The previous post covered an introduction to cyanate ester thermosetting resins. This post will discuss the main applications of cyanate ester thermosets. In the 1980’s the main applications for cyanate esters were in electronic applications. Specifically, cyanate esters were used in high performance circuit boards and semiconductor substrates. The substrate technical drivers are:

- Lower coefficient of thermal expansion (CTE), specifically low z-axis expansion

- Low dielectric constant (Dk < 4) and low dissipation factor (Df< 0.01) over a wide frequency band

- Adhesion to low Dk/Df resins

- Thinner cores that enable smaller vias for high density routing

- Low warpage for thin flat substrates

The primary substrate core supplier is Mitsubishi Gas Chemical (MGC) and has supplied the industry with bismaleimide triazine (BT) laminates since the early 1980’s. MGC BT is a proprietary blend of bismaleimide, cyanate ester (triazine) and epoxy [1]. MGC provides a wide range of copper clad laminates (CCL) and prepregs. The CCL HL832NX (laminate) and GHPL-830NX (prepreg) are the standard halogen-free BT with a flammability rating of UL94V-0. Click for a complete listing of the MGC BT product offerings.

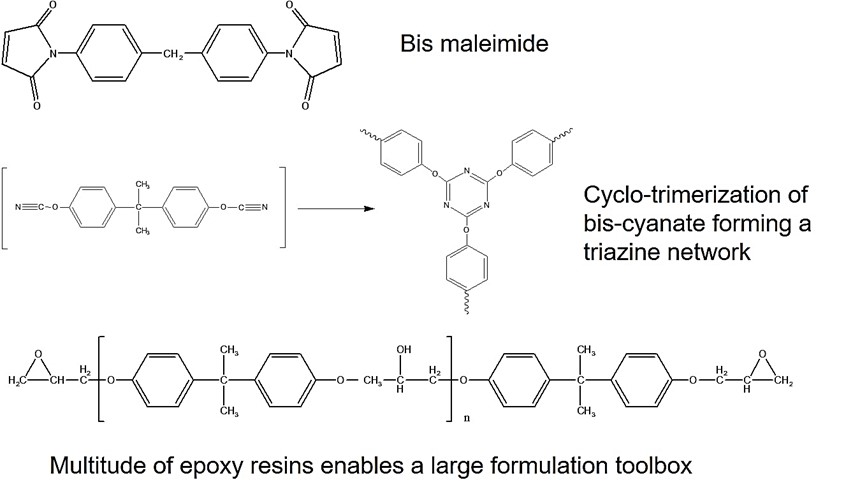

The chemistry of the bismaleimide triazine (BT) resin is shown in Figure 1.

Figure 1. Chemical components of MGC BT resin systems [1].

In Figure 1, the chemical structures are given for the three main components of BT laminates are prepregs. Owing to the high glass transition temperatures for the fully cured BT laminates, aromatic bismaleimides were used as shown in the top image. The MGC patent describes a large variety of bismaleimides that can be used. Cyanate esters are interesting in that they have very low dielectric constant and more importantly have a low dielectric loss factor. The cyanate functionality undergoes a cyclotrimerization reaction leading to a triazine ring structure. The most common cyanate ester is synthesized from bisphenol A to form the aromatic monomer. After trimerization, a very high Tg is obtained.

The third component of the BT resin system is epoxy. Epoxy monomers are available in various monomeric forms, from liquid epoxies to novolac epoxies, to the common Bis-A epoxy (as shown in the bottom in Figure 1). Epoxies are also available in several molecular weights. The curing package for epoxies is typically diamines. It turns out that diamines are also useful curing agents for the bismaleimides via the Michael addition reaction to the bismaleimide double bonds.

The MGC patent [1] also describes various amines that can be useful in tailoring the physical properties of the BT resin system. In the ‘MGC patent, example 11 shows a typical BT formulation with 10 parts by weight bismaleimide, 20 parts by weight cyanate ester and 70 parts by weight epoxy (DER 542) and 3 parts by weight of an amine curing agent, 2-ethyl-4-methylimidazole (24EMI).

Cyanate esters have found applications in aerospace due to their low loss properties. Cured cyanate esters have dielectric loss factors in the range of 0.008. The use of low dielectric loss factor quartz fibers enables aircraft radomes [2] as shown in Figure 2 below.

Figure 2. Low dielectric loss cyanate esters used with quartz fibers in an aerospace radome application [2].

Cyanate esters are used in a wide variety of applications owing to the large toolbox of monomers, oligomers, curing agents, accelerators available to the formulator. As seen in this series of posts, a large majority of commercially viable products are blends of the various types of bismaleimides and cyanate esters. The formulator’s task is to evaluate the physical properties required and then tailor the chemistry and curing reactions to achieve the desired products.

References

- US Patent 4,110,364, Morio Gaku et. al.

- Cyanate esters for radomes

Leave a Reply