Guest Blog by Dr. Robert Humphreys

We will now change our focus a bit to look at how renewable feedstocks are used as starting materials. Dr. Humphreys is an InnoCentrix team member and has over 28 years of experience as a scientist and senior R&D manager in renewable chemicals, industrial adhesives, specialty polymers, and household and personal care products.

We will now change our focus a bit to look at how renewable feedstocks are used as starting materials. Dr. Humphreys is an InnoCentrix team member and has over 28 years of experience as a scientist and senior R&D manager in renewable chemicals, industrial adhesives, specialty polymers, and household and personal care products.

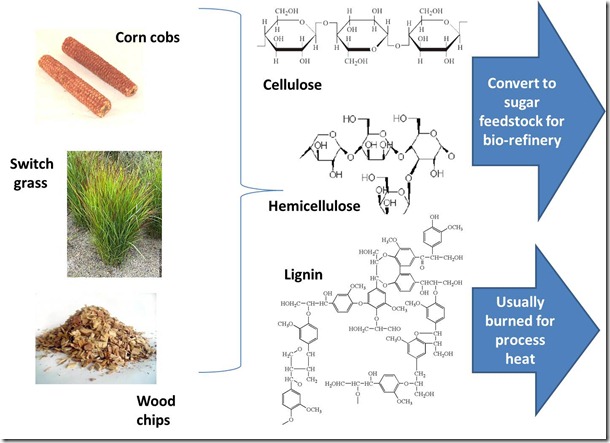

Anyone with a recently developed interest in renewable chemicals and plastics must find the vast array of information on the subject to be somewhat bewildering. Indeed, it’s not easy to imagine how wood, corn cobs and stalks, switch grass and yard clippings can be turned into a clear, plastic water bottle. In the next few postings, we will try to present a coherent picture of the technology behind this metamorphosis, maintaining a focus on producing renewable plastic bottles since this is the market that has received the most publicity. First, we will devote some time to describing what biomass is and how it will be used. Switchgrass photo above from Anna Gardner, Iowa State University.

IMPORTANT: We are talking about “Non-food” Biomass

In a world where perhaps half of the population lives on $US2/day or less and struggles to obtain adequate nutrition, use of agricultural commodities such as grains (corn, wheat, rice) to produce fuel, chemicals and plastics is deemed unacceptable. This explains the focus of the “renewables” industry on non-food biomass as preferred feedstock for fuel and chemicals. For readers who are wondering how much biomass will be required and don’t have time to read huge government white papers, 15 minutes at a TED.com presentation will provide pleasant, visual overview: (https://www.ted.com/talks/david_mackay_a_reality_check_on_renewables )

Non-food biomass includes a wide range of plant-derived materials such as wood, corn stalks and cobs, switch grass, and yard clippings, to name just a few. Some non-food biomass is currently agricultural or municipal waste (eg. corn stalks and cobs, yard clippings) while other types can be crops specifically developed for renewable fuel and chemicals production (eg. switch grass). Such biomass is mostly a structural composite of cellulose, hemicellulose and lignin in different ratios depending on plant source. Cellulose, the most abundant polysaccharide, is a stiff, very high molecular weight, water-insoluble linear polymer composed entirely of glucose, which is the same 6-carbon sugar found in food starch. Hemicellulose is a more complex polysaccharide consisting of both 5-carbon and 6-carbon sugars with the most abundant sugar being xylose, a 5-carbon sugar. Cellulose and hemicellulose can be broken down to mixtures of simple sugars and sugar oligomers using chemicals or enzymes. Lignin is not a polysaccharide but rather is a cross-linked, network polymer with many aromatic rings. Lignin can be broken down to a complex mixture of substituted aromatic ring molecules with most rings having one or more hydroxyl groups. The paper industry has perfected processes for separating these polymers from wood pulp on a huge scale.

There are several distinct approaches to converting biomass to fuel and chemicals. Some processes rely on fermentation by microorganisms such as bacteria or yeast to convert biomass to molecules that can be used as fuel or chemicals. Other processes rely on a rapid heating method called fast pyrolysis. Simple chemical conversion of biomass can also produce useful chemicals. In every case, breakdown of the raw biomass to a more process-friendly form is necessary before conversion to useful fuel and chemicals can begin. Accomplishing this breakdown in an economical way is critical for the successful commercialization of renewable fuel and chemicals and is one of the great challenges facing the renewable fuel and chemicals industry. In the next post, we will describe biomass pre-treatment and breakdown technologies as the first critical step in converting biomass to fuel and chemicals, emphasizing renewable plastic bottles as an example of the end product.

Leave a Reply