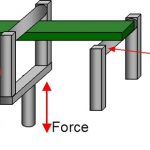

Dynamic Mechanical Analysis (DMA) is a powerful technique to measure the mechanical properties over a wide temperature range. Commercially available DMA equipment are available with cooling units to enable temperature ramps from sub ambient temperatures to high temperatures. From DMA measurements the modulus as a function of temperature is determined. From the DMA run, both ... [Click to Continue...]

Practical Tips for Curing Thermosets Part Seven: The Glass Transition Temperature Measured Using TMA

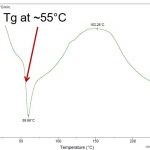

In our last post, the glass transition temperature (Tg) was shown to be a very good indicator of the degree of cure for thermosets. In several posts in this series the use of differential scanning calorimetry (DSC) was presented as an easy and reliable method for measuring Tg at various states of cure. DSC has an advantage in that the experimental method requires very small ... [Click to Continue...]

Practical Tips for Curing Thermosets Part Six: The Glass Transition Temperature is Your Friend

In the last post we started our discussion of how to monitor thermoset curing during processing and showed that the glass transition temperature (Tg) is a potential physical property that is useful for cure monitoring. A common and easy way to measure Tg is using differential scanning calorimetry (DSC), but there are other analytical methods to determine Tg. First, let’s look ... [Click to Continue...]

Practical Tips for Curing Thermosets Part Five: How to Characterize Thermosets During Curing

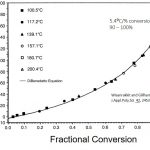

In the last few posts we have been talking about the curing of thermoset resins. For a wide variety of products, ensuring the cure process is well characterized is key. As we know, thermosets typically start as small molecules (monomers and oligomers) to allow ease of processing for applications such as adhesives, composites, laminates, and coatings. Once the curing ... [Click to Continue...]

Practical Tips for Curing Thermosets Part Four: What is the Cause of the Enthalpy Relaxation Peak on the DSC Curve and What Does it Mean?

Guest Post by Dr. R. Bruce Prime As we have described before, differential scanning calorimetry or DSC is the most widely used analytical technique to characterize thermoset cure, due its ability to quickly and accurately measure the glass transition temperature Tg and conversion or degree of cure. Tg is the temperature where on heating the thermoset changes from a rigid ... [Click to Continue...]