Or Debunking the Myths of Design for Six Sigma

We have been discussing how to use a formulation science approach to build product architectures by making sure our applied research efforts are developing the right technology platforms. Critical stuff. But what happens when you have completed the technology platforms and need to leverage them to build product architectures?

One of the myths I want to address right now is that using Design for Six Sigma (DFSS) tools does not replace the need to have highly skilled chemists who really understand the underlying chemistry. The tools we will discuss are just that: tools to help leverage the chemistry in a systematic way to achieve the desired product attributes. Traditional formulation chemists are highly skilled “executive chefs” when it comes to how they formulate a new product. They have years of experience in the “excel spreadsheet in their head” and have an intuition on how to tailor the various ingredients in order to get the right performance. But, formulations and the technical requirements are getting pretty demanding for the standard “one factor at a time” or OFAT approach to be both effective and timely. So what is the alternative?

DFSS has a number of design tools that can improve both the development time and quality.

- Voice of the Customer or CTQ trees

- Failure Mode and Effects Analysis (FMEA) used in the design phase

- Factorial Design of Experiments (DOE)

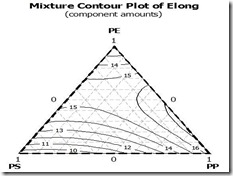

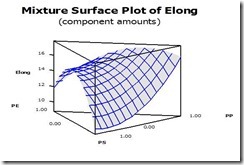

- Mixture Design of Experiments (Contour plots like above and response surface analysis below)

Chemists are great at having an “gut feel” for the main effects of most of the ingredients in a formulation (add a little more catalyst to get faster cure speed, a little more long chain oligomer to lower modulus, etc.), but it is very difficult to predict interactions. The beauty of DOE is that using statistical designs you can gain a much deeper understanding of the chemistry causing both main effects and interactions, along with getting much more robust information of how the formulation space relates to final performance.

The mixture DOE is a very valuable tool in the formulators toolbox. One way to look at the results of a mixture DOE is to use response surfaces. The mixture response surface plot on the left clearly shows how a particular physical response is a function of the composition in three dimensional space. In the example on the left, if you wanted to maximize the polymer elongation, you would want to optimize your composition at the maximum and then along the ridge at the maximum. But let’s say you were doing only OFAT experiments and you picked points on either side of the maximum. You would erroneously conclude there is no effect, but the response surface analysis clearly shows that elongation has a complex response surface. Herein lies the beauty of mixture DOE’s. Exploiting response surface methodology in formulation science is a key enabler to reduce product development time and increase the robustness of the final formulated products. By completing a series of optimization mixture designs, the formulator will learn more about the chemistry, develop a better product, and reduce time to market with improved profitability. This stuff really works!

Leave a Reply