A question that often arises when looking at technical data sheets is what is the difference between the glass transition temperature (Tg) and the heat deflection (or heat distortion) temperature (HDT). To be clear, they are not the same and there is some confusion around the comparison. Many factors can influence the HDT. Let’s first begin by describing the heat deflection temperature test. The HDT is defined by ASTM D648, “Standard Test Method for Deflection Temperature of Plastics Under Flexural Load in the Edgewise Position”.

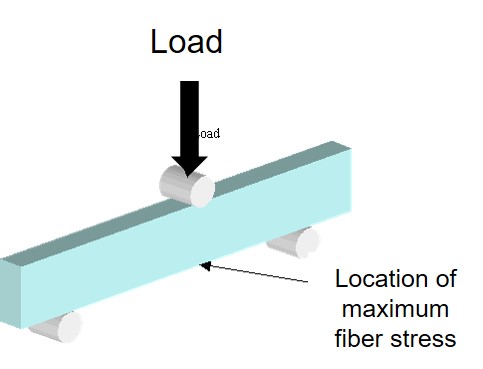

The HDT test determines the temperature where the material under test deforms 0.25 mm (0.010 inch) under load in a three point bending geometry.

Figure 1. Loading geometry for ASTM D648 heat deflection temperature test

The load is calculated so that the specimen can be subjected to a fiber stress of:

- 0.455 MPa (66 psi)

- 1.82 MPa (264 psi)

The sample as seen in Figure 1, the sample is loaded edge-wise. The details of calculating the required load as a function of sample dimensions is given in equation 1 in ASTM D648. The span length is the distance between the two supports on the bottom side of the sample in Figure 1. Two span lengths can be used and the span length changes slightly depending on the method:

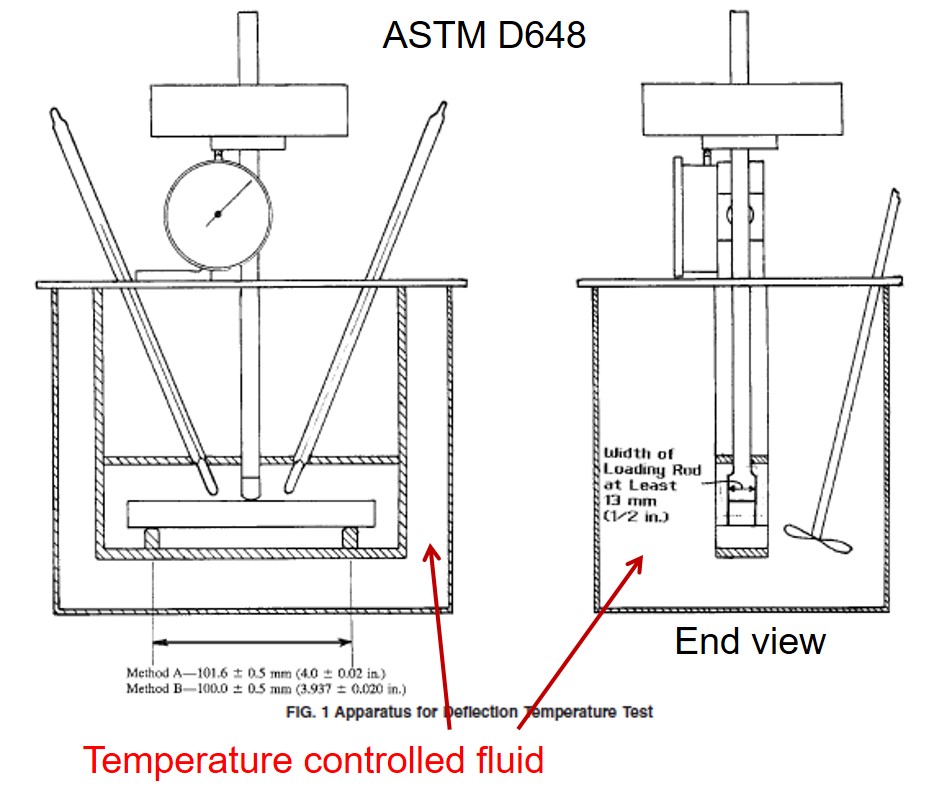

- Method A – 101.6 ± 0.5 mm (4.0 ± 0.02 in.)

- Method B – 100.0 ± 0.5 mm (3.937 ± 0.02 in.)

The test specimens are 127 mm (5 in.) in length, 13 mm (0.5 in.) in depth and can have any width from 3 mm (1/8 in.) to 13 mm (0.5 in.). The thicker specimens (approaching 13 mm) can have HDT’s from 2-4°C higher due to poor heat transfer through the samples. Recommended thickness is in the range of 3-4 mm. Care should be exercised to ensure sample uniformity. It is recommended to use at least two samples when determining the HDT for a given material or composite.

Figure 2. ASTM D648 test apparatus

As shown in Figure 2, the sample bar is immersed in a temperature controlled heat transfer medium that can be heated uniformly at 2 ± 0.2°C/minute. The liquid heat-transfer medium is chosen that will not affect the specimen. Typical fluids are mineral oil for up to 115°C and silicone oils for temperatures up to 260°C. These two fluids will cover most of the HDT’s for typical thermosets. After the sample and bath have equilibrated, the required load is applied, the heat-transfer medium heated at 2 ± 0.2°C/minute and the temperature is monitored using a digital measurement system (thermocouple or resistance thermometer). The deflection of the sample is measured using either a dial indicator or LVDT.

The heat deflection temperature (HDT) is determined when the bar deflects 0.25 mm (0.010 in). Run at least two samples and report the average temperature when the 0.25 mm deflection occurred. When presenting HDT data, note the stress level used in the test.

The next post will discuss how the specimen composition such as fiber loading and fiber direction can influence the HDT. Comparisons with the glass transition temperatures will also be given.

Leave a Reply