Guest Post by Huan Lee, Lambient Technologies

Let’s look at the cure of carbon fiber reinforced prepreg (CFRP), which is challenging because of the conductive fabric. Use of a filter allows resin to flow to a dielectric/conductivity sensor yet prevents carbon fibers from short circuiting the measurement. In this post I’ll present data from a single batch of CFRP, tested for repeatability and effect of temperature on cure rate.

Let’s look at the cure of carbon fiber reinforced prepreg (CFRP), which is challenging because of the conductive fabric. Use of a filter allows resin to flow to a dielectric/conductivity sensor yet prevents carbon fibers from short circuiting the measurement. In this post I’ll present data from a single batch of CFRP, tested for repeatability and effect of temperature on cure rate.

Procedure

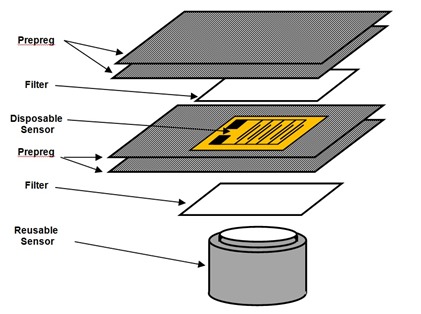

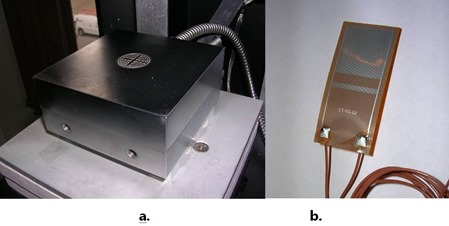

Samples were studied with a reusable ceramic sensor embedded in the lower platen of a press, as shown in Figure 1.a. A sheet of laboratory grade filter paper was placed on top of the sensor and two plys of CFRP were placed on top of the filter paper.

To compare results from different types of sensors, the ceramic sensor measured dielectric properties at the surface of the CFRP and the reusable flex circuit sensor of Figure 1.b. measured between plys of the same prepreg.

Figure 1. Reusable ceramic sensor (a) and disposable Kapton® sensor (b)

As with the ceramic sensor, the flex circuit sensor had a layer of filter paper on top of the electrodes. The lay-up with both sensors is illustrated in Figure 2. During each test the press applied heat and pressure to the prepreg, which caused the epoxy to melt and flow through the filter paper to the sensors.

Figure 2. Lay-up of reusable and disposable sensors

Figure 2. Lay-up of reusable and disposable sensors

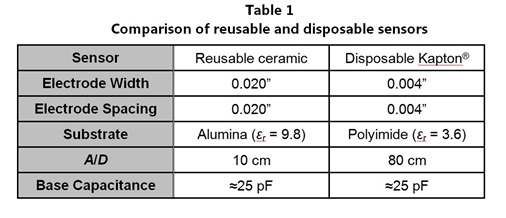

The ceramic and flex circuit sensors have very different constructions and geometries. Parameters of the two sensors are listed in Table 1:

Note that the ceramic sensor has an A/D = 10 cm compared to the flex circuit sensor with an A/D = 80 cm. As a result the ceramic sensor has only 1/8th the sensitivity of the flex circuit sensor.

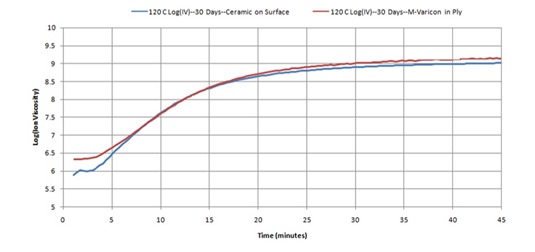

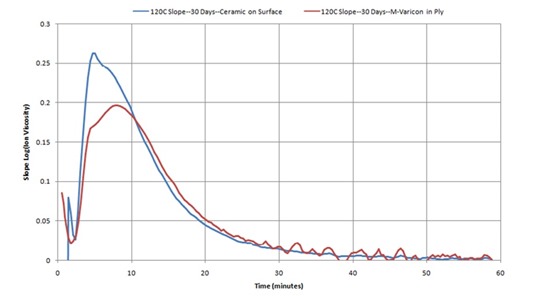

Figure 3 shows log(ion viscosity) and Figure 4 shows slope of log(ion viscosity) for the two sensors, measured using a 100 Hz excitation. For brevity, log(ion viscosity) will be called log(IV) and the slope of log(ion viscosity) will simply be called slope.

Figure 3. Lof (IV) data for ceramic sensor (blue) and flex circuit sensors (red)

Figure 4. Slope data for ceramic sensor (blue) and flex circuit sensors (red)

The ion viscosity curves overlap almost completely after about seven minutes, indicating essentially the same cure rate on the surface and within the plys. Before this time, the flex circuit sensor showed both higher ion viscosity and lower slope (slower reaction rate) than the ceramic sensor. Heat takes time to penetrate layers of prepreg to reach the disposable sensor in the middle, so material away from the platens is a little cooler than at the surface and takes a little more time to start curing. Figures 3 and 4 show that with the correct A/D ratio, different sensors provide the same cure data and are interchangeable for measuring ion viscosity.

Repeatibility of measurements

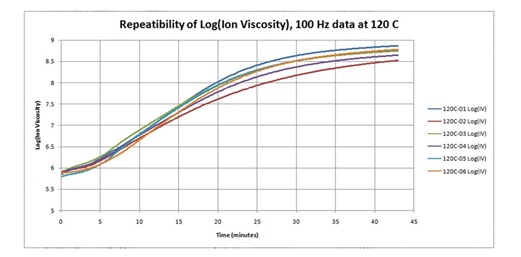

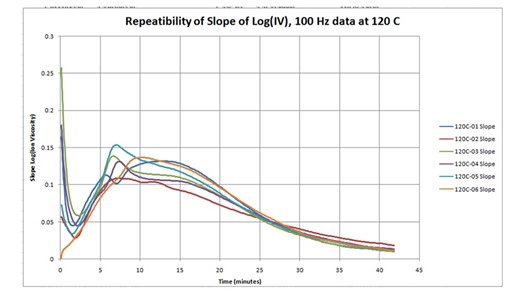

Figures 5 and 6 show log(IV) and slope curves from six tests of CFRP with the reusable ceramic sensor. Note how ion viscosity is almost the same for all tests in the beginning but has some spread at the end. This divergence is likely caused by variations in reaction rate, possibly due to slight differences in temperature from test to test.

Figure 5. Log (IV) for cures of six samples of CFRP

Figure 5. Log (IV) for cures of six samples of CFRP

Figure 6. Slope from cures of six samples of CFRP

Effect of process temperature on cure rate

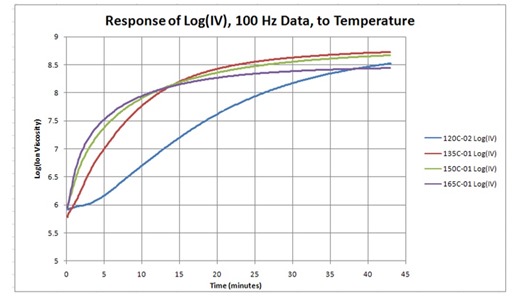

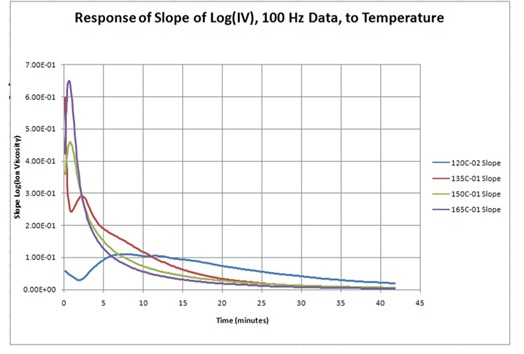

Figure 7 overlays log(IV) data for CFRP cures at 120 °C, 135 °C, 150 °C and 165 °C. Figure 8 overlays slope data for these cures. As expected, higher processing temperatures result in higher reaction rates (greater values of slope) and faster cures.

Figure 7. Log (IV) curves from isothermal cures at different temperatures

Figure 8, Slope curves from isothermal cures at different temperatures

Conclusion

Critical Points, described in my earlier posts, can characterize these ion viscosity curves and quantify how cure rate varies with temperature. Dielectric cure monitoring is unique among thermal analysis techniques because it acquires information about the entire cure during a single test, providing insights about the material and its reaction very quickly. Furthermore, dielectric cure monitoring can be used in the R&D laboratory as well as in quality control and manufacturing applications.

In my next post—the last in this guest series—I’ll provide some guidelines and simple “do’s and don’ts” about the use of dielectric sensors and dielectric cure monitoring.

Lambient Technologies

209 Newbury Street, 3rd Floor

Boston, MA 02116

617-266-2837

email: info@lambient.com

Leave a Reply