This is the final post in the 8 part series and here we will explore how to rapidly exploit all of the hard, but focused work you have done to build a robust product architecture. Using the electrically conductive adhesive example, let’s say your first product was a fast cure, but required a high cure temperature. Your first customers like the faster curing times which saves them money due to increased throughput, but they want to get additional energy savings using a lower cure temperature. And as long as you are making a modification, the market needs a higher electrical conductivity as well.

In the “old days” a typical formulator would search existing products for something close to the customers CTQ’s and then start tweaking the formulation by adding ingredients to lower the cure temperature and increase the electrical conductivity. This was the trial and error method, since most of the time there was little understanding of how the original formulation actually worked.

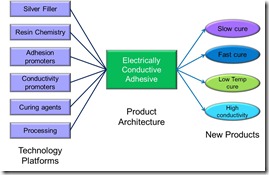

Since we have been using a product architecture approach, it is likely that during the architecture development, an understanding of the key factors governing cure speed and electrical conductivity were developed. Remember we called these technology platforms such as the curing agents and conductivity promoters, such as the components on the left side in the figure above. The beauty of product architectures is that the main components of the formulation are already in place, so the formulation scientist does not have to start from scratch. Being able to modify an existing product architecture has the following advantages:

- Shortens development time for product modifications

- Enables rapid product line extensions if required

- Uses existing manufacturing processes

- Leverages a known, robust product architecture (product architectures are extensively tested during the initial development to ensure consistent performance at the customer)

We have spent the last 8 posts talking in detail about how to use a systematic process to enable formulation science. For many, this may seem like a cumbersome and slower way to develop products. It takes a major thinking shift in the beginning, but once you get your technology delivery process in place it actually takes less time to commercial revenues. I have seen all too many times in the past where the formulators did a rush job to get a formulation out to the customer only to find major problems during qualification. The customer has to wait while re-formulation occurs, then re-testing. The many iterative loops take a lot of time and burn valuable goodwill with your customers. If you have spend the right time upfront learning about your customers needs, then you will be ahead of them. Wayne Gretzky once said “I skate to where the puck is going to be, not where it has been.” If you drive your technology delivery system to produce products where the customers are going to be, then you will enjoy much commercial success.

Leave a Reply