This is the second in the series of the Five Keys to Innovation Success. A key part of an effective innovation process is the practice of developing platforms, not single products. The automotive industry has used this approach for a long time. If you look carefully at the cruise control in Toyota automobiles, they are the same as used in the Toyota luxury line of Lexus cars. This best practice not only simplifies the supply chain, but developing platforms allows one to leverage your R&D investment over multiple products.

So how would this work for polymers? Let’s use the example of a complex polymer formulation such as an adhesive. There are many ingredients in a typical adhesive to give it the desired properties. There are the base polymer (resin) technology, reactive diluents, adhesion promoters, fillers, hardeners and catalysts, surfactants, and wetting agents. How does the formulator figure out how to put the ingredients together? There are two approaches; one is what I call formulation by “art.” In this case, the formulator gathers experience by “trial and error” and builds what I call their excel spreadsheet in their heads. If they need a little more adhesion, they add a touch of this additive, if they need a little higher modulus, the tweak the resin with a little bit more or less of an ingredient. In all of these cases, they try different combinations and test. It’s called one-factor-at-a-time (OFAT). It takes a lot of time and is hit and miss. Now, don’t get me wrong, plenty of successful products have been developed this way and for small, incremental product improvement projects this is an acceptable way to accomplish “product tweaks.” The problem is that typically there is little understanding of the science behind the formulation and if modifications are required beyond a simple tweak, then the process has to start all over again.

The second approach is what I call formulation science. To old-school formulators this is a bit of an oxymoron. Formulation science and specifically developing product platforms can significantly improve your formulation speed and efficiency. Let’s dive into how it works.

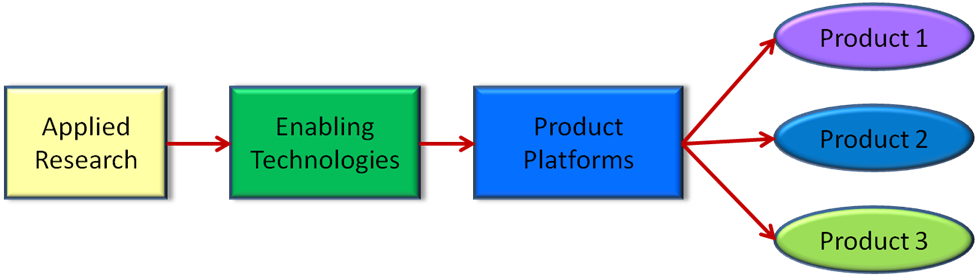

Let’s look at the figure below. It starts with applied research that is focused on addressing future customer unmet needs. This is not blue sky research, but carefully planned projects to develop enabling technologies to address customer/market problems or unmet needs.

Applied research identifies new technologies that enable the building of product platforms. Examples of enabling technologies are new base polymers (such as polyimides, acrylates, epoxies, bismaleimides, etc), new filler technologies (nanofillers or nanotubes) or filler surface treatments, conductivity promoters, reactive diluents, surfactants, and many more depending on the application. Once feasibility of the enabling technology is demonstrated, the strategic formulator is now ready to build a new product platform. So what is a strategic formulator? A strategic formulator is a very experienced but highly trained scientist who has deep understanding of the underlying chemistry and physics of the application and can leverage their science-base and an understanding of the customer need to develop a product platform. Once the product platform is completed, multiple products can easily and quickly be developed in response to customer requests. For example, for an electrically conductive adhesive platform, multiple products with different cure times can be developed by carefully changing the catalyst or hardener. In this case, the catalyst and hardener were developed as enabling technologies or were added to the product platform from the existing supply chain. In this case, the benefit of the platform approach is that you don’t have to start over to formulate a faster curing system but simply look at the available curing agents in the product platform and chose the one that will get you the right cure speed. This is analogous to the automotive platforms, where they leverage engines, suspensions, cruise controls, braking systems, etc. across multiple car platforms. In our case we are leveraging enabling technologies such as resin chemistry, fillers, reactive diluents, additives, etc. across formulation platforms.

The benefits of product platforms are:

- Reduce complexity

- Enables faster product development

- Respond to customer requests quickly

- Simplify the supply chain

- Use same suppliers or components across multiple product platforms

Many formulation companies have used a platform approach to significantly increase the impact of their R&D efforts as well as being more responsive to the customer. It takes some time to get your organization aligned and effective (as well as unwavering top management support), but in the long-term using a product platform approach will pay many dividends.

Leave a Reply