In order to be a successful innovator these days you have to be fast. But how do you measure “fast?” Some of our readers may remember the Fram oil filter ads “you can pay me now or you can pay me later.” In any case, you will have to pay up. But how does that relate to innovation?

In order to be a successful innovator these days you have to be fast. But how do you measure “fast?” Some of our readers may remember the Fram oil filter ads “you can pay me now or you can pay me later.” In any case, you will have to pay up. But how does that relate to innovation?

Or a corollary with similar implications is “nobody has enough time to do it right the first time, but always has plenty of time to do it over.” This is my favorite one since how many times have you observed someone trying to be fast, sending out samples before the’re ready just because they think this will make them fast. Then how many times doesn’t it work, the customer complains and you have to do it over again. Or worse yet, you don’t find out the problem until scale-up.

So one of the key issues to wrestle in new product development is how do you know what is the right pace. Even Apple had difficulties with a faulty antenna in the iPhone 4. Where they trying to get a new phone to the market before all the bugs were worked out? How much did it actually cost them in returns and was forced to settle in a class action lawsuit.

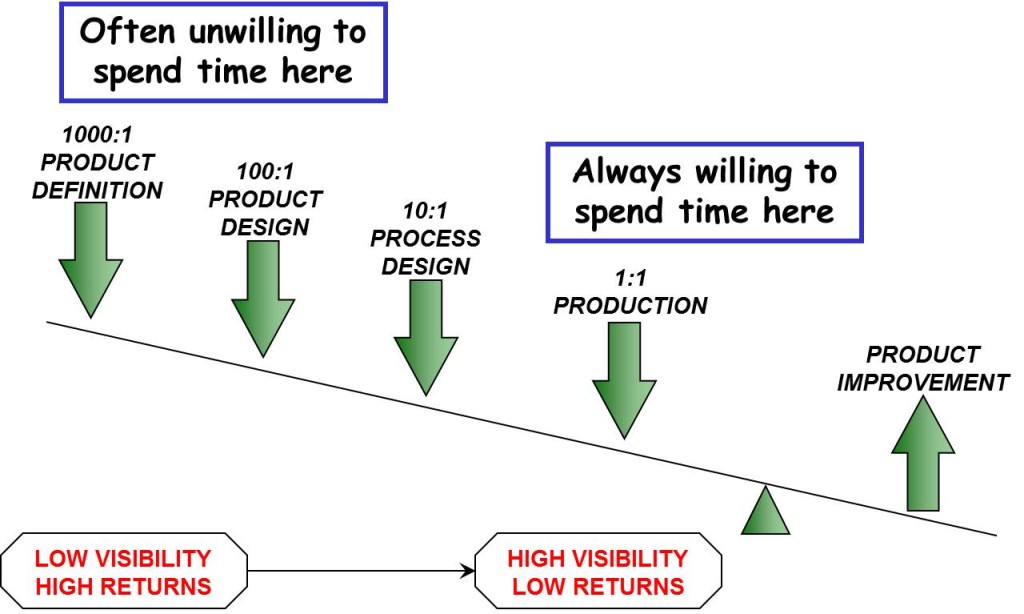

Consider the following schematic:

Many organizations are unwilling to spend the time and resources on the design phase. They think they are fast since they can get a product to the customer, but are they really faster? What would you define as the product development time? The total time to get the product right, or just out the door? While spending more time up front may take longer, the actual total product development time can be significantly shorter. And a lot less expensive. Right off the top of my head I can think of at least two situations where shortcuts were taken to get a product out the door only to cost millions of dollars once the product was in production. So why don’t more product developers see the big picture?

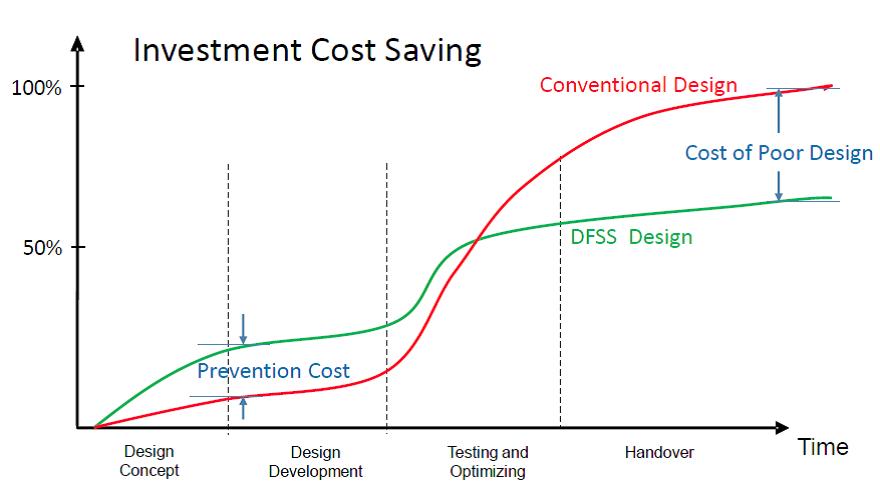

The real reason to spend more time during the design and product development is the cost savings. Remember the saying “you can pay me now or you can pay me later.” This chart demonstrates this nicely. It is always less expensive to pay upfront than to pay later when the product has been commercialized. In the figure below we can see this as the cost of poor design. This is typically a hidden cost, since in the heat of battle to fix the issue, nobody really cares how much it costs, they only want the problem fixed.

There is another benefit. You can ask why has traditional six sigma programs failed to sustain the early gains? My response is that companies that didn’t embrace Design for Six Sigma (or at least some of the concepts above) continued to introduce new products with poor quality. These then offset the product improvements in the factory. Fix an existing product, introduce a poor product. For rapidly growing companies, the product introduction is faster than they can fix existing products so the overall quality stagnates or in many cases gets worse. It’s the proverbial “trying to walk up the down escalator.”

So how do you define innovation speed?

Leave a Reply