Guest blog post by Jeremy Pasatta, Advanced Polymer Coatings

High performance thermoset coatings are used in a variety of applications, from marine to protective and industrial applications. One of the key components for success of these coatings is adhesion to a variety of substrates, which is facilitated using adhesion promoters. These specialized chemicals play a pivotal role in enhancing the bond between the coating and the substrate, thus significantly influencing the overall quality and longevity of the finished product.

Adhesion promoters are substances added to coatings to improve their adhesion to substrates and are selected based on both the type of thermoset used in the coating and the type of substrate. In the context of thermoset coatings, these promoters are essential because thermoset resins, such as epoxy, polyester, and polyurethane, undergo a curing process that can sometimes lead to poor adhesion to various surfaces. Adhesion promoters address this challenge by chemically interacting with both the substrate and the resin to form a strong bond at the interface of the coating and substrate.

Adhesion promoters can be broadly categorized based on their chemical nature and the mechanism by which they enhance adhesion. Here’s a detailed look at the primary types:

Silane-Based Promoters

- Chemistry: Silanes contain reactive groups that can bond with both inorganic surfaces (like glass or metal) and organic resins. Typically, a silane molecule has an organofunctional group, such as amino, epoxy, or methacrylate, attached to a silicon atom that forms covalent bonds with the substrate and resin.

- Mechanism: Silanes undergo hydrolysis to form silanol groups, which then condense with each other or react with surface hydroxyl groups. This process creates a robust siloxane network that enhances adhesion.

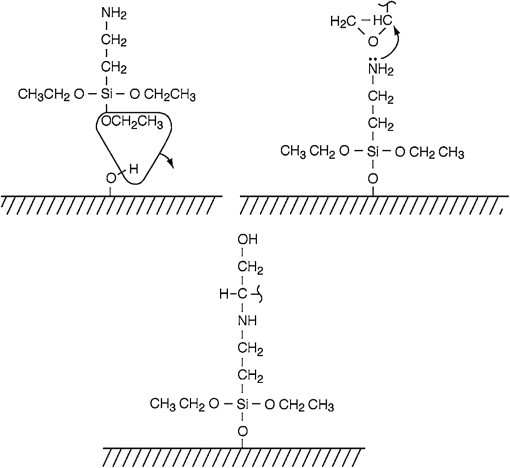

The general structure of an amine functional silane adhesion promoter and its mechanism in an epoxy based coating is shown in Figure 1.

Figure 1. Amine functional silane adhesion promoter mechanism in an epoxy coating [1].

Titanate-Based Promoters

- Chemistry: Titanates are organotitanium compounds that contain titanium atoms bonded to organic groups. These promoters are particularly effective with metal substrates and ceramics.

- Mechanism: Titanates form complex chemical bonds with metal oxides or hydroxyl groups on the substrate surface. This interaction improves the wetting and bonding of the resin to the substrate.

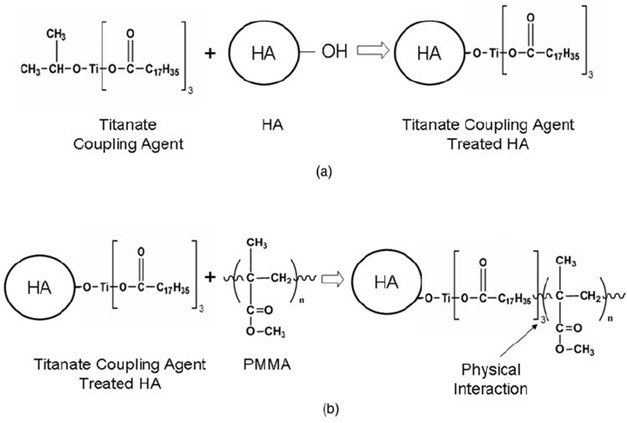

A possible mechanism for a titanate adhesion promoter in a PMMA matrix with a substrate containing hydroxyl groups is given in Figure 2.

Figure 2. Mechanism of a titanate adhesion promoter with a hydroxyl functionalized substrate and PMMA matrix

Zirconate-Based Promoters

- Chemistry: Like titanates, zirconates are organozirconium compounds. They are used to enhance adhesion to glass, ceramics, and metals.

- Mechanism: Zirconates interact with metal oxides and hydroxyl groups through a similar mechanism to titanates, providing improved adhesion and resistance to environmental factors.

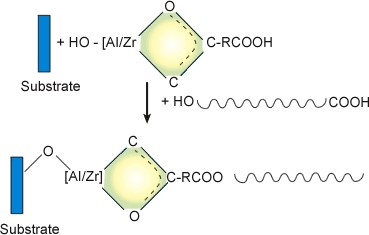

The mechanism of adhesion promotion for a zircoaluminate adhesion promoter in a alkyd or polyester based coating is shown in Figure 3.

Figure 3. Mechanism for a zircoaluminate adhesion promoter

Polymeric Promoters

- Chemistry: These include various polymeric compounds that contain functional groups capable of reacting with both the resin and the substrate. One example of a polymeric adhesion promoter is a maleated polymer, where the maleic anhydride functional groups are capable of reacting with the substrate, and the polymeric portion of the adhesion promoter has an affinity for the thermoset resin. Polymeric adhesion promoters can also be non-functional, such as block copolymers, where one block has an affinity for the substrate and the other block has an affinity for the resin, creating a physical rather than a chemical adhesion between the substrate and the coating.

- Mechanism: Polymeric promoters improve adhesion by creating a chemical bridge between the substrate and the coating, leading to enhanced mechanical interlocking and surface energy modification.

The primary function of adhesion promoters is to modify the interface between the substrate and the coating. This involves several key mechanisms:

Surface Activation: Adhesion promoters activate the substrate surface, making it more reactive and increasing the chemical compatibility with the coating. This is particularly important for non-metallic substrates such as plastics.

Formation of Intermediate Layers: By creating a molecular intermediate layer, adhesion promoters facilitate better bonding between the coating and substrate. This layer often consists of silane, titanate, or zirconate groups that chemically interact with both surfaces.

Enhanced Wetting: Adhesion promoters improve the wetting properties of the coating, allowing it to spread more uniformly over the substrate. This results in a more even application and a stronger bond.

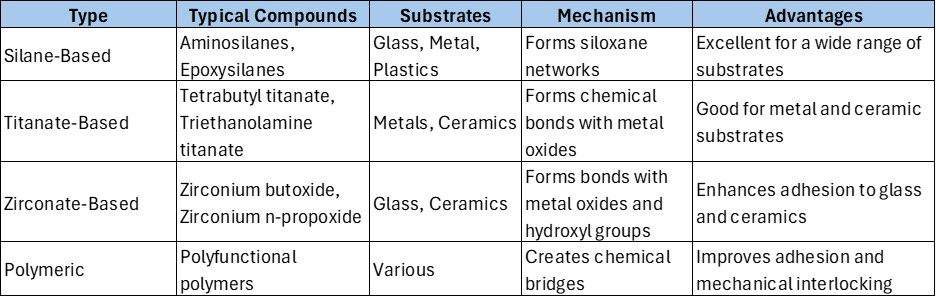

Table 1. Comparison of Adhesion Promoter Types

Adhesion promoters are indispensable in the formulation of high-performance thermoset coatings. By selecting the appropriate type of adhesion promoter based on the substrate and the coating system, manufacturers can significantly enhance the adhesion properties, leading to improved durability and functionality of the coatings. Whether it’s silane, titanate, zirconate, or polymeric promoters, each type offers unique advantages tailored to specific applications and substrates. Understanding their chemistry and mechanisms can lead to better formulation practices and ultimately more reliable and long-lasting coatings.

References.

- Adhesion Promoters, Peter G. Pape, in Applied Plastics Engineering Handbook, 2011

- October 2011, Journal of Composite Materials 45(22):2335-2345

- https://www.manchem.com/mechanism/

Leave a Reply