1) Bioplastics can be either biobased or biodegradable, or both depending on the type of polymer.

1) Bioplastics can be either biobased or biodegradable, or both depending on the type of polymer.

2) There are broad markets and applications for bioplastics

3) The bioplastics industry is embryonic but poised for rapid growth

Let’s take a deeper look into the field of bioplastics.

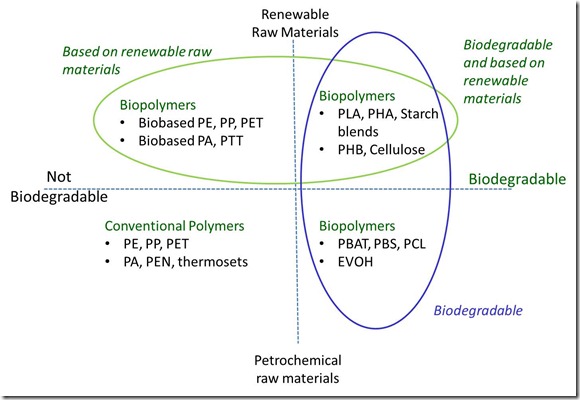

In our last post we discussed the definitions of biobased and biodegradable (compostable) plastics. So what polymers are biobased and fossil fuel based? To get a high-level view let’s look at the matrix provided by the University of Applied Science and Arts, Hannover, Germany. The two axis show the starting materials (vertical axis) and the biodegradability (horizontal axis):

There are two interesting features; the class of materials that are made from renewable starting materials (the green oval) and the class of materials that are biodegradable (the blue oval). One can easily see that biobased polymers can be either biodegradable or not biodegradable. Conversely, you can have biodegradability with both biobased and fossil fuel based polymers.

In the above graph the following abbreviations are used:

PLA; polylactic acid, PHA: polyhydroxy alkanoate, PHB; polyhydroxybutyrate, PBAT; poly(butylene adipate-co-terephthalate), PBS; poly(butylene succinate), PCL; polycaprolactone, EVOH; ethylene vinyl alcohol, PE; polyethylene, PP; polypropylene, PET; polyethylene terephthalate, PA; polyamide (nylon), PTT; poly trimethylterephthalate, PEN; polyethylene naphthalate, thermosets include various epoxies, polyimides, acyrlates, polyurethanes, and vinyl esters.

The main market driver today is the push to use renewable, biobased starting materials such as corn, sugar cane, and starch to develop “drop-in” replacements for current fossil fuel based polymers. The bio PE from Braskem and the bio PET used in the Coca-Cola PlantBottle are good examples of biobased polymers that are recycled and will drop into the existing recycling system without disrupting the quality of the recycle stream. Poly lactic acid (PLA) is gaining acceptance as a replacement for fossil fuel polymers used in cold beverage containers and flexible films for food packaging. PLA has a low glass transition temperature, around 55-60oC and thus limits its use in hot beverage applications.

Bioplastics comprise about 1% of the total plastic production worldwide, but the percentage is growing steadily due to the increasing availability of “drop in bioplastics.” Additionally, compounders have developed novel ways to improve the properties of many bioplastics, most notably, PLA. Most of the PLA in production today has been significantly improved by clever compounding procedures.

The main motivator for the bio-based chemical market is the favorable government policies. Governments of different countries are taking necessary steps which are acting as a key driver for this market. The rising government initiatives towards encouraging green chemistry & business sustainability programs such as banned plastic bags in their regions & imposing restrictions on free distribution of disposable carry bags are also contributing to the growth of the market.