The fourth key to innovation success is to utilize Open Innovation as a regular part of the development process. Companies must realize that they cannot rely completely on internal R&D for all of their development work. Effective use of outside resources, i.e. open innovation is a great way to accelerate your research and product development efforts. So what is open innovation and why is it so important?

Open Innovation is a term promoted by Henry Chesbrough, a professor and executive director at the Center for Open Innovation at UC Berkeley, in his book Open Innovation: the new imperative for creating and profiting from technology1. The main concept of open innovation is expanding the boundaries of your company and looking outside for some of your technical solutions. Open innovation is not new, but has become a necessity with the acceleration of new product development and the increasing breadth of technology required for truly innovative products.

Let me give you some examples in the area of polymers to demonstrate how open innovation can be a huge advantage to your organization. Back in the mid 1980’s when I was at IBM, my research was on the next generation of thermosetting polymers for complex multilayer circuit boards. I used an open innovation approach to help me tackle two critical issues. The first was how to control the crosslinking kinetics during curing of the next generation epoxy resins. IBM had a program called Sponsored University Research (SUR). I had a multiyear contract with Syracuse University to study an important class of new crosslinking agents. We gained a fundamental understanding of the chemistry and chemorheology so that when the time came to do the product development work, we had the solution ready. Remember in a previous post we talked about developing platforms, we this was also a good example of developing enabling technology for our next generation resin platform. Another example was to develop a detailed understanding of the fundamental issues leading to warpage, a key performance requirement for semiconductor packaging substrates. In this case we partnered with Northwestern University to develop experimental methods to measure warpage (shadow moiré) along with predictive models to reduce warpage. We didn’t have these specific skills inside IBM at the time, so we went outside. We used open innovation. In both cases we leveraged outside sources of technology to solve key internal challenges.

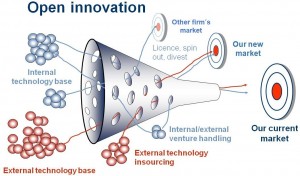

Let’s look at the figure taken from the work of Henry Chesbrough2.

The figure depicts the many ways technology can either go into your development pipeline or how you can spin-out technology that is not core to your business. Most companies have an internal technology base where they have several solid core competencies. Leveraging your internal technology capability constitutes a major portion of your development portfolio. Other avenues to acquire technology would be joint development partnerships, licensing agreements (both licensing external technology for your products as well as licensing out non-strategic technology). Another area is to acquire a new technology, bring it in-house and develop products to enter a new market, thereby expanding your revenue base. The key aspect of the figure is that the boundary of the corporation (the cone leading to the product development pipeline) is porous and allows technology to come in and out.

Another good polymer example was a development project for a new electrically conductive adhesive. The filler was a key component of the formulation and we had very close partnerships with our filler suppliers. The R&D teams in both companies worked together to develop technologies to get to very high electrical conductivities. In this case, the use of specific chemicals were required to prepare the filler surfaces so that during the adhesive curing effective particle-particle packing was achieved leading to high electrical conductivity. We went outside our R&D group and partnered to get the right technology for the specific application.

An example of leveraging technology that you have already developed is to actively pursue licensing agreements. IBM has a very active licensing program that yields over a billion dollars of revenue per year. Honeywell, Boeing, and many others have also profited from lucrative licensing agreements. This is a true win-win. The company that develops the technology gets to recoup some of their R&D investment and the licensee benefits from reduced time to market and access to needed technology.

One caveat before we close. Open innovation requires an investment, both in time and resources. Many companies today have what can be called “technology scouts” who spend full-time working to identify, evaluate, and develop open innovation pathways. Additionally, when I was a researcher, I had to spend time and work closely with my two university programs. If you don’t invest in resources to drive and manage open innovation, you won’t get the results you wanted.

Open innovation is a necessity in today’s fast paced markets so for your own good, find a way to embrace it and make it work for your company.

______________

1. Henry Chesbrough, “Open Innovation, the New Imperative for Creating and Profiting from Technology,” Harvard Business School Press, 2003

2. Henry Chesbrough, Open Innovation; Renewing Growth from Industrial R&D, 10th Annual Innovation Convergence, Minneapolis, Sept. 27, 2004

Leave a Reply