In the last post we described the experimental setup for making simultaneous viscosity (dynamic complex viscosity) and dielectric measurements. In this post we will dive a bit deeper into how to use this method to probe the physical changes occurring during non-isothermal curing.

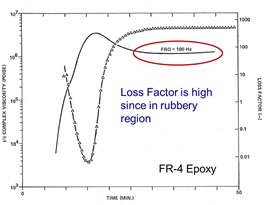

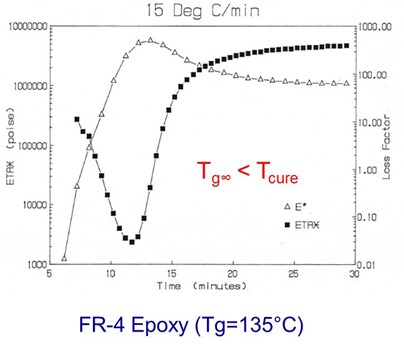

To demonstrate how the dielectric loss factor changes as a function of fully cured glass transition temperature (Tg) in relation to the cure temperature, two B-staged epoxy resins were measured in the rheometer. The first epoxy had a fully cured Tg far less than the final cure temperature. The rheometer was heated at 15oC/min. to a final cure temperature of 175oC. Once the final cure temperature of 175oC was reached, the rapid curing chemistry drove the resin system to full conversion since at the cure temperature, the resin would be in the rubbery regime. The complex viscosity attains a plateau and simultaneously, the dielectric loss factor becomes independent of time after about 25 minutes. The simultaneous complex viscosity and dielectric loss factor are shown in the following figure:

As we observed in the last post, as the temperature is ramped to the cure temperature, the B-staged resin goes through Tg and softens. One can see the large drop in the complex viscosity once the Tg is passed. With increased segmental mobility, the ionic conductivity increases rapidly as well as can be seen in the figure above. Remember the ionic conductivity is the main feature controlling the dielectric loss factor. In this case, the dielectric loss factor remains fairly high due to the ability of the chain segments to move in the rubbery regime. Also, the ionic conductivity probes only a small section of the chain and in the rubbery regime there is enough mobility to give rise to a strong ionic conductivity component.

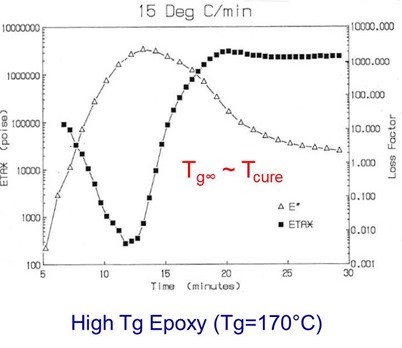

In the next figure, another B-staged epoxy resin with a Tg close to the cure temperature was examined.

In this system, the full cured Tg is 170oC and the rheometer was heated at the same heating rate as the first figure to the final cure temperature of 175oC. A few features to note. The width of the viscosity window is slightly wider for this epoxy resin and this can be observed in both the complex viscosity and dielectric loss signals. Additionally, since the fully cured Tg is very close to the cure temperature, there is a larger decrease in the dielectric loss factor since during the epoxy network (crosslinking) reaction, the segmental mobility is more constrained due to the tighter network associated with the higher Tg. One can also use the dielectric loss to determine the cure endpoint as the asymptotic approach to a zero slope between 25 to 30 minutes. It is also interesting to note that the dielectric loss factor appears to have subtle changes at long times whereas the complex viscosity has reached a plateau at earlier times.

In this system, the full cured Tg is 170oC and the rheometer was heated at the same heating rate as the first figure to the final cure temperature of 175oC. A few features to note. The width of the viscosity window is slightly wider for this epoxy resin and this can be observed in both the complex viscosity and dielectric loss signals. Additionally, since the fully cured Tg is very close to the cure temperature, there is a larger decrease in the dielectric loss factor since during the epoxy network (crosslinking) reaction, the segmental mobility is more constrained due to the tighter network associated with the higher Tg. One can also use the dielectric loss to determine the cure endpoint as the asymptotic approach to a zero slope between 25 to 30 minutes. It is also interesting to note that the dielectric loss factor appears to have subtle changes at long times whereas the complex viscosity has reached a plateau at earlier times.

The simultaneous complex viscosity and dielectric loss factor measurements have demonstrated that dielectric measurements can be a sensitive probe during thermoset curing.

The next post will continue to examine more resin systems using the simultaneous method.

Leave a Reply