So we’ve talked about technology platforms, open innovation, and how to use a “loose” management approach when conducting applied research and developing technology platforms. The most important aspect of building a robust new product development process is the concept of product architectures.

Product architectures have been used for a while, but don’t really get “a lot of press” in the innovation literature. Product architectures are critical for formulated products such as:

- Adhesives

- Laminates

- Composites

- Coatings

- Electronic materials such as photoresists, underfills, protective coatings, mold compounds, glob tops etc.

Why is this concept so important in formulated products? Since many ingredients typically make up commercial formulated products, it is critical to understand the main effects, interactions, and synergies of the multiple components in a formulation. Additionally, by reducing the formulation complexity, you can reduce manufacturing costs, simplify the supply chain, improve reliability, and develop better products. I challenged one of my teams to develop a new line of adhesives and reduce the formulations complexity at the same time. Typical formulations had anywhere from 16-20 ingredients. The team successfully developed product architectures with 7 components and the products actually performed better. The benefits were:

- Simplified the supply chain by only having to source 7 ingredients

- Reduced manufacturing complexity by only mixing 7 components which saved time and reduced the potential for errors

- Delivered to the market a more robust and more reliable product. Customer complaints on the new product line were reduced by 50%, savings to both the company and improved goodwill with the customer.

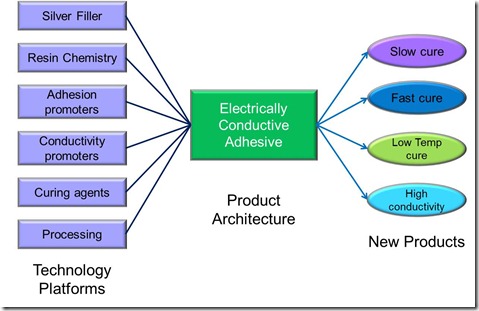

So, what is a product architecture? Think of it as a “blueprint” for a new product. The automobile industry has been using this concept for decades. Think about engines, braking systems, suspensions, frames, etc. The collection of systems that make up the car is a product architecture. OK, buy how does that relate to polymers and formulations? Good question. Let’s take a look at an example of the product architecture for a conductive adhesive:

On the left side are the technology platforms that make up the architecture. Each of the technology platforms provides a key performance characteristic in the formulation. For example, the resin chemistry can be epoxy, or acrylate, or maleimide, or cyanate ester chemistry depending on the type of application. Depending on the substrate to be adhered on there can be a variety of adhesion promoters. The type of curing agent can be selected to control the cure time or temperature. The technology platforms provide ranges for each of the technologies so as you can see on the right, a product architecture can be built to provide various iterations (fast cure, low temp cure, etc.) from the same basic product architecture. The mixing process or order of addition or other key process technology can also be developed as a technology platform and used to build product architectures. The beauty of this approach is that if you build product architectures correctly, it is easy to quickly respond to customer or market demands and make fast product modifications or product line extensions.

In the upcoming posts we will discuss how to integrate technology platforms into product architectures and discuss some critically important design tools that can greatly enhance your ability to quickly build robust product architectures. Yes, I am talking about reducing the total product development cycle time while delivering better, market-focused new products.

Leave a Reply