(source: iStock photo/Getty Images)

For my readers who live in the United States, the last few weeks have been a head-scratcher. One of the key campaign issues was job creation. So how do you create jobs? Interesting and complicated question. Since this is an innovation blog, one might ask, where is the topic of innovation in the discussion? My take is that it is conspicuously absent. There is a lot of discussion about the US trade policies causing significant job losses. While there is likely a component related to trade, one of the major drivers is innovation in the area of automation.

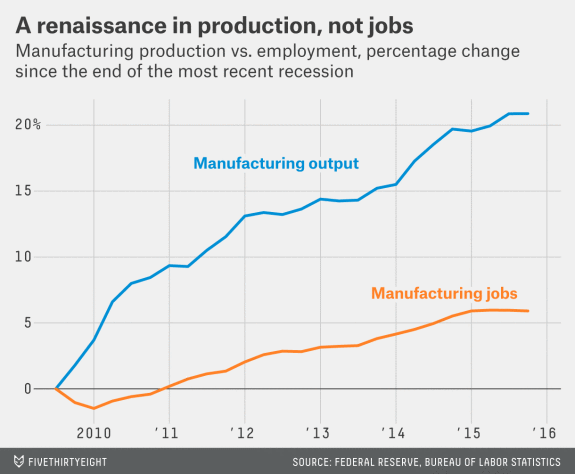

Labor costs for most products are a significant portion of the total manufacturing costs. The relentless drive to improve profits and shareholder value is a major driver in reducing manufacturing costs. It now takes significantly less workers to produce an automobile compared with several years ago. Those jobs are not coming back. Companies are investing millions of dollars to upgrade factories to enable the production of higher quality products at lower prices. This results in a win-win for both the consumer and the company. To illustrate this point, see the graph below:

After the economic downturn in 2009 the manufacturing output has grown by over 20 percent while job growth has topped just over 5 percent. What is the driver of the improved manufacturing output? Innovation in automation is one part of the reason. Improved statistical process control and design for manufacturing are also contributing factors. Another interesting thing is happening. Some US companies are bringing manufacturing back to the United States (called “onshoring”). Onshoring is a good trend, but unfortunately jobs haven’t come back in large numbers. The main drivers are innovation in the supply chain, improved manufacturing efficiency, reduced shipping costs due to being close to the customer and controlling labor costs (automation). Americans are accustomed to the low price and high quality of most consumer goods. US companies must be innovative in manufacturing to stay competitive in the global economy.

(source: iStock photo/Getty Images)

In the manufacturing sector, there will always be a need for highly skilled engineers and technicians to run and maintain a highly automated factory floor. The use of lean and statistical methods to eliminate defects and improve cycle time will continue to be effective in lowering the overall cost of goods. I have personally used statistical design tools (Design for Six Sigma or Design for Manufacturability) to develop new products with a very high process capability (much less defects and lower cost) right from the start. Add in automation to lower the cost of repetitive, low skill labor and you see the manufacturing output soar without a large increase in jobs.

One way to create jobs is to develop new products, start new companies, and provide better service to your current customers. Back to innovation. I had a project last year where InnoCentrix worked with a client to formulate several new thermoset products, designed a new manufacturing process, and scaled up to volume production. The project created not only some manufacturing jobs, but as the business expanded it created new sales positions, installers, etc. Our biggest challenge? Finding skilled workers to staff the operation. The skill gap is the biggest issue in my opinion limiting future job growth.

So what happens to those people who lost their jobs in the manufacturing sector? How do they find a new job or career? Not a simple answer, but we will discuss in a subsequent post.

Leave a Reply