The last few posts have been focused on die attach adhesives. For leadframe and PBGA packages, dispensable paste die attach adhesives were used extensively and there are a wide variety of conductive (typically silver filled) and non-conductive (typically silica filled) adhesives on the market today. Over the years, there was a continuous improvement in the performance and processing of die attach adhesives. In the early 2000’s die stacking became important as the applications such as mobile phones required smaller form factor. In order to increase the packaging density, packages needed to have a smaller footprint and analogous to big cities, the “skyscaper” approach (not literally) was used to stack die in the vertical dimension.

The last few posts have been focused on die attach adhesives. For leadframe and PBGA packages, dispensable paste die attach adhesives were used extensively and there are a wide variety of conductive (typically silver filled) and non-conductive (typically silica filled) adhesives on the market today. Over the years, there was a continuous improvement in the performance and processing of die attach adhesives. In the early 2000’s die stacking became important as the applications such as mobile phones required smaller form factor. In order to increase the packaging density, packages needed to have a smaller footprint and analogous to big cities, the “skyscaper” approach (not literally) was used to stack die in the vertical dimension.

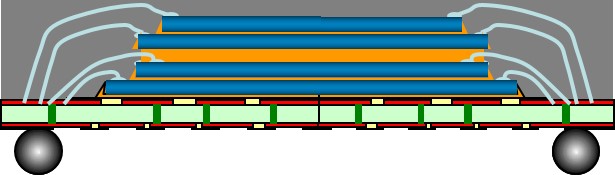

Multiple dies were stacked onto a PBGA substrate as shown in the following figure.

Figure 1. Multiple die stacked on a PBGA substrate

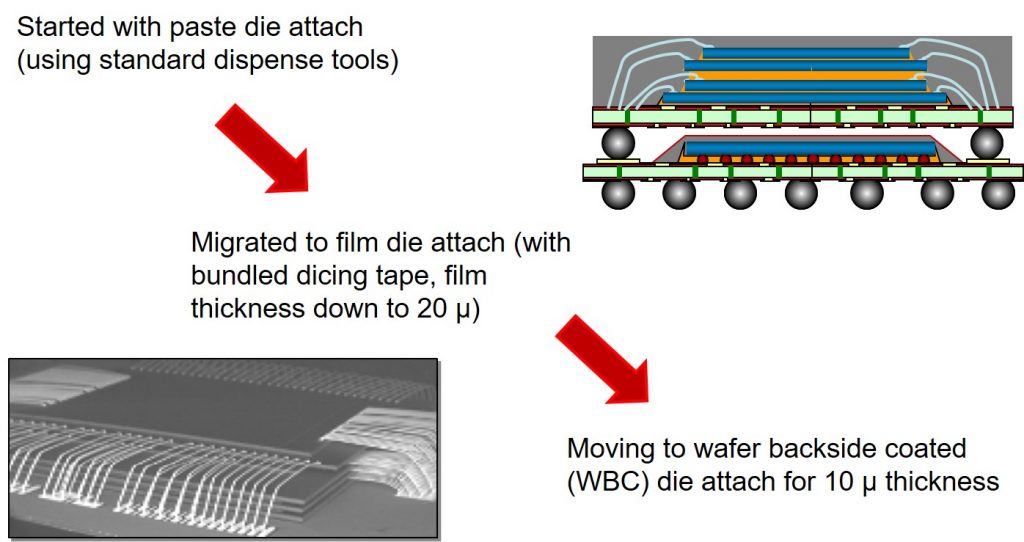

The first approach to die stacking was to modify existing paste die attach (the yellow layers in the image above). This made sense since the OSAT’s (Outsourced Assembly and Test companies that perform semiconductor packaging) had a large installed-base of die attach dispensing machines used in high volume and there were a large number of die attach adhesive suppliers. Some of the early simple multi-stacked dies were successful using paste die attach. In high throughput manufacturing, difficulties were encountered maintaining a precise bondline thickness using standard paste dispensing methods. If the bondline thickness was not uniform, problems would occur during wirebonding. Successive thickness non-uniformity may give rise to “the leaning tower of Pisa” phenomenon where the die stack height variation would cause significant difficulties during wirebonding. The material suppliers responded by developing film die attach materials which would provide much better control of the bondline thickenss. In the image below, the progression of die attach for die stacking is presented.

Adhesives for die stacking require:

- Planarizing the surface of the PBGA substrates

- Precise control of bondline thickness between the stacked dies

- Good wetting and flow during the pick-and-place operation

- Fully cure in the final mold compound cure

There are also multiple geometries for the stacking approach. Pyramid stacking requires each successive die be smaller than the die it is stacked on giving rise to a step where the bond pad is exposed and easily wirebonded. In Figure 1, dies #2 and #4 (counting from the bottom to the top) show the pyramid type stack. The next approach is same-die stacking where the top die is the same size as the bottom die. In Figure 1, dies #2 and #3 are same die stacked. Careful examination of the stacked dies in the above figures shows that for same die stacking the wirebonding process gets more complicated. The bondline spacing has to be large enough to accommodate the wire loop height.

From a polymer perspective, material suppliers responded by developing insulating B-staged thermoset resins that could be coated into very uniform thickness adhesive layers. A wide variety of resins were used from epoxies to polymides. Key performance attributes for film die attach adhesives were:

- Precise control of the adhesive thickness during coating

- Ability to partially cure (B-stage) the film so it could be supplied in roll form

- Compatible with dicing tape since all film die attach adhesives are currently supplied on the dicing tape (dicing die attach film, DDAF)

- Able to soften, flow and achieve good wetting of both die surfaces during pick-and-place

There are currently multiple material suppliers providing various grades of dicing die attach film adhesives. The next few posts will die attach films in more detail.

Leave a Reply