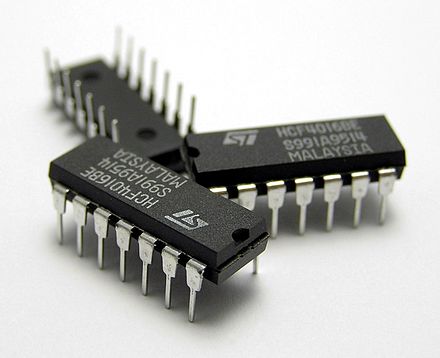

This post will continue our discussion of polymers in electronics by taking a step back and looking at one of the most widely used polymer-based adhesive in electronics: die attach. Nearly all semiconductor chips are bonded to some type of substrate in an electronic package. Note: for those of you who are new to electronics, the term “packaging” refers to the materials used to interconnect the semiconductor chip (or die) to various types of substrates used to electrically connect the chips with various other components. In the picture above (Source: ST Microelectronics), a dual in-line package or DIP is shown. This is a leadframe type of package where the semiconductor chip is attached to a leadframe. In the photo above, two sets of legs (from the leadframe) are visible. The black material that encapsulates the leadframe is epoxy mold compound (EMC). The DIP is known as a pin-in-hole type leadframe package since the leads are typically inserted into plated through holes in a printed circuit board. Notice the shoulders on each pin that allows the smaller lead to be inserted into the plated through hole on the printed circuit board and ensure a uniform stand-off height.

This post will continue our discussion of polymers in electronics by taking a step back and looking at one of the most widely used polymer-based adhesive in electronics: die attach. Nearly all semiconductor chips are bonded to some type of substrate in an electronic package. Note: for those of you who are new to electronics, the term “packaging” refers to the materials used to interconnect the semiconductor chip (or die) to various types of substrates used to electrically connect the chips with various other components. In the picture above (Source: ST Microelectronics), a dual in-line package or DIP is shown. This is a leadframe type of package where the semiconductor chip is attached to a leadframe. In the photo above, two sets of legs (from the leadframe) are visible. The black material that encapsulates the leadframe is epoxy mold compound (EMC). The DIP is known as a pin-in-hole type leadframe package since the leads are typically inserted into plated through holes in a printed circuit board. Notice the shoulders on each pin that allows the smaller lead to be inserted into the plated through hole on the printed circuit board and ensure a uniform stand-off height.

Figure 1. Cross-section of an encapsulated leadframe package

As seen in Figure 1, for a leadframe package, the die attach adhesive is dispensed onto the die pad, the chip is placed, and the die attach adhesive is cured. The next step involve wire-bonding the gold wired from the top of the chip to the leadframe (lead fingers). After wire-bonding, the assembled leadframe is encapsulated with epoxy mold compound.

There are three classifications of die attach adhesives:

- Paste die attach

- Film die attach

- Wafer applied die attach

Paste die attach adhesives are typically supplied in syringes and are pre-mixed and frozen. Pre-mixed means all of the components are mixed during the manufacturing process and then frozen to less than -20°C to essentially quench the reaction. Most of the commercially available die attach formulations are epoxy-based and require an amine or imidazole (amine containing molecule) for curing. At room temperature, the pre-mixed adhesive must have at least a 24 hour work-life as defined by less than 25% increase in viscosity in 24 hours. The pre-mixed adhesives will slowly react at room temperature (since they have very fast cure rates at elevated temperatures) and if the viscosity increases by more than 25% in 24 hours, it is hard to keep the high volume dispensing process in control. An example of a die attach adhesive is shown in Figure 2 (source: Henkel).

Figure 2. Die attach adhesive syringe on needle dispensing equipment

The syringe containing the die attach adhesive is attached to the dispensing equipment and either using pressure (time-pressure dispensing) or auger (screw type) the liquid die attach adhesive flows through a small needle and is dispensed in the required volume onto either the lead frame of the substrate surface (in the photo above, the die attach, QMI 9503) is being dispensed onto the surface of a plastic ball grid array (PBGA) substrate.

Die attach adhesives are typically needle dispensed and must have optimal rheological properties such as shear thinning and tailored yield point. Die attach adhesives are formulated using thermosetting polymers such as epoxies, acrylics, bismaleimides and polyimides. The selection of the base resins is key in defining the fully cured properties. The uncured die attach adhesive contains monomers and oligomers (small starting molecules) to keep the viscosity low. Reactive diluents are used to further lower the viscosity, but are designed to react into the adhesive during curing to prevent void formulation. Additives such as adhesion promoters, conductivity promoters, curing agents and catalysts are added to tailor the curing process and final fully cured properties. Fillers such as silver flake are used for electrically conductive die attach adhesives and silica fillers are used for non-conductive die attach adhesives.

It is helpful to me.

Thanks for sharing.

What is a good die attach material?

Good Workability

• High Throughput(UPH).

• No Tailing No Dripping.

• Low drying during process

• No Resin Bleed

• Low Curing Temp.

• Short Curing Time

• No Void, Good Coverage.

High Performance

• High Adhesion Strength

• Control Bondline Thickness.

• High Electric Conductivity (Electric Conductive demand).

• High Thermal Conductivity

Reliability

• High Temp. High Wet Adhesion Strength.

• Ultra Low moisture uptake.

• Ideal Modulus.

• Low ionic content.

What do you think about this?

Dr. Jeff, may I know if “die attache” means the same as “underfill” ?

Die attach is very different from underfill. Die attach adhesives are used to adhere the IC chip to a substrate. Underfill is flowed under a flip chip mounted IC. See my posts on underfill for a description.