Characterizing thermosetting polymers poses an interesting challenge to the thermal analyst. Many processing applications require the polymer to flow into a mold or consolidate during lamination, and concurrently undergo a chemical reaction to develop a fully cross-linked network. Because of the complexity of thermosetting polymer processing, the ability to understand the changing material properties during processing is required. The technique described here allows;

Characterizing thermosetting polymers poses an interesting challenge to the thermal analyst. Many processing applications require the polymer to flow into a mold or consolidate during lamination, and concurrently undergo a chemical reaction to develop a fully cross-linked network. Because of the complexity of thermosetting polymer processing, the ability to understand the changing material properties during processing is required. The technique described here allows;

- Characterize the curing of a reactive polymer using differential scanning calorimetry (DSC) and oscillatory parallel plate rheometry

- Measure the viscosity, the glass transition temperature (Tg), and the conversion during either isothermal or non-isothermal curing conditions.

- Measure the viscosity and the dielectric loss factor during either isothermal or non-isothermal curing conditions.

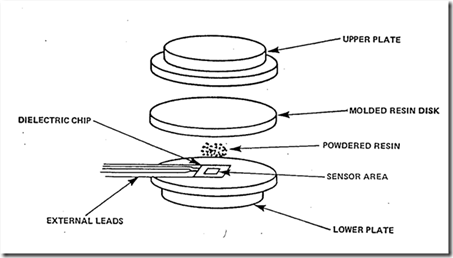

A simple modification of a parallel plate rheometer allows the thermal analyst to study the chemorheology of a curing resin system (1). Commercial rheometers can easily be outfitted with disposable aluminum plates to aid in the separation of the fixtures after the sample has cured. The use of disposable plates allows a small disposable dielectric sensor to be embedded in the lower plate, thus permitting dielectric data to be obtained simultaneously with viscosity data (2).

Experimental Description

Rheological experiments were conducted using a Rheometrics System Four rheometer with a forced-convection nitrogen purged oven. The experiments were performed in the oscillatory parallel plate geometry. Measurements were made every 30 seconds with a 2% strain amplitude at a frequency of 6.3 radians/sec (1Hz). The bottom plate was machined to accommodate a thermocouple (allowing direct measurement of the sample temperature) and a disposable dielectric sensor (Micromet Instruments).

Disposable plates with only the embedded thermocouple were used to study the relationship between the conversion, Tg, and the viscosity. Nonisothermal experiments were conducted by equilibrating the sample at 30o C and heating the sample at various heating rates to a final temperature of 175o C. At specified time intervals, the experiment was stopped, the oven opened, the disposable plates were quickly unclamped, and both the plates/sample were quenched in liquid nitrogen, stopping the chemical reaction. Thermal analysis can be performed on the quenched samples using a wide variety of commercially available DSC modules.

To correlate the viscosity and dielectric properties during curing, a disposable sensor was placed in a machined slot in the lower disposable plate. Additionally, a small slot was machined to accommodate a thermocouple. The non-isothermal rheometer runs were made in a similar manner as described above. To ensure good coverage of the interdigitated comb electrodes in the dielectric sensor, a small amount of powdered resin (at the same extent of reaction as the sample) was placed over the sensor area prior to placing the molded sample disk between the plates in the rheometer. The sample was pre-molded using a 2.54 diameter compression molding device. Powdered resin could be compacted into a solid disk without changing the degree of advancement using careful molding conditions (need to be determined for each type of resin or prepreg used in the experiments). The experimental set-up is schematically shown in Figure 1.

In the next post we will present data from non-isothermal curing studies that will demonstrate the correlation of the viscosity with the glass transition temperature (Tg) and the degree of conversion.

Leave a Reply