March 7, 2000) that represented a step change in die attach performance. The invention describes a novel solventless adhesive system with suitable viscosity for dispensing and rapid curing. The thermosets are stable to elevated temperatures, are highly flexible and have low moisture absorption. QMI commercialized a series of die attach adhesives in the early 2000’s and gained enough market traction to become an attractive acquisition target. QMI was acquired by Henkel Loctite in the early 2000’s. Under the Loctite QMI brand, multiple adhesives were introduced into the electronics markets.

The bismaleimide chemistry outlined in the Dersham patent is shown in Figure 1.

Figure 1. Bismaleimide structures according to US6,034,194

A wide variety of structures can be produced using this scheme. For adhesive applications, the X segment was typically saturated straight chains. The saturation provided for a hydrophobic resin backbone with good flexibility and low modulus. The synthetic pathway to produce the bismaleimide is shown in Figure 2.

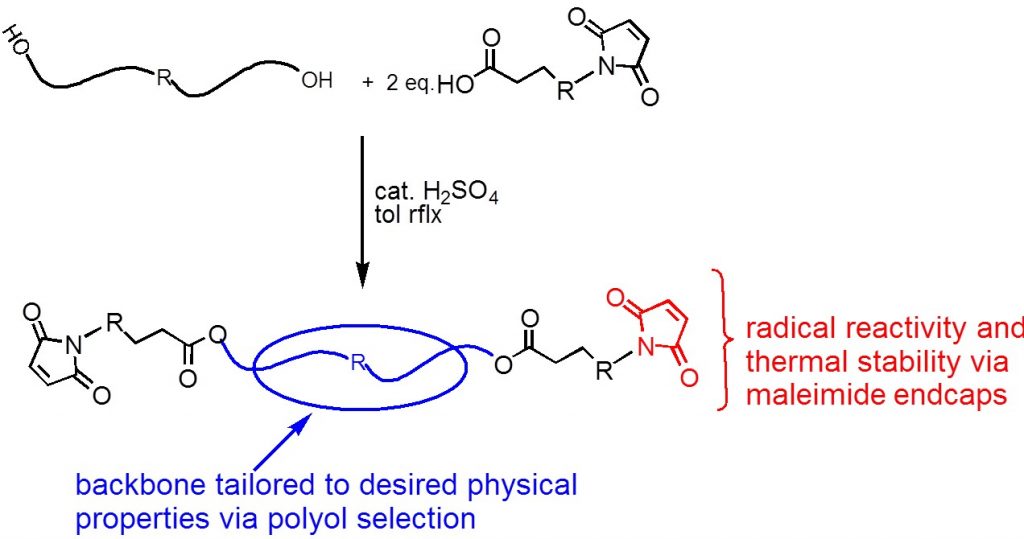

Figure 2. Synthetic pathway for bismaleimide synthesis.

One can envision a “molecular architect” approach to designing new molecules. The structure of the polyol (the X segment in Figure 1) is controlled by the choice of the polyol. The maleimide ends are tailored to provide the desired backbone stiffnes. In the above approach, flexible, low moisture absorption (hydrophobic) adhesives can be developed using appropriate formulation strategies. The maleimide end groups provide a means to get very fast curing through the double bonds using free radical (peroxide) curing agents. Some of the available bismaleimide structures are shown in Figure 3.

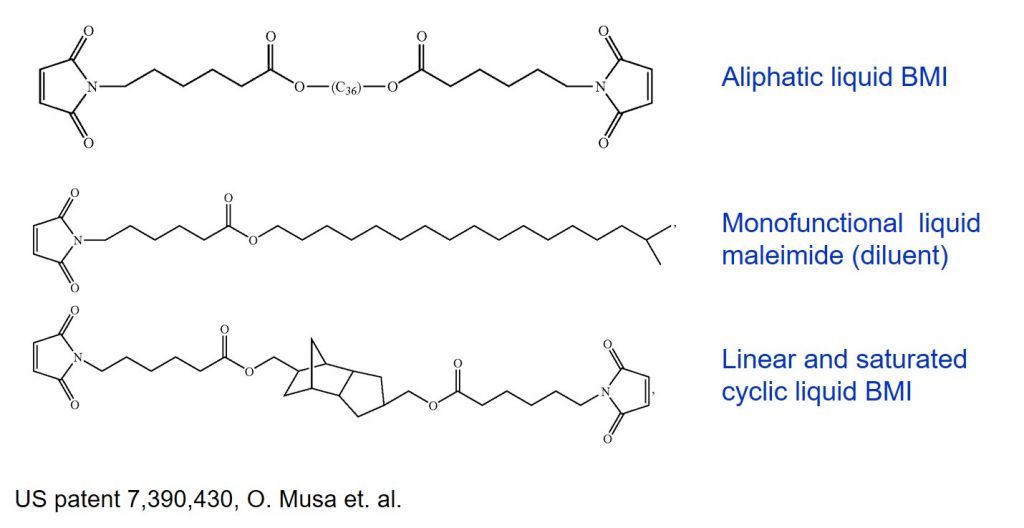

Figure 3. Various types of maleimide monomers for low moisture, flexible adhesives

The top structure is liquid bismaleimide with a long (C36) saturated aliphatic chain between the ester groups. Polymerization proceeds at the imide double bonds at each chain end. The crosslinked network will have high flexibility between the crosslink points and lead to a low modulus, flexible material. The long saturated chain will not absorb water which will help with increasing the reliability level (MSL). The lower image shows an example of a saturated cyclic compound (segment Z in Figure 1) that imparts more stiffness and reduces the molecular weight between crosslink points, thus increasing the modulus and the fully cured glass transition temperature (Tg). By judicious choice of the molecules in the Z segment, the modulus, Tg, flow properties, and moisture absorption can be tailored for the adhesive application.

For example, non-conductive die attach pastes for PBGA are typically needle dispensed onto the array substrate. High filler loading which significantly increases the viscosity, requires the use of a resin with very low viscosity. Reactive diluents are used for two reasons:

- Lower the viscosity to ensure good dispensing in highly filled adhesive formulations

- React into the resin during curing to avoid outgassing and void formation.

If small molecular weight diluents with high vapor pressure are used to lower the viscosity, the diluent molecules may evaporate during the die attach curing process and cause voids. Voids will then lead to reliability issues. With a wide array of potential bismaleimide monomers in the formulation toolbox, multiple die attach formulations were developed by Henkel Loctite under the QMI brand. In the early 2000’s Ablestik also introduced a series of die attach formulations for PBGA, with the most popular being Ablebond 2025D. The Ablebond 2025D Technical Data Sheet describes the chemistry as a proprietary hybrid chemistry. As discussed in the last post, hybrid resins have one reactive group on one end and a different reactive group on the other end. In all cases, the exact molecular structures and formulation ingredients are proprietary.

In the next post we will discuss film die attach used for die stacking applications.

Leave a Reply