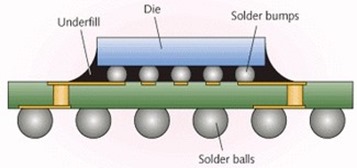

I trust everyone had a nice relaxing and safe Thanksgiving Holiday. In our last post we discussed the use of fillers to increase the thermal conductivity of thermosets. In this post we will explore how fillers can be utilized to lower the coefficient of thermal expansion (CTE) in thermosets. There are many examples of where CTE reduction is helpful and in the image on the left a good example is shown. The green substrate in the image is a plastic ball grid array (PBGA) and the die (semiconductor chip) is attached to the substrate using solder bumps. The die has a very low CTE on the order of 3 ppm/°C. The CTE of the substrate is approximately 17 ppm/°C leading to a potentially large CTE mismatch during thermal cycling. The PBGA substrate is typically a bismaleimide triazine epoxy (BT epoxy) thermoset resin impregnated with woven E-glass fiberglass fabric along with copper electrical traces. The PBGA substrate manufacturers strive to provide the lowest CTE as the price point for the particular application. In order to control the thermal fatigue of the solder bumps, an underfill material is placed under the die. In high volume manufacturing, capillary underfills are used. Most commercial underfills are filled epoxy resins formulated to achieve good flow and wetting of the die and substrate, along with achieving the required material properties after curing. Underfill material properties include a high modulus (around 10 GPa), mid-range Tg (around 90°C) and a low CTE (target around 25 ppm/°C).

I trust everyone had a nice relaxing and safe Thanksgiving Holiday. In our last post we discussed the use of fillers to increase the thermal conductivity of thermosets. In this post we will explore how fillers can be utilized to lower the coefficient of thermal expansion (CTE) in thermosets. There are many examples of where CTE reduction is helpful and in the image on the left a good example is shown. The green substrate in the image is a plastic ball grid array (PBGA) and the die (semiconductor chip) is attached to the substrate using solder bumps. The die has a very low CTE on the order of 3 ppm/°C. The CTE of the substrate is approximately 17 ppm/°C leading to a potentially large CTE mismatch during thermal cycling. The PBGA substrate is typically a bismaleimide triazine epoxy (BT epoxy) thermoset resin impregnated with woven E-glass fiberglass fabric along with copper electrical traces. The PBGA substrate manufacturers strive to provide the lowest CTE as the price point for the particular application. In order to control the thermal fatigue of the solder bumps, an underfill material is placed under the die. In high volume manufacturing, capillary underfills are used. Most commercial underfills are filled epoxy resins formulated to achieve good flow and wetting of the die and substrate, along with achieving the required material properties after curing. Underfill material properties include a high modulus (around 10 GPa), mid-range Tg (around 90°C) and a low CTE (target around 25 ppm/°C).

Let’s take a look at how fillers can be used to meet the underfill material property requirements. The CTE of unfilled cured epoxy resins ranges from 45-65 ppm/°C (ref. 1). In order to reduce the CTE into the target range, fillers are used.

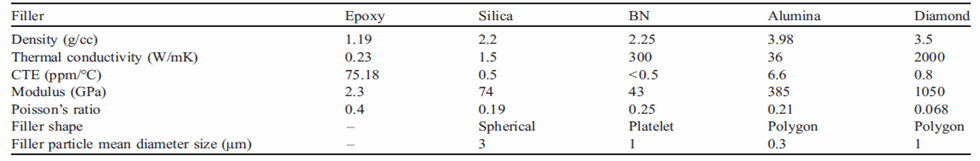

Material properties of common fillers (from ref. 2):

In the work of Lee and Wu (ref. 2), the epoxy had at slightly higher CTE of 75 ppm/°C, with the silica at 0.5 ppm/°C, boron nitride (BN) at 0.5 ppm/°C, Alumina at 6.6 ppm/°C, and diamond at 0.8 ppm/°C. In all cases, the CTE of the filler is at least an order of magnitude lower than the epoxy (or other polymeric matrix) in the composite.

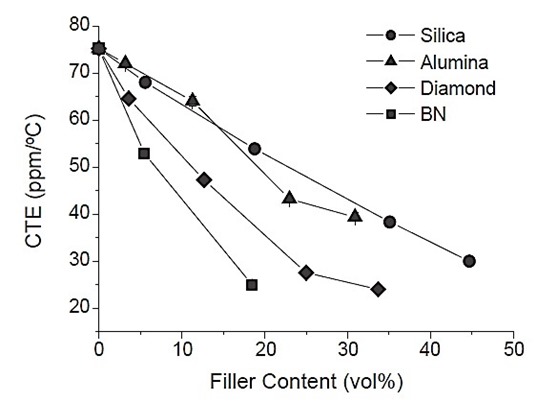

In Figure 1, the coefficient of thermal expansion is plotted as a function of volume fraction of filler loading (ref. 2).

Figure 1. CTE as a function of volume percent filler content

For each type of filler particle as the loading increases, the CTE decreases. However, the effectiveness of the fillers at reducing the CTE are not the same. As was observed in a previous post, the filler type plays an important role in the efficacy of CTE reduction. The most common and least expensive filler is silica. Recall that the aspect ratio for the silica particles is nearly 1 since the particles are spherical. Spherical particles allow for higher filler loading with a lower increase in viscosity and are commonly employed with flow and filling are important. In capillary underfills, the rheology and flow properties are critical for successful application. In the Figure 1, very high volume percent loadings of silica are required to get close to the target CTE. On the other hand, fillers with high aspect ratios such as BN provide a rapid reduction in CTE at comparatively lower filler contents. The alumina and diamond fillers have grain-like of polygon type shapes and exhibit CTE reduction which is intermediate between the silica and BN. Diamond is an effective means to reduce CTE, but is typically not used due to cost constraints in many composite applications.

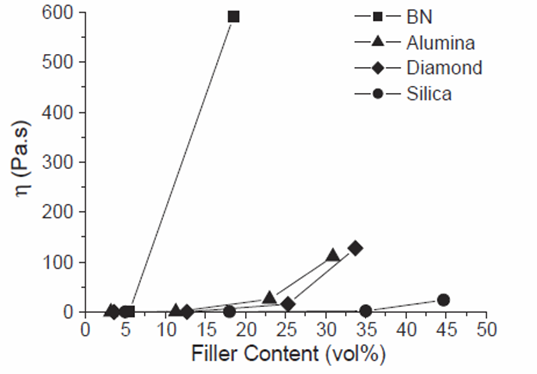

Processing is an important consideration so let’s look at the impact of the above fillers on the viscosity. In Figure 2 (ref. 2), the viscosity at 30°C is plotted as a function of filler loading:

Figure 2. Viscosity (at 30C) as a function of volume percent filler content

Consistent with the CTE data, the filler aspect ratio plays a key role in controlling the rheological properties. The high aspect ratio BN causes a very rapid increase in the viscosity as relatively low filler content. The spherical silica particles may be loaded up to 45 volume percent before any measured increase in the viscosity. As we discussed in a previous post, think about poker chips versus marbles flowing in a low viscosity medium. The spherical particles easily roll past each other while the plate-like particles with have significant interactions causing a rapid viscosity increase. As with the CTE data, the intermediate aspect ratio (polygonal) fillers exhibit a moderate increase in the viscosity in the range of 30-35 volume percent loadings.

For the material formulator, the challenge is to achieve the desired mechanical properties (in this example, CTE) while maintaining processing. Careful evaluations of the filler type and volume percent loadings are required to optimize the thermoset composite for optimal properties.

References:

- https://www.engineeringtoolbox.com/linear-expansion-coefficients-d_95.html

- Woong Sun Lee and J. Yu, Diamond and Related Materials 14, 1647 (2005).

Hi Jeff:

I’ve followed your posts on CTE and have a issue that I hope you will consider commenting on.

In making epoxy parts with various reinforcements, the mismatch between a) part being processed and b) the aluminum or steel mould causes internal stress in the part as it goes through the production cycle. As the part cools the stress is locked in which raises warpage and delamination concerns.

We have a new system that has 2 interfaces. a) part to b) composite mould and composite mould to c) support structure. The support structure is tunable so it can soften slightly after/near Tg. This means the support can move as the part cools and contracts. Question: Am I correct in assuming the part shape can be maintained by the mould faces on cooling while the molecules still shift to aleviate locked stress after Tg. How long after Tg are the molecules still mobile or when in the thermal cycle can the stress be releived so as not to be trapped permanently in the part after demould. I accept that there will be no precise answer to this general question but your expertise and experience hopefully can shed some light on this issue. I’d appreciate any comments you can make or any references that will help me in my search.

Thanks,

John