In the last couple posts we discussed solving really big polymer problems and gave some examples. In the next two posts we will go into more details on a systematic approach to solving those big hairy polymer problems.

In the last couple posts we discussed solving really big polymer problems and gave some examples. In the next two posts we will go into more details on a systematic approach to solving those big hairy polymer problems.

Tough times call for bold actions. The advanced materials manufacturing sector is going through a challenging period. Take a hard look at your business. Are your customers complaining about defective products or materials that don’t meet specs? Is the cost of poor quality (scrap, rework, high inventories) cutting into your bottom line? Are your competitors gaining market share with better materials or faster delivery?

Implementing a process management approach will allow you to:

· Reduce scrap and rework allowing you to provide a low cost option for your customers

· Reduce inventory and eliminate costly non-value added manufacturing operations

· Deliver nearly defect-free products 100% of the time

· Provide shorter lead-times and guaranteed on-time delivery

· Enable your customers to be successful by providing the material performance they require

Competition in the marketplace is brutal. Price erosion is significant. Customers are demanding better service and are upset with unreliable products. Investors are looking for better business models and increased profitability. In order to increase profits, you must vigorously eliminate cost in your manufacturing operations and develop new high margin products that can gain market share.

Time for a gut check. Do you have the courage to commit some talented resources to reduce defects and eliminate non-value added manufacturing operations? This won’t be an easy task, but the failure to act is even more painful.

The Process Management Solution

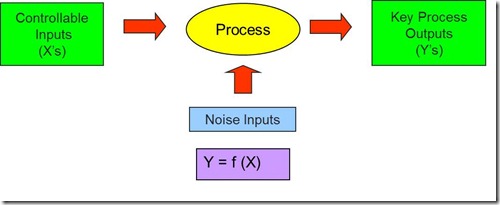

Process management tools provide solutions to complex problems. All work activities are a process whether they are in manufacturing or in the office. The process can be graphically described using a technique called a process map or flow diagram. For each individual process step or for the overall process, the key input and output variables are identified:

The controllable key process inputs are termed the X’s and the key process outputs are termed the Y’s. The outputs (Y’s) are a function of the X’s. In mathematical terms, Y = f (X). The process management approach is used to identify and improve key Y’s. The process improvement roadmap is:

1. Identify the key process outputs critical to customer satisfaction (find the key Y’s)

2. Investigate how the input variables (the X’s) impact the critical Y’s

3. Prioritize the key X’s

4. Reduce variation and control the key process inputs (the X’s)

For example, in the manufacturing of a printed circuit board, the final thickness may be a key output variable for a particular customer part. During the final lamination process, the key input variables might be layer thickness, the amount of resin to bond the layers together, the press heating rate, and lamination pressure. Design of Experiments (DOE’s) are typically used to establish how the key input variables control or influence the key output variables.

In the printed circuit board case, the heating rate and pressure have a large influence on the final part thickness. These variables can be controlled using a standard operating procedure (SOP) such as a computer controlled lamination process that is set for a given part number. The key process variables are also measured and documented in a process log or traveler that accompanies the order.

Noise variables are defined as inputs that will have an impact on the output variables, but are very difficult or very expensive to control. An example of a noise variable would be relative humidity in the vicinity of a coating process. Moisture can affect the coating process by changing the viscosity and impact the curing rate if moisture interacts with the catalyst. To control noise variables, two approaches can be used:

- Install expensive temperature/humidity controls to minimize the impact

- Use Robust Design techniques to design the material/process to be insensitive to moisture, thus alleviating the need for expensive controls

In the next post we will outline how to use Six Sigma tools as a systematic process management method for improving, building, and sustaining business performance.

Leave a Reply