Guest Post by Dr. Lawrence Judovits, Arkema, and Dr. R. Bruce Prime

In the previous posts in this series we have described the principles of modulated temperature DSC and its application to the cure of thermosets. In this post we describe the characterization of a common two-part epoxy, Devcon® 5 Minute Epoxy, that is readily available at hardware stores and home improvement centers, . The following characteristics are listed on the packaging for room-temperature cure.

Handling time: 5 minutes

Set time: 8-10 minutes

Cure time: 1 hour

The only additional information given is “if temperature is below 40 °F (5 °C) the hardening time is considerably longer”. For comparison the packaging for Gorilla® 5 Minute Epoxy lists a Set time of 5 minutes, a Handling time of 30 minutes and a Cure time (load bearing) of 24 hours. Loctite® 5 Minute Epoxy lists an Open time of 5 minutes, a Handling time where objects can be moved of 20 minutes, a Time to achieve usable strength of 30 minutes and a Sanding/machining time of 24 hours. And J-B Weld® 5 Minute Epoxy lists a Set Time of 5 minutes, a Cure time of 1 hour and a Full cure time of overnight. It’s hard to know what to expect when, so let’s see what we can learn from MTDSC.

Devcon® 5 Minute Epoxy is a clear general purpose adhesive sold in a packet as a two component cartridge syringe system. Because of the amount of sample needed for the large number of runs performed, three packets were purchased. To distinguish packet-to-packet variability we designate samples from the first packet purchased as Sample A, those from the second packet as Sample B and those from the third packet as Sample C. Before each use, both cartridge sides were first burped by squeezing out some material until both sides were devoid of air bubbles. Both liquids were then simultaneously introduced into an aluminum dish in approximately equal amounts and vigorously mixed. After mixing a small amount, less than 15 mg was inserted into a DSC pan bottom and a lid placed on top in contact with the glue. The pan bottom and lid were pre-weighed and the sample mass determined after curing. Elapsed time between the start of mixing and the start of the DSC measurements was 1½ to 2½ minutes.

MTDSC measurements were performed in a TA Instruments Q2000 by first quenching to -50 °C, or lower, and then using a ramp rate of 2 °C/min with an amplitude of ±0.212 °C with a period of 40 seconds.

Because this system is so fast to react we decided to perform first and second heat measurements to track the cure at various times from right after mixing to 24 hours at 25 °C.

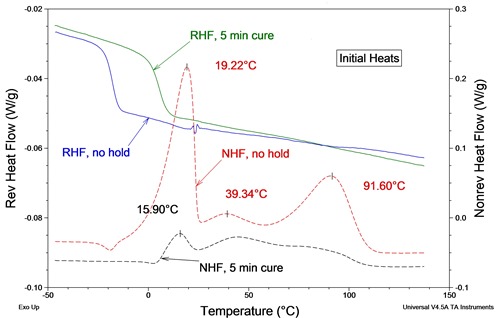

We started with a survey run immediately after mixing the components from the first packet (Sample A, ‘no hold’ in figure below). The sample was quench cooled to -50 °C before heating to 140 °C. We first see a step change in the RHF indicating a Tg at -18 °C. Following that are three exotherms illustrating the complexity of the cure process. The first and largest exotherm (Rxn 1) has a maximum at 19 °C (66 °F), the second and smallest (Rxn 2) at 39 °C and the third (Rxn 3) at 92 °C. The onset for Rxn 1 well below 0 °C and reaching a maximum rate at 66 °F highlights the room temperature reactivity of this system. On the second heat (not shown) a single Tg was observed at ~24 °C. We speculate that the curing system is a mixture of curing agents with differing reactivities, perhaps three different amines, plus catalyst to accelerate the reaction.

Sample A epoxy after five minutes at 25 °C is overlayed with the survey run in the figure below. The Tg has moved up to 5 °C and the Rxn 1 exotherm is much smaller. Note the significant reduction in the high temperature Rxn 3 exotherm. Also note that the peak temperature for Rxn 2 increases while that for Rxn 3 decreases, resulting in the two reactions becoming less well resolved.

Devcon® Sample A, immediately after mixing and after a five minute cure at 25 ˚C. The MTDSC parameters were a 2 °C/min heating rate with an amplitude of ± 0.212 ºC and a period of 40s.

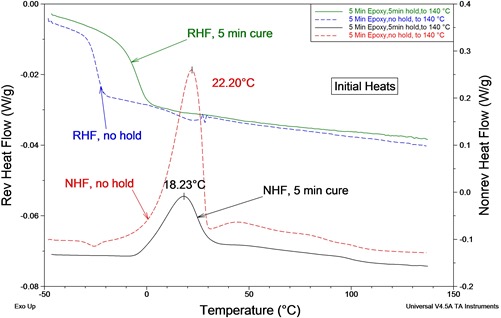

Devcon® Sample C, immediately after mixing and after a five minute cure at 25 ˚C. The MTDSC parameters were a 2 °C/min heating rate with an amplitude of ± 0.212 ºC and a period of 40s.

A similar overlay is shown for Sample C from the third packet purchased in the figure above, illustrating that while overall behavior is similar there are distinct packet-to-packet variations. Especially note the higher peak exotherm temperature for Rxn 1, sugesting a slightly less reactive system, and the reduced contribution of Rxn 3. Results for Sample B from the second packet will be shown in our next post.

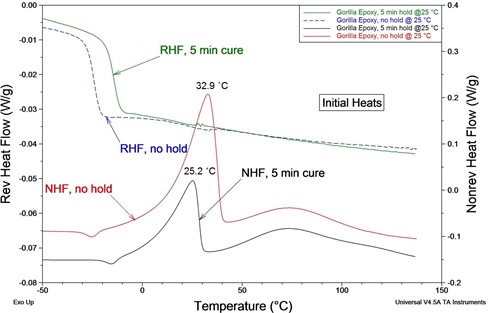

For comparison we show an overlay for Gorilla® 5 minute epoxy below, illustrating significant differences with Devcon® 5 minute epoxy. Gorilla® has only two exotherms compared with Devcon’s® three, suggesting simpler chemisty. And Gorilla’s® low temperature exotherm peak is 10-13 °C higher than Devcon’s® (Rxn 1) suggesting that it will be slower to react, which is supported by the smaller increase in Tg from immediately after mixing to 5 minutes at 25 °C. Also note that this exotherm is skewed to the low temperature side while that for Devcon® is symmetrical.

Gorilla® 5 minute epoxy, immediately after mixing and after a five minute cure at 25 ˚C. The MTDSC parameters were a 2 °C/min heating rate with an amplitude of ± 0.212 ºC and a period of 40s.

In our next post we describe the cure of 5 minute epoxy on two levels, Tg – time data at 25 ˚C and observations of changes in physical state during cure.

Devcon® is a registered trademark of Chemical Development Corporation; Gorilla® is a registered trademark of Lutz File & Tool Co.; Loctite® is a registered trademark of Henkel Corporation; and J-B Weld® is a registered trademark of J-B Weld Company, LLC.

Hey,

Very interesting article!

We deal with epoxy on a daily basis and the “curing” and timing is the part that makes all the difference.

This has been really informative.

Thanks