Organic coatings are used in multiple applications, many we are aware of, such as paints and some most people are unaware of such as in aluminum interior can coatings. For the sake of clarity, all the coatings discussed in this series will be organic-based and may be referred to simply as “coatings.” Coatings are generally grouped into four main categories [1].

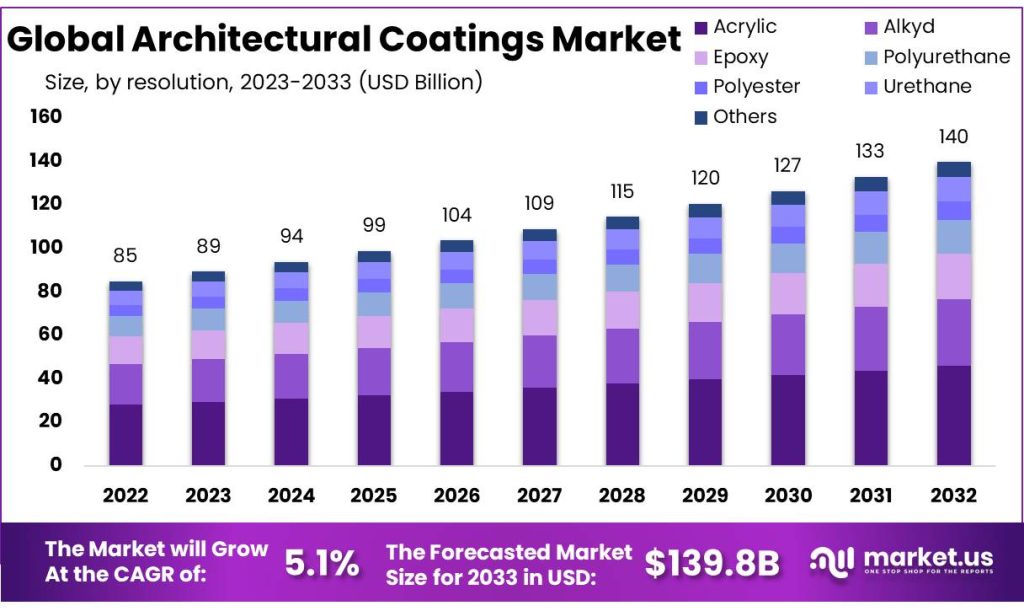

The first is architectural coatings that include paints and varnishes (transparent coatings) that are used to decorate and protect buildings and homes on the inside and outside. This classification also includes paints and varnishes used in the home for furniture and cabinets. The global architectural coatings market is forecasted to be approximately $140B by 2033 with a compound annual growth rate (CAGR) or 5.1% from 2022 to 2032.

Figure 1. Global architectural coatings Market [2].

As seen in Figure 1, acrylic coatings comprise over 33% of the applications followed by alkyd and epoxy resins [2]. Other base resins specified in this category are polyurethane and polyesters.

The second major coating classification is product coatings sometimes referred to as industrial coatings. These are the coatings that are applied in a manufacturing plant and sometimes called OEM (original equipment manufacturer) coatings. These types of coatings are used in industrial applications such as automotive paints, appliances, aircraft, furniture, aluminum can coatings, and electrical applications such as protective coatings for electronic components.

The third category is special purpose coatings which include industrial coatings applied outside the factory and include marine coatings, automotive after-market coatings, maintenance paints for steel bridges, interior and exterior coatings for storage tanks, striping on highways and parking lots, among many others.

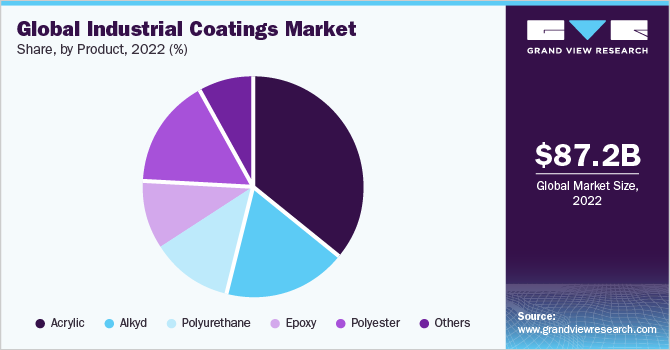

Market research data typically combines the second and third categories into one classification of industrial coatings. The global industrial coatings market was $87.2 billion in 2022 and $89.7 billion in 2023. The industrial coatings market is expected to grow at a CAGR of 2.1% from 2023 to 2030 to a market size of $106.6 billion [3]. The most common resins used in industrial coating applications are acrylic, alkyd, polyurethane, and epoxy.

Figure 2. Global Industrial Coatings Market in 2022 [3]

The acrylic product segment was the largest share in 2022 with approximately 36% of the overall revenue [3]. Acrylics are widely used in the industrial coatings segment due to having good corrosion resistance, good adhesion, barrier properties and fast-drying capabilities. Alkyd industrial coatings are used in an industrial environment for metal coatings. Alkyd coatings have good gloss & color retention and corrosion resistance. Epoxy coatings are widely used in many industrial coating applications. Epoxy coatings have good abrasion resistance, fire resistance, vapor permeability, UV light resistance, high weathering resistance, and gloss retention [3].

The last category is miscellaneous paint and coating products, which includes thinners, paint removers, pigments dispersions, and others.

To meet the market demands and coating properties described above, coating formulators have an extensive “formulation toolbox.” Polymer-based coatings are typically a complex mixture of many ingredients. There are four major components in a coating formulation:

- Binder or resin (usually a thermoset resin system)

- Volatile components (solvent or aqueous)

- Additives

- Pigments and fillers

Resins used in coatings are covered extensively in references 1, 4-5. The next posts in this series will focus on additives, specifically anti-foam agents (control of surface finish), wetting agents, adhesion promoters, fillers, reactive diluents, and the drive towards low volatile organic content (VOC) coatings.

References

- Wicks, Zeno Jr., Jones, Frank, Pappas, Peter, and Wicks, Douglas, (2007) Organic Coatings, Science and Technology, Third Edition, John Wiley and Sons, Hoboken, NJ, ISBN 978-0-471-69806-7

- https://market.us/report/architectural-coating-market/

- https://www.grandviewresearch.com/industry-analysis/industrial-coatings-market

- Ratna, D. (2022) Recent Advances and Application of Thermoset Resins, Second Edition, Elsevier, Amsterdam, Netherlands, ISBN 978-0-471-69806-7

- Dodiuk, H editor, (2022) Handbook of Thermoset Plastics, Fourth Edition, Oxford, United Kingdom, ISBN 978-0-12-821632-3

Leave a Reply