So far this dispersion series has covered single shaft dispersers with cowles blades, multi-shaft dispersers, and double planetary mixers. This post will cover two types of hybrid planetary mixers:

- Powermix

- Planetary Dual Disperser Mixer (PDDM)

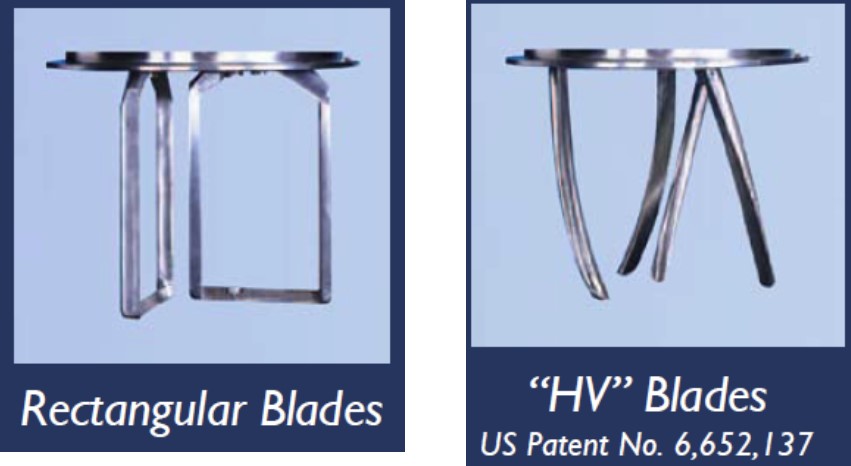

The unique feature of hybrid planetary mixers is the combination of at least one high speed dispersing blade and a slower speed planetary stirring blade. Hybrid planetary mixers are very versatile and can be used to disperse fine particles over a wide viscosity range (100,000 to 2 million cP [1]). The intense mixing action is applied by using the slower speed rectangular or helical planetary blade to move material into the high-speed dispersing blade (or blades) as they move through the mixing vessel. The unique feature of the hybrid planetary mixers is the ability to fine tune the dispersion quality since both the speed of the planetary mixing blades and the speed of the dispersion blades can be controlled independently [2].

Figure 1 shows one configuration of the Powermix from Ross.

Figure 1. Powermix with rectangular blade, two cowles blades for dispersion and an optional wiper blade (source: Charles Ross & Son Company)

The Powermix has a single rectangular blade and a shaft with a dispersing (cowles) blade. The rectangular blade functions like one of the blades in a double planetary mixer in that it helps to move material off the mixing vessel sidewall towards the center. The rectangular blade moves at a relatively low speed. The second shaft is used for high speed dispersion and orbits the mixing vessel on the same trajectory as the rectangular blade. The dispersion shaft can have a single or dual cowles blades depending on the level of dispersion required and the material turn-over during mixing. As discussed in previous post, the cowles blade is typically run at fairly high tip speeds (1,800-6,000 ft/min) to provide high shear dispersion.

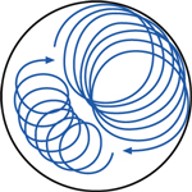

Figure 2. Powermix blade motion (source: Charles Ross & Son Company)

In Figure 2, the larger circles represent the trajectory of the slower speed rectangular planetary blade and the smaller circles represent the trajectory of the high-speed cowles blade. Note that the planetary blade sweeps along the vessel sidewall and facilitates moving material into the high-speed dispersion blade. For high viscosity mixtures, the HV blade may be used instead of the rectangular blade. As shown in Figure 1, an optional wiper blade can be used in the Powermix if more efficient heat transfer is required. The wiper blade is effective at removing material at the vessel wall and working with the low speed planetary blades to move material into the high-speed cowles blades.

The planetary dual disperser mixer (PDDM) is my personal favorite mixer. I have extensive experience using the PDDM with HV blades for dispersing a variety of fillers into thermoset resins. The PDDM has dual planetary mixing blades and duel high-speed dispersing blades. Figure 3 shows one type of blade configuration for a PDDM.

Figure 3. Planetary dual disperser mixer (PDDM) with HV helical blades and cowles blades on the high-speed disperser shafts. Note the wiper blade in this configuration. (source: Charles Ross & Son Company)

In Figure 3, the HV design is used for the two slow-speed planetary blades and the high-speed shafts have two cowles blades. In addition, the configuration in Figure 3 also includes a wiper blade to move material off the wall and into the planetary blades.

The reason I like the PDDM is the ability to fine tune the dispersion process over a large viscosity range:

- The low-speed planetary blades can be used to mix the resin components prior to filler addition (As discussed previously, order of addition should be carefully evaluated)

- Flexibility in controlling the mixing with the low-speed planetary blades

- HV blades provide rapid incorporation of fillers and efficiently move material (i.e. fillers and additives) into the cowles blades

- Flexibility in using multiple blade configurations (single and dual cowles blades on the two high-speed shafts)

- Ability to tailor the dispersion quality with the independently controlled high-speed cowles blades facilitates dispersion of multiple filler types

The ability to independently control the HV blades and the dispersing blades is the key advantage of the PDDM. For example, when mixing a combination of fillers, say a metal filler and a silica filler the tip speed required for proper dispersion may differ from one filler to another. A good example would be a product where a metal filler such as silver or aluminum and a viscosity modifier such as fumed silica are both used in the final product. The dispersion speed for the two distinct types of fillers is likely different. In this case, the fumed silica is typically the last filler added last since the tip speed is critical to achieve adequate dispersion. This example again points to the critical need to perform careful order of addition experiments during the product scale-up process. Note: Remember that in the case of premixed and frozen formulations, the hardeners and catalysts are typically added last, since work life starts with the addition of the curing package.

The PDDM is available with vacuum capability, which is required for mixing of highly-filled resin formulations. Temperature controlled (jacketed) mixing vessels are also available if temperature control during intense mixing is required.

Figure 4. Planetary dual disperser mixer (PDDM-4). (source: Charles Ross & Son Company)

The unit in Figure 4 is equipped with two HV helical planetary blades, one of which includes a bottom scarper, two cowles blades installed on each of the high-speed shafts, and a sidewall scaper to remove material from the mixing vessel wall ensuring efficient heat transfer during the mixing process. The mixing vessel is four gallons. The unit is also equipped with vacuum for degassing and has a filler loading system for adding fillers during the mixing process. The filler loading system is especially useful when adding fillers such as fumed silica which have a tendency to “fly around” when manually loading the mixing vessel.

References:

- Charles Ross & Son Company, Mixing Technology Insight #78

- Charles Ross & Son Company, Mixing Technology Insight #159

Leave a Reply