In the last post we talked about isothermal cure rheology. This is a good way to look at the curing time, gelation time, and get an understanding of the viscosity temperature dependence, but most commercial thermoset processing methods are non-isothermal. Whether it is bulk molding compound (BMC) molding, prepreg lamination for composites, or integrated circuit encapsulation ... [Click to Continue...]

Rheology of Thermosets Part 4: Isothermal Curing

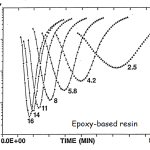

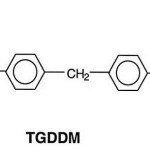

Isothermal curing can be investigated nicely using oscillatory parallel plate rheometry. It is suggested that disposable plates be used to facilitate sample removal from the rheometer at the conclusion of the curing run. When setting up the rheometer, the strain amplitude needs to be determined. In most cases, a strain amplitude in the range of 0.1-0.3% is adequate to get ... [Click to Continue...]

Rheology of Thermosets Part 3: Controlled Strain Measurements

Thermoset rheological characterization is typically done using controlled strain experiments. We discussed this in the Dynamic Mechanical posts in the characterization series. For rheometry, we use a rotational shear geometry so we are reporting the dynamic loss modulus as G” and the dynamic storage modulus as G’. As discussed in the previous post, the most common geometry ... [Click to Continue...]

Rheology of Thermosets Part 2: Rheometers

This post will cover the types of rheological measurements available for characterizing thermosets. Rheology is important in two aspects of thermoset processing. The first is during the application or dispensing of the uncured thermoset (for example an highly filled adhesive or coating) and the second is characterizing the viscosity changes during the curing process. In the ... [Click to Continue...]

Rheology of Thermosets Part 1: Introduction to Rheology Measurements

First a few background concepts to get us started. Rheology is the science of deformation and flow of matter under controlled testing conditions. Rheological testing is a powerful way to probe the structure-property-processing relationships in many types of polymers. The viscosity-shear rate profile is important in the processing of thermoplastics (like injection molding and ... [Click to Continue...]