Guest post by Jeremy Pasatta, Advanced Polymer Coatings

Thermosets such as epoxies, vinyl esters, cyanate esters, and benzoxazines give excellent properties such as chemical and thermal resistance, dimensional stability, high modulus and good adhesion to a variety of substrates. These properties are in part due to the crosslink density of the thermoset, where in general the higher the crosslink density, the higher the stated attributes of the thermoset. Unfortunately, higher crosslink density also makes thermosets extremely brittle, making them prone to premature fracture and failure. This brittleness, however, can be overcome through either the use of a toughener or flexibilizer. The addition of a toughener improves the fracture properties and brittleness of the thermoset while still maintaining the properties of the matrix resin such as modulus and glass transition temperature. Normally, these tougheners form a secondary domain with the primary matrix phase. The secondary phase can either be preformed, form during curing through reaction induced phase separation, or form by self-segregation. Tougheners should not be confused with flexibilizers. Flexibilizers will improve fracture properties and brittleness but do so with a reduction in matrix properties such as modulus and glass transition temperature. This is done by either reducing crosslink density or through the introduction of a more flexible structure between crosslinks. The most common types of tougheners used in thermosets include:

- Reactive liquid polymers (RLP)

- Coreshell particles

- Block copolymers

- High temperature thermoplastics

- Phenoxy resins

- Hard particles such as nanosilica, carbon nanotubes and graphene platelets

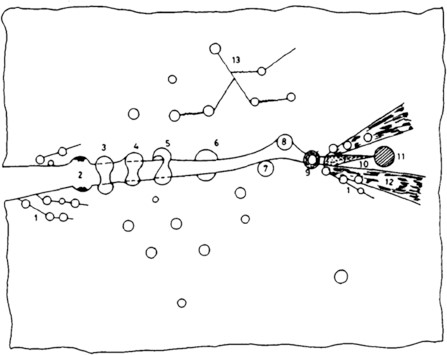

Tougheners in general operate through the introduction of a second phase particle into the primary matrix phase. The size of the secondary phase is anywhere from 10 nm to 1,000 nm (1 um). Figure 1 shows the primary modes of toughening with second phase particles.

Figure 1. Toughening Mechanisms with Second Phase Particles (from ref [1])

Figure 1 shows the various mechanisms of toughening in a thermoset using a second phase particle. The diagram shows a crack propagating through the thermoset, and the most significant contribution to toughening is shown ahead of the crack tip in regions 10, 11 and 12. In these regions, the stresses on the low modulus particles cause them to cavitate or form holes, which then grow, and enhance plastic deformation ahead of the crack tip. For hard particles that do not cavitate, matrix debonding in the primary mechanism to form voids. Other mechanisms of toughening are shown as well, including rubber bridging of the crack (3,4,5), crack deflection (7, 8) crack bifurcation (1) and particle crazing and shear banding (13). All these mechanisms combined contributed to the overall improved fracture toughness of a thermoset using a second phase toughener

Second phase tougheners are usually a low modulus, low Tg rubber. As a crack tip initiates, ahead of the crack tip triaxial stresses are placed on the rubber particles, which causes them to cavitate and form holes within the cured matrix. As stress is continually placed on these holes in the cured matrix, they dilate and grow in size, which enhances the plastic deformation of the cured matrix. This gives a high yield zone with enhanced plastic deformation ahead of the crack tip and dissipates the energy of the growing crack. There are several other mechanisms that contribute to toughening such as rubber bridging, shear banding and crack deflection, but the main mechanism of toughening is through enhanced plastic deformation of the cured matrix caused by hole dilation. For hard particles, instead of particle cavitation, the particles will debond from the matrix thereby creating holes which can then dilate and grow in size and enhance plastic deformation.

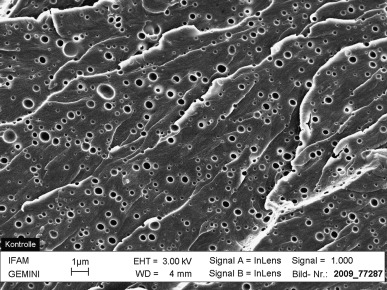

Figure 2 shows an SEM that demonstrates a typical morphology for an epoxy that is modified with coreshell resin. The SEM shows domain size of approximately 0.25 to 1 µm, which tends to be the optimal particle size for toughening with soft particles.

Figure 2. SEM of Epoxy Modified with Coreshell Resin (from ref [2]).

There are several types of applications in which thermosets are used that require an increase in toughening while maintaining matrix properties including:

- Structural adhesives, particularly one component epoxies

- High performance composites

- Potting compounds that undergo thermal cycling

- Thermosets being used at cryogenic temperatures

- Coatings that experience damage due to impact

The use of tougheners in these formulations usually does not strictly increase toughness without negatively affecting formulation properties in some other way, whether it be an increase in formulation viscosity, slight decrease in matrix Tg and modulus, or additional processing and dispersion steps. The upcoming series of blog posts will explore each toughening technology in further details, illustrating how they work, the different types of products available, typical markets and applications they are used in along with how they both positively and negatively affect thermoset properties.

References

- Xu, Shi-Ai; Song, Xiao-Xue (2015), Parameswaranpillai, Jyotishkumar; Hameed, Nishar; Pionteck, Jürgen; Woo, Eamor M. (eds.), “Introduction to Rubber toughened Epoxy Polymers”, Handbook of Epoxy Blends, Cham: Springer International Publishing, pp. 1–26, doi:10.1007/978-3-319-18158-5_1-1, ISBN 978-3-319-18158-5

- Polymer, Volume 54, Issue 18, 16 August 2013, Pages 4790-4797

Please explain your figure 1 diagram?

The post has been updated to include a more detailed description of the mechanisms shown in Figure 1. Thanks for your comment.